Creators rejoice! Thousands of Snapmaker users are in for a surprise as the company unveils yet another module to bring even more functionality to your fabrication-station. Released as a part of the Welcome to Snapmaker Wonderland virtual event to celebrate the ‘Maker’ spirit, the company unveiled their upgraded 10W High Power Laser Module, designed to easily fit onto any Snapmaker 2.0 (apart from the 150 models) or even the upgraded Snapmaker 2.0 AT and F models. The new laser cutting and engraving module packs even more of a punch, bringing the output up from 5W to a whopping 10W for power-users, prototypers, and educators. The Snapmaker 2.0 was designed to democratize in-house prototyping by simplifying professional-grade tech to make it consumer-friendly (you can read more about it here). With the new 10W High Power Laser Module, the user is empowered further, and is given new opportunities to put their ideas to the test.

Designer: Snapmaker

Click Here to Buy Now: $399 $459 ($60 off). Hurry, sale ends on Nov 28th.

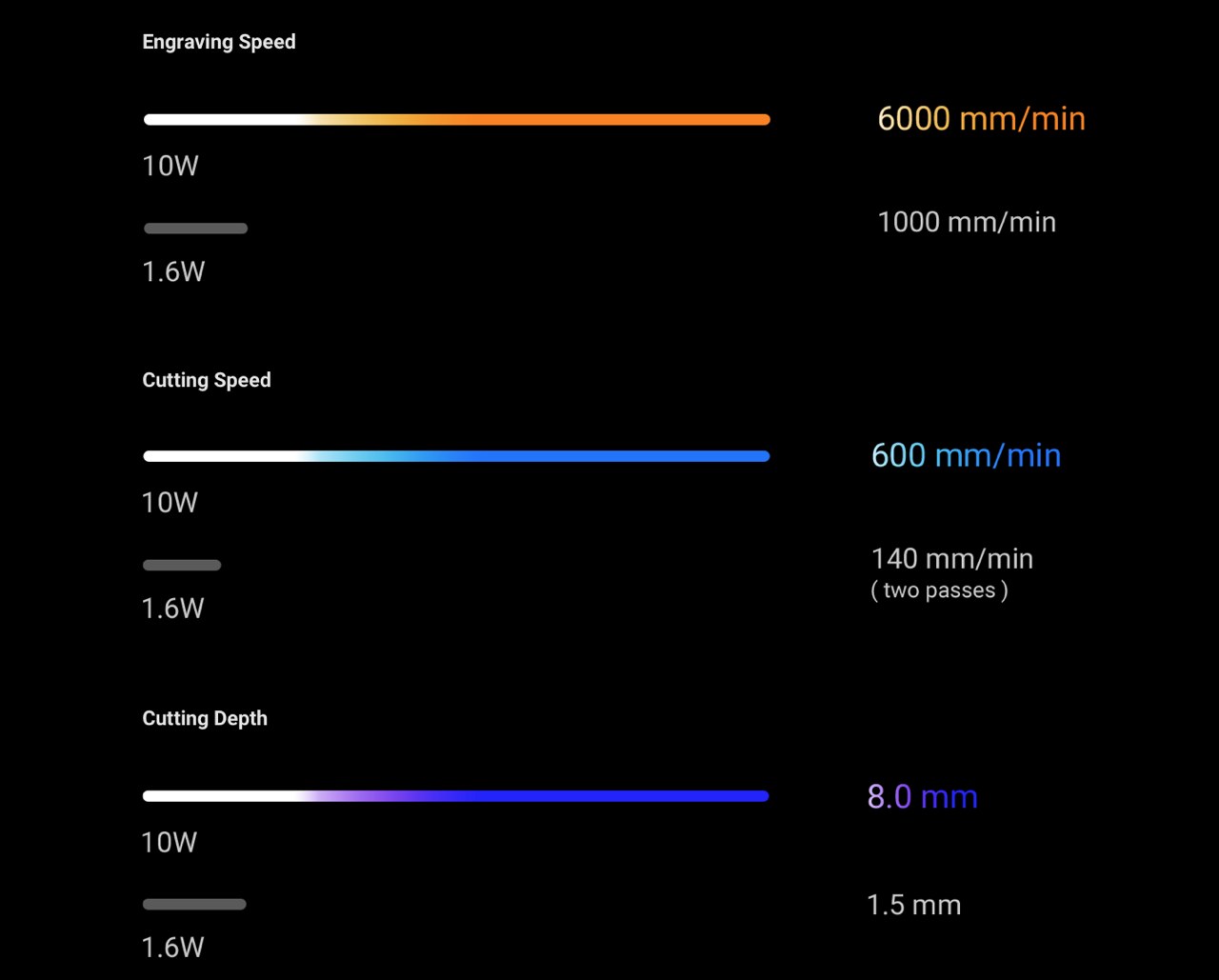

The 10W High Power Laser Module fits perfectly into Snapmaker’s modular ecosystem, integrating seamlessly into the Snapmaker 2.0’s workflow with a simple snap. The upgraded laser comes with a wider set of capabilities, boasting of more power, better efficiency, and an ability to work with even more materials. Installing the 10W High Power Laser Module is as simple as plugging it in place, and you’re quite literally ready to go. The upgraded laser module has a work speed of 6000 mm per minute, while being able to cut through basswoods as thick as 8mm. To put it in perspective, it’s about 8 times more capable than a standard 1.6W laser engraver/cutter, with industrial-level speeds that allow you to practically set up a factory line, pushing out product after product in mere minutes. On the capability front, the 10W High Power Laser Module supports a whole variety of materials for engraving as well as cutting, along with all the popular file formats for the job (.stl, .svg, .png, .jpg, .jpeg, .bmp, .dxf) for your jobs.

For engraving/etching, Snapmaker recommends using the laser module for a range of natural and engineered woods, painted metal, copper clad laminate, SPTE, stainless steel, anodized aluminum, acrylic, dark glass, slate, brick, ceramic, jade, marble, shale, leather, fabric, canvas, corrugated fiberboard, and cardboard. The 10W laser is rated for laser-cutting materials like Pinewood, plywood, beechwood, walnut, bamboo, MDF, black and red acrylic, leather, fabric, canvas, corrugated fiberboard, and cardboard. This makes the Snapmaker 2.0 perfect for designing gifts, cards, and even packaging all within one machine!

Here is a comparison between 1.6W and 10W laser, taking 1.5 mm-thick basswood engraving and cutting as an example.

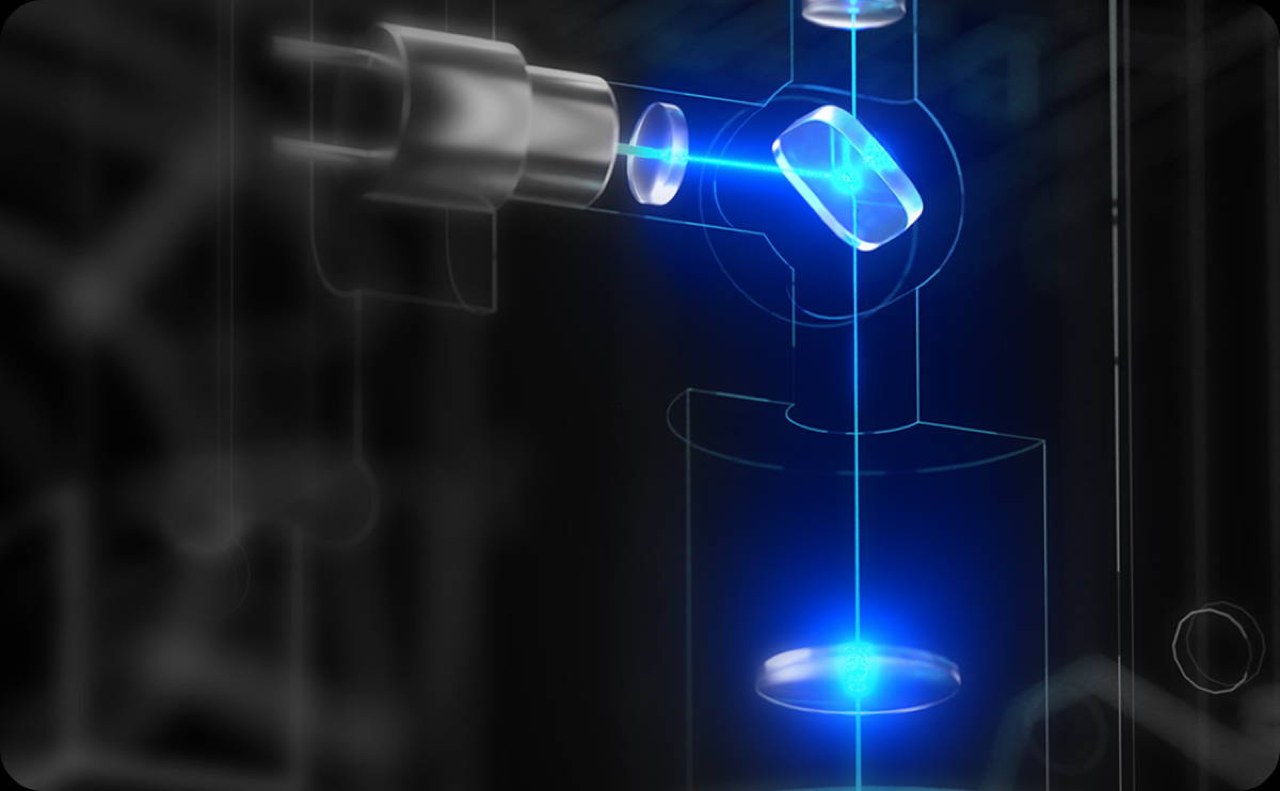

With the Fast-axis Collimating (FAC) lenses embedded in the two laser diodes, the module first compresses the laser spot of each laser diodes. Then it combines the laser beams of the two laser diodes using the beam combining technology, resulting in a higher output power and an ultra-fine laser focus (0.05 mm × 0.2 mm), which allows for higher energy density. Smaller laser focus and higher power deliver high-quality laser works with impeccable details.

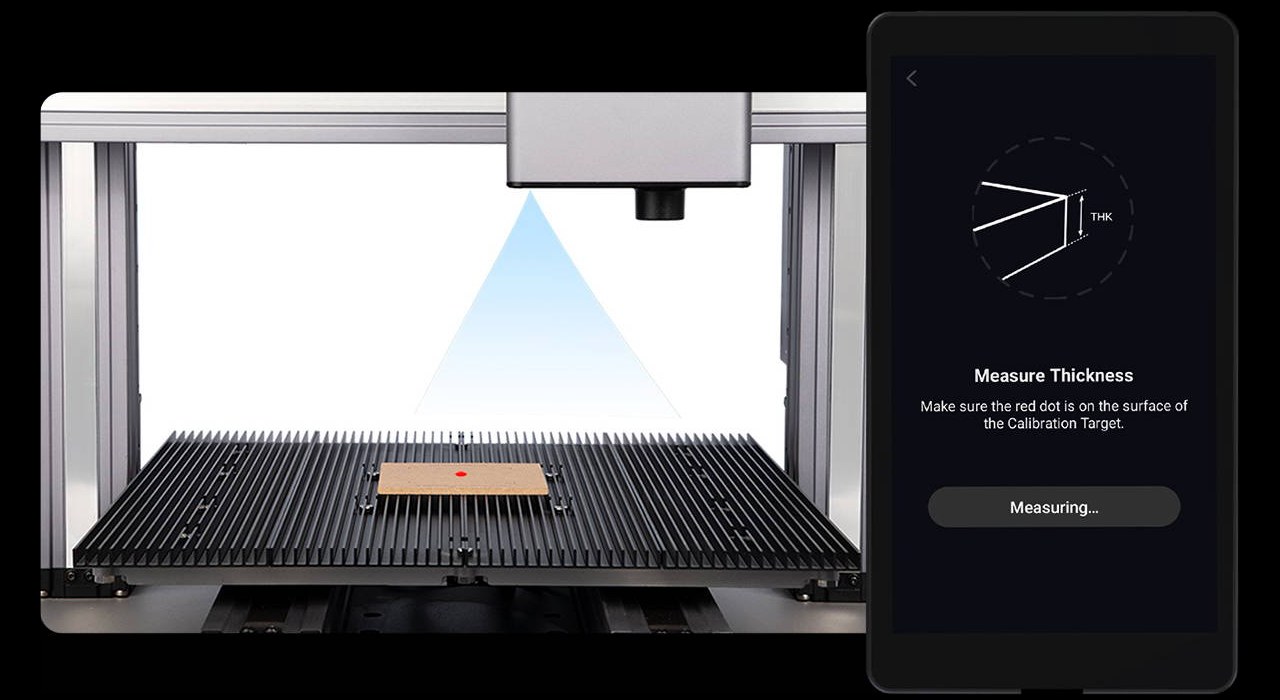

Autofocus in seconds. Place your material on the platform, and the module will calculate it for you. Thanks to the triangulation technique, the module is able to measure the thickness of your material by obtaining a few sets of data on the camera and light emitter.

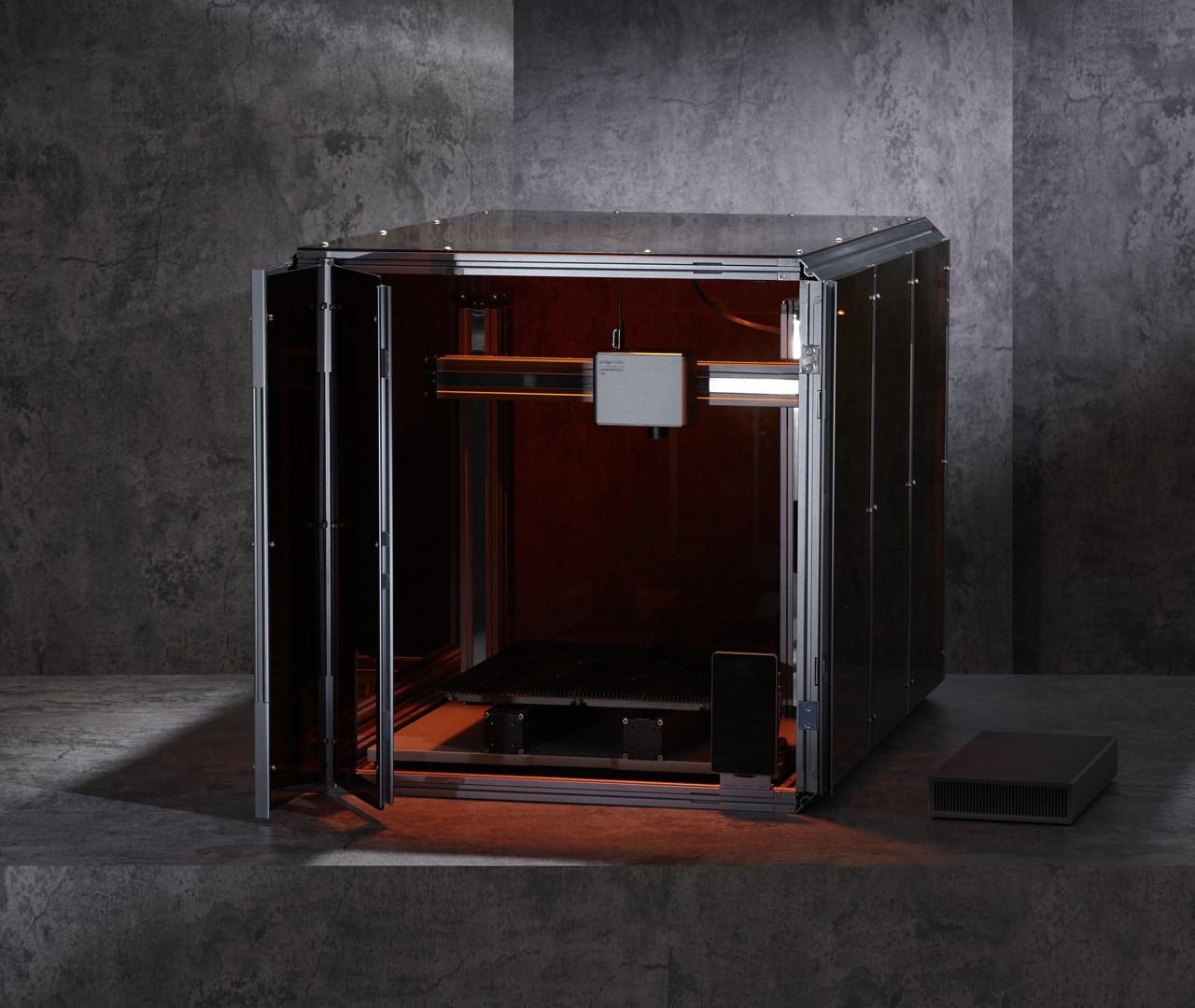

Unveiled just this month, the 10W High Power Laser Module boasts of new capabilities, including an improved auto-focus, as well as an upgraded camera, that captures the work surface and helps you visualize and align your print/etch/outline perfectly onto the surface for perfect results. The new laser also has an orientation detection sensor that makes sure the module’s correctly installed, so that the laser never points out of the work area, risking damaging equipment or hurting bystanders (Snapmaker also recommends using the laser module with the Snapmaker 2.0 Enclosure). Like all of Snapmaker’s attachments, the new 10W High Power Laser Module is compatible with Snapmaker Luban, a custom software that offers an intelligent, visualized G-Code-generated workflow to help you set up your projects with ease, along with a revolutionary new 3D to 2D feature that lets you turn 3D models into 2D vectors that the laser module can cut out of sheet material for you. A standard across all of Snapmaker’s devices, Luban allows existing users to upgrade to the newer modules without worrying about a new learning curve. Calibrating your machine is simple too, with Snapmaker’s Original Assistant (on its screen-module), which guides users through the relatively easy process.

Like all of Snapmaker 2.0’s components, the 10W High Power Laser Module aims at bringing out the best in the machine’s capabilities and the user’s imagination. The 10W High Power Laser Module is rated for high durability, with two separate blowing systems for its PCBA and its laser diode to make sure the diode is properly cooled off during and after use, and overheat protection that automatically pauses the job whenever its temperature sensor detects a higher than normal working temperature. Once the temperature falls back into the normal range, users can resume their job on the Touchscreen. Under proper use, the lifespan of the module is rated for as long as 10,000 hours, and a 1-year warranty on the module is a given. Moreover, the 10W High Power Laser Module builds on the infinite capabilities of the Snapmaker 2.0 ecosystem, while also promising to be compatible with all future Snapmaker 2.0 machines that the company releases. You can grab the 10W High Power Laser Module at $399 (original price $459) or any of Snapmaker’s all-in-one machines for a discount below, just use the coupon code BYD100 for a $100 discount on purchases above $1100.

Click Here to Buy Now: $399 $459 (13% off). Hurry, sale ends on Nov 28th.