Recycled designs are the need for today! Since the world is drastically changing, and that is affecting the way we live and function. Although the irony is that the world is drastically changing because of our unhealthy practices and us! It’s now imperative to live more carefully and consciously. And one way to do this is by opting for recycled product designs! Designers and creators are coming up with recycled alternatives for almost everything! Every product that is necessary and utilized by us in our everyday routine has an eco-friendly alternative to it. Replacing our usual mass-produced designs with these greener options will make a huge difference to the environment and Mother Earth! From a recycled stool made from 4000 disposable face masks to a modular flotation device made from recycled plastic bottles – we’ve curated a whole collection of recycled products that will have major functionality in our daily lives.

UK-based designer Joe Slatter noticed the blue and white litter all over the streets of London and decided to do something about it, weaving disinfected masks from the streets into what he calls the Veil Stool. After collecting close to 4,000 masks from the streets of London, Slatter disinfected them by coating them in ozone spray and leaving them out in direct sunlight for four weeks. Once they were sanitized and prepared for the next step, an experimental period followed that led to Slatter discovering that 3-ply face masks, the blue and white disposable ones, could be spun into a soft yarn or melted down into a dense polypropylene structure. The stool’s final form finds a threaded, cushioned seat made from facemasks spun into a yarn mounted on top of three short stool legs hardened from melted face masks.

The Saviour is a modular system of interlocking tubes that help you create flotation devices. The tubes don’t float themselves, but rather, allow you to attach multiple plastic bottles around the rim to help the overall product stay afloat. You can either assemble the Saviour to form a U-shaped training apparatus or join multiple pieces to close the U, turning it into an O-shaped device that children can use as a tube. The Saviour is low-cost, and its individual modules can easily be 3D-printed based on demand. Moreover, it utilizes plastic bottles, helping recycle waste into something vastly more useful. If a plastic bottle gets damaged, it can easily be replaced with another one, allowing you to quickly upgrade/repair your training gear.

The XpreSole® Panto comes with a slick contemporary design and a pretty impressive list of features. The rain boots are waterproof, dirt-proof, breathable, lightweight, machine-washable, have high traction, and are sustainably made by recycling coffee grounds from as much as 15 cups of coffee per pair of boots. If that wasn’t enough, the XpreSole Panto also went on to win the Red Dot Best of Best, the iF Design Award, and the A’ Design award this year. Is coffee all set to replace leather or PU leather as a footwear material? The folks at CCILU believe that the XpreSole Panto makes a pretty compelling case.

A team of designers based in China unveiled their own disposable home product, a recycled paper toothbrush called Cycle that even comes complete with biodegradable toothpaste. Made from food-grade recycled paper, Cycle boasts an environmentally friendly design that’s as physically safe as it is biodegradable. Cycle comes in sets, complete with a protective covering for the toothbrush’s bristles and a detachable sachet of toothpaste. Before use, consumers can remove the protective covering, and rip off the attached packet of toothpaste and once the job is done, Cycle can then be discarded without fear of harming the environment. Packaged in sets of four or five, Cycle makes the ideal travel companion for short camping trips or even indoor getaways that call for a couple of days’ worth of brushing your teeth.

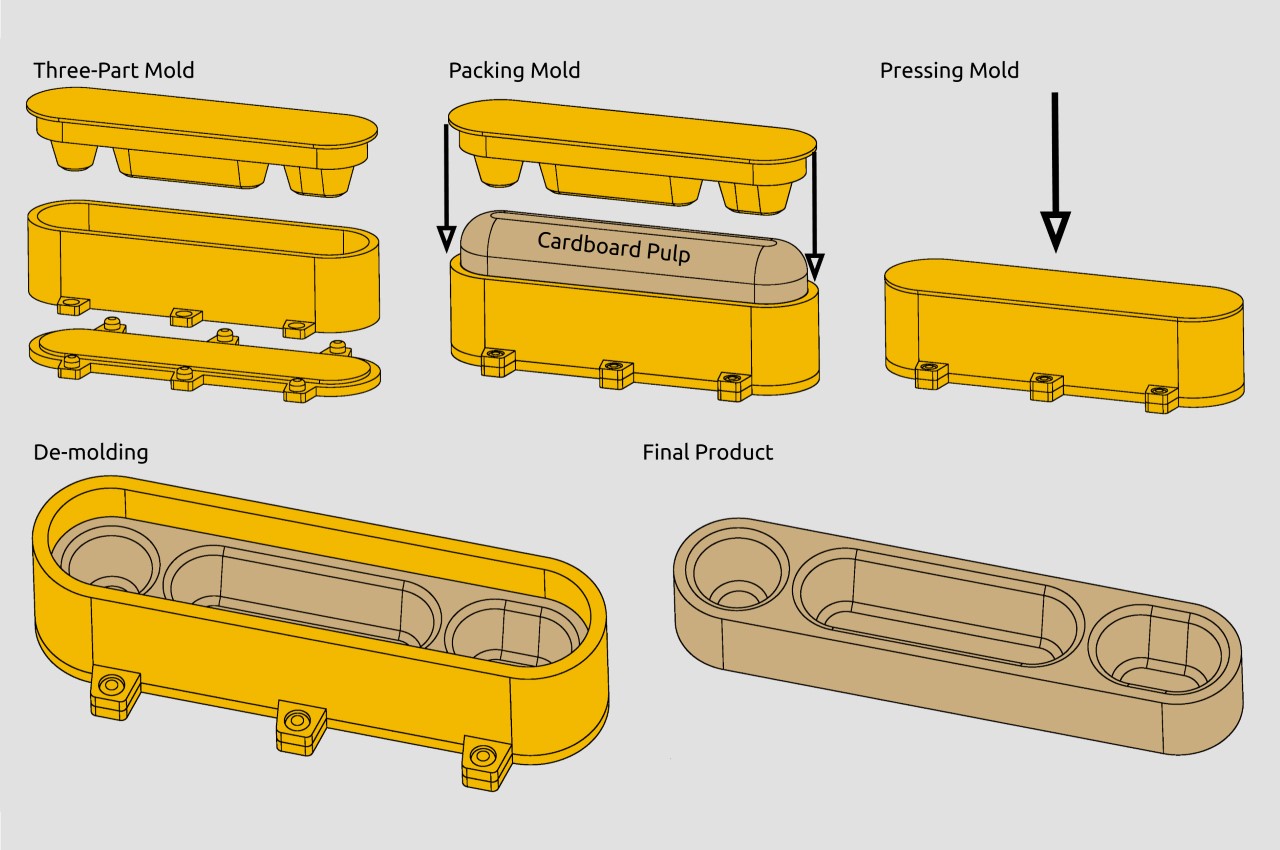

If you’re familiar with how injection-molded plastic products are made, the process for working with cardboard pulp is rather similar. You’ve got liquidized raw materials that fit inside a mold, which helps form and compress the fluid mass into a tightly packed design. Once ready, the mold separates into its different parts, releasing the final product. XYZAidan started by first preparing his raw materials. Grabbing any cardboard he could find and finely shredding it in a paper shredder, XYZAidan then proceeded to blend the cardboard strips with water and a water-soluble binder. To keep things eco-friendly and biodegradable, he opted against synthetic PVA glue for a more natural rice paste, made by mushing cooked rice in water over a stovetop to create a starchy pulp that would hold the cardboard fibers together in the mold.

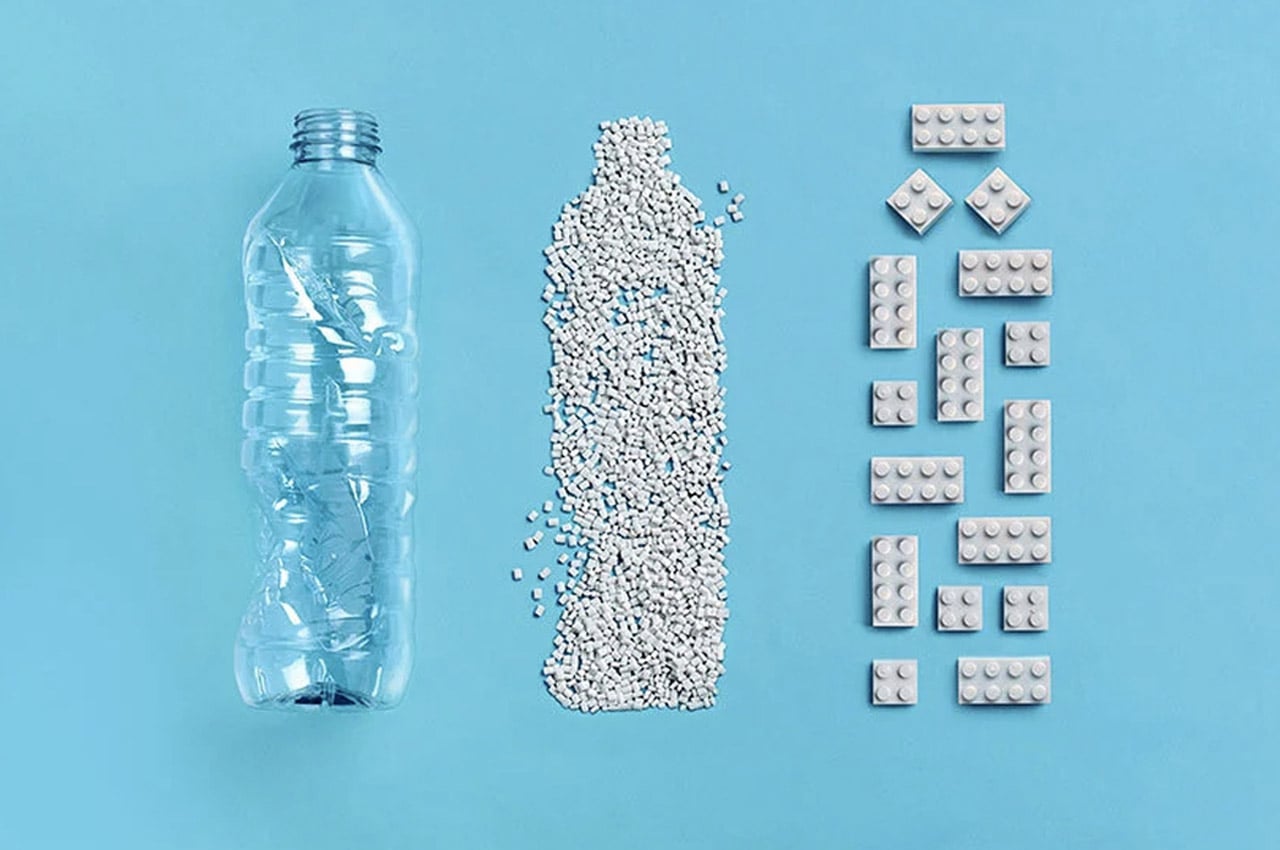

Since 2018, LEGO has been making strides towards sustainability initiatives including removing single-use plastic from their boxes and producing specialty elements from bio-polyethylene, a natural polymer sourced from sugarcane. Today, the iconic toy company reveals its latest sustainability effort, a prototype brick produced from recycled PET plastic. Derived from discarded plastic bottles, LEGO’s new sustainable prototype marks the culmination of three years worth of testing over 250 variations of PET plastics. The result, a LEGO brick constructed entirely from recycled materials that meet an array of different requirements, including safety, quality, play, and perhaps most exciting, clutch power.

Titled the Pebble, these gorgeously vivid and funky cutlery tools are a collaboration between Pentatonic and i am OTHER, a creative collective assembled by Pharrell, and are made mostly from recycled materials. The unusually vibrant cutlery set is named after the pebble-shaped container it comes in. The colored container is made using plastic recycled from music CDs, and perfectly houses a spoon, knife, fork, a pair of chopsticks, and even a collapsible drinking straw. Plastic handles for the cutlery are crafted from recycled food packaging, while the cutlery themselves are crafted from steel, with a highly durable anodized titanium coating for strength as well as to give the cutlery their unmistakable vibrant purple hue.

![]()

![]()

The choice of material for Chipolo’s latest Ocean Series trackers is quite poetic if you ask me. The trackers help you keep track of your personal belongings – things of value to you – but ironically or poetically enough, they’re made from the things you don’t consider valuable… single-use plastics. Through a strategic partnership with Oceanworks.co to source ocean-based plastic waste, the Chipolo ONE Ocean tracking device comes made with a recycled plastic body. Fishing nets, trawls, and ropes floating in the sea are collected in the shallow areas of the ocean near the shoreline, before being cleaned, treated, and turned into polypropylene plastic pellets. These pellets are the primary raw material used to create the outer body of Chipolo’s tracking device.

With an appearance that almost mimics the fragmented beauty of terrazzo, the PVC Bench by UAE-based designer Ammar Kalo relies on a new type of composite material developed by recycling old PVC drainpipes. Designed as a two-person bench, the seating design comes with Kalo’s signature organic aesthetic featuring legs and a base-support made from walnut wood, and its crown jewel, the seating platform, made from multiple PVC parts suspended in a tinted resin. The transparent resin reveals the multiple PVC shards in a way that seems to contrast the bench’s overall smooth, soft, organic design. Its multiple shards create a beautiful interplay of light and shadows, forming a surface that has a unique pattern, just like the wood-grain on the walnut members below it. The bench, like most of Kalo’s furniture, comes with simple joineries that don’t require any extra fasteners or binders.

The Huskeecup is the coffee equivalent of drinking a coconut cocktail out of a coconut… No, seriously! Each Huskeecup is, in fact, made from recycled coffee husks combined with a binding agent and molded into a reusable cup that’s impact-resistant, non-toxic, dishwasher-friendly, and uniquely pleasing to look at or even smell! An estimate of 600 billion disposable coffee cups are produced worldwide each year, 99.75% of which are dumped in a landfill or the oceans without being recycled. What the Huskeecup does is solve that problem, while also looking at the humble coffee bean as a raw material. The fine folk at Huskee gather coffee husks discarded in the roasting process, and pulverize them before binding them together with a biopolymer and finally forming them into cups.