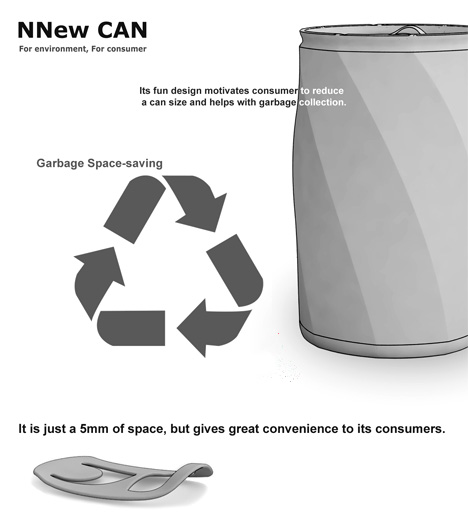

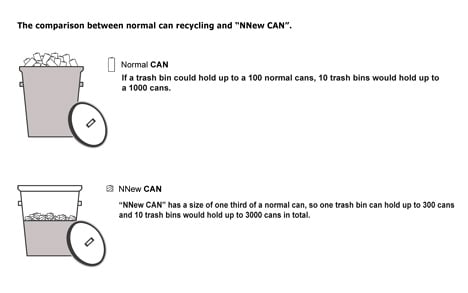

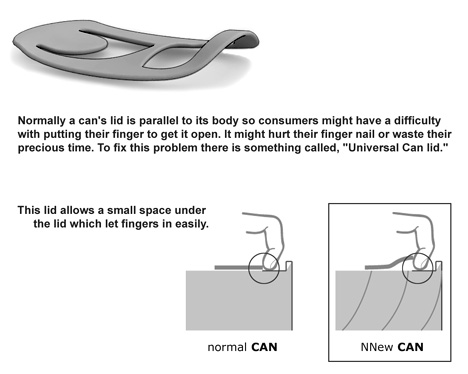

There are two things make the NNew Can stand out; one it has a deliberate spiral shape and two its opening-clip has an uplifted indent. The reason for the spiral shape is obvious, it makes it easier for you to twist and crush the can with hand and dump it into the trashcan. And the reason for the indent in the clip is so that you can open the can easily without chipping a nail. I endorse the second reason wholeheartedly coz I always manage to clip mine while opening my soda-can!

Designers: Jiwoon Park & Kwenyoung Choi