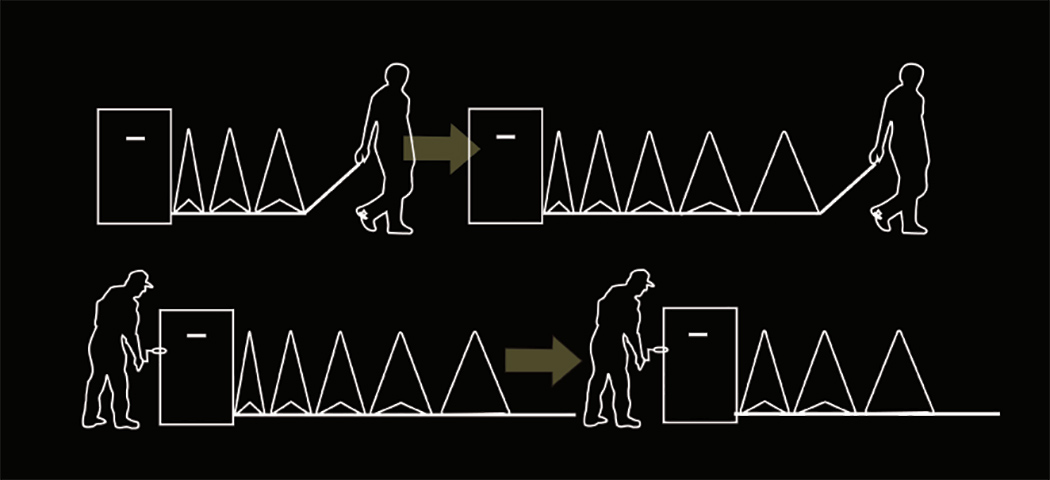

Setting up traditional traffic warning cones at a roadwork site takes a long time because the cones are heavy and cumbersome. Warning Cone offers much greater convenience to construction workers. A set of Warning Cones can be expanded (unfolded) easily by pulling out the extendable base. After use, the ‘cones’ can be compressed and placed back in the storage box, saving both time and space.

Designer: Asia University