In collaboration with OTTOBO Robotics, product and car designer Berk Kaplan developed a concept design for a task robot that integrates smart technology to streamline ergonomics and package-carrying flexibility.

Each day, it feels like we’re getting closer to a future where robots will walk among us. Advancements in smart technology and Artificial Intelligence have streamlined and catapulted robot development to the forefront of our minds. Wrocław-based car and product designer Berk Kaplan recently teamed up with OTTOBO Robotics to develop a concept design for their smart task robot.

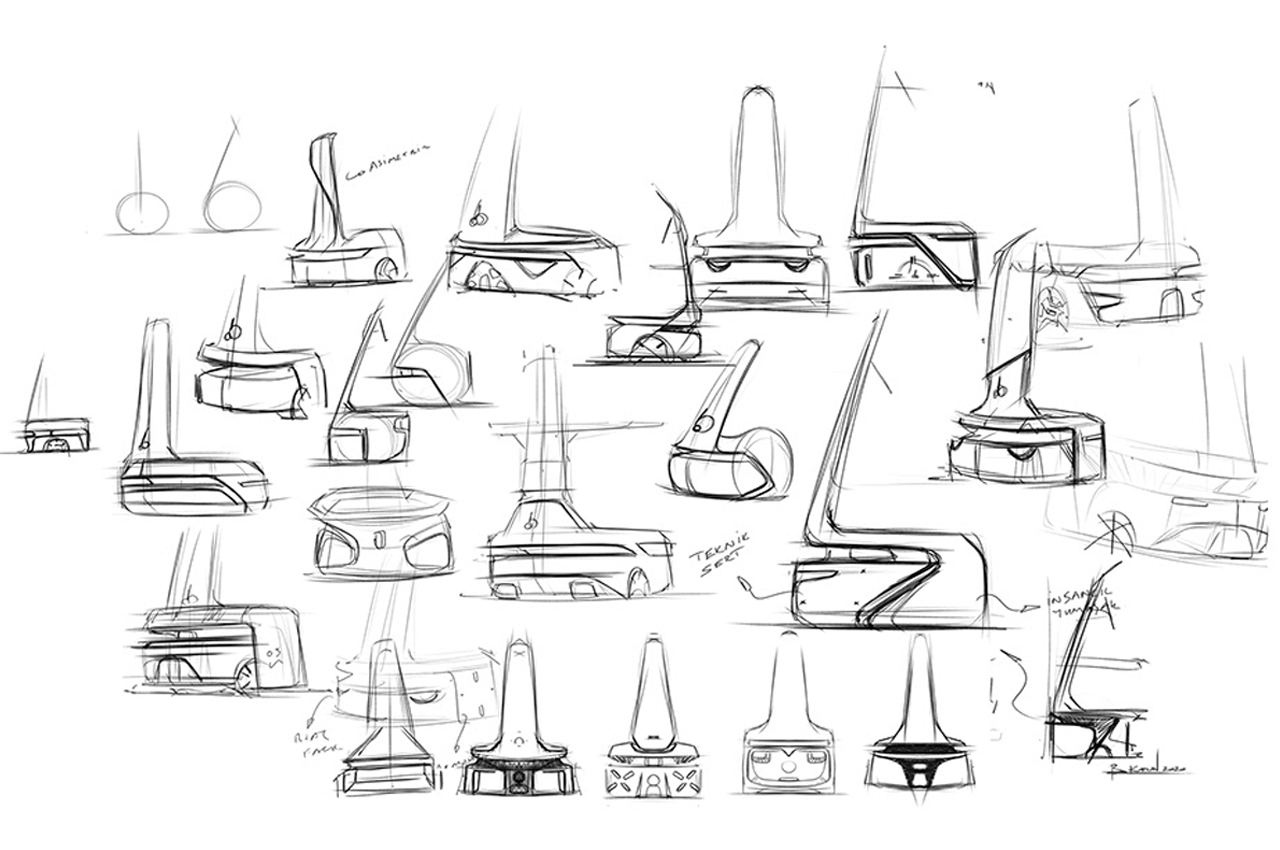

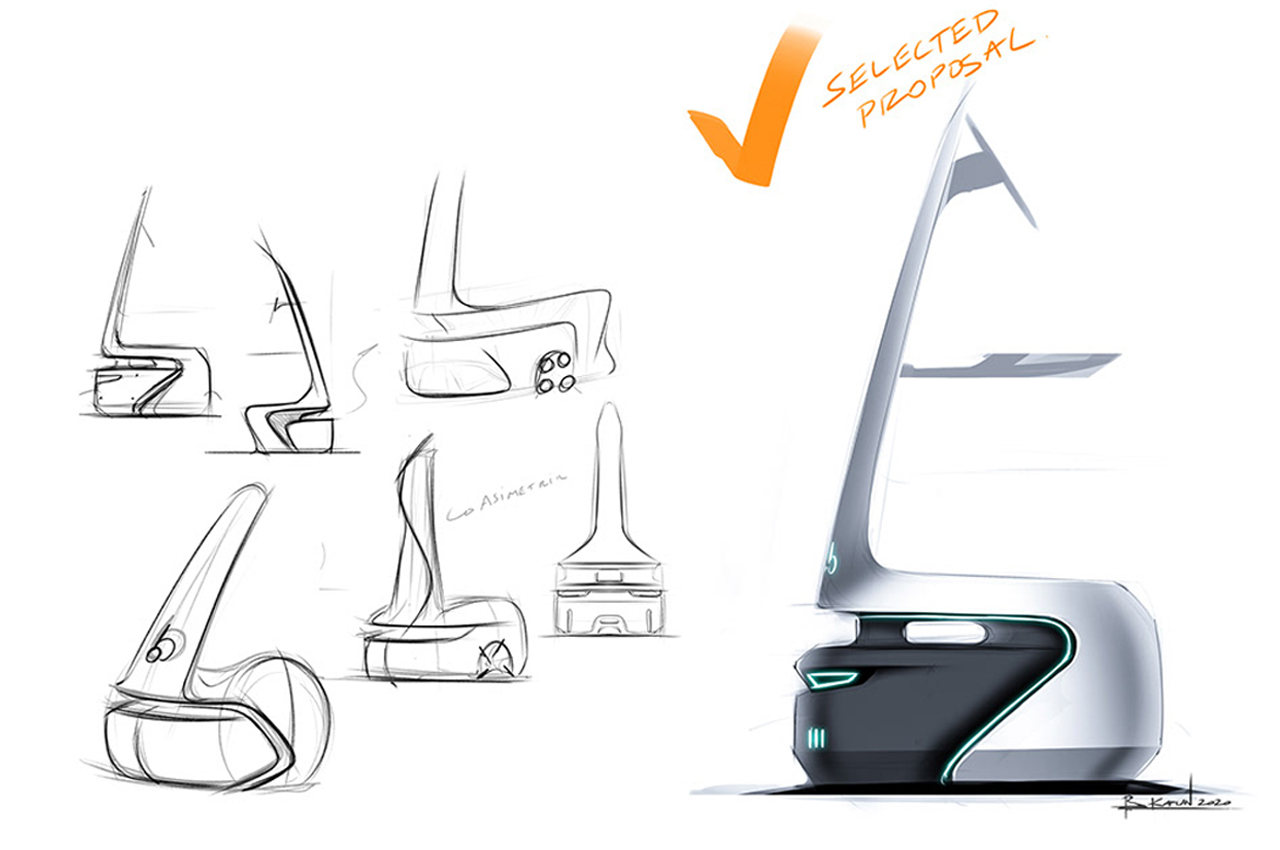

During the beginning stage of the concept design phase, Kaplan first conducted his own research to settle on the overall mood and personality of the robot. Following the research period, Kaplan sat down to sketch outlines of his robot in development, toying around with practical elements and aesthetic touches. The first proposal envisioned the robot with both a hard outer shell and inner core, giving it a tough, hardworking personality and weighty body.

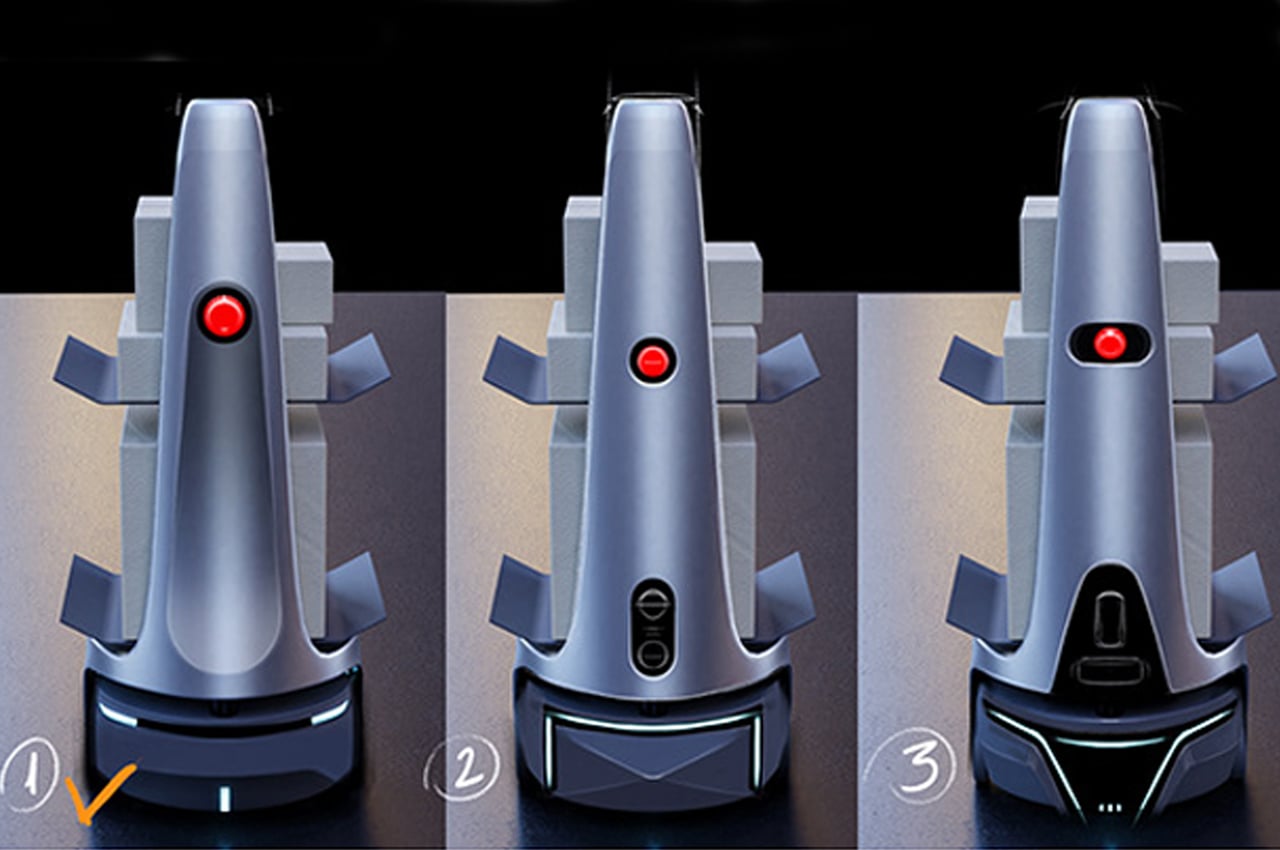

Where the first proposal found durability in a tough exterior and interior, the third proposal from Kaplan wrapped the robot in a soft outer shell to cover the robot’s soft interior core. The second proposal, which Kaplan and OTTOBO Robotics ultimately chose as the concept design’s final form, conceived the robot with a soft outer shell and hard inner core for a cushioned tactile experience, outfitting the robot with a friendly and approachable disposition.

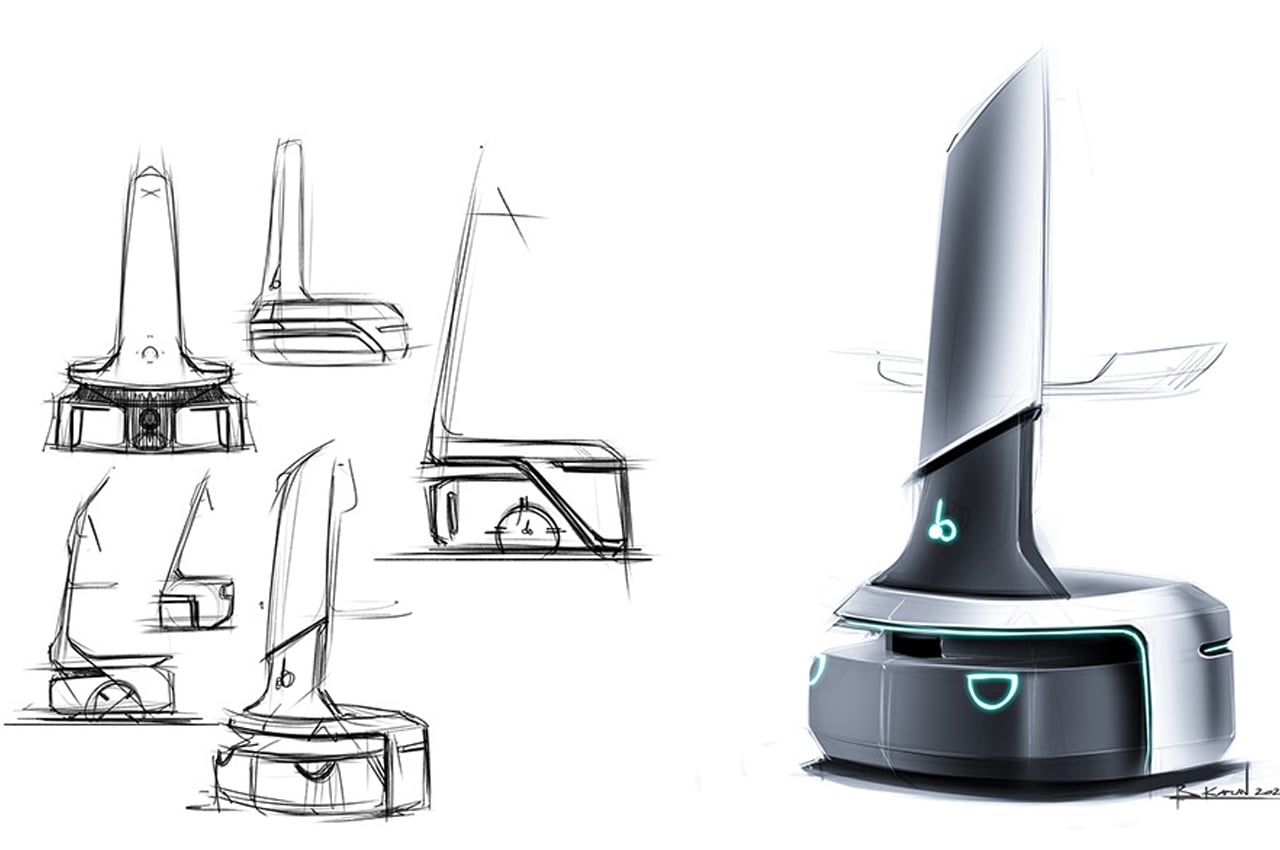

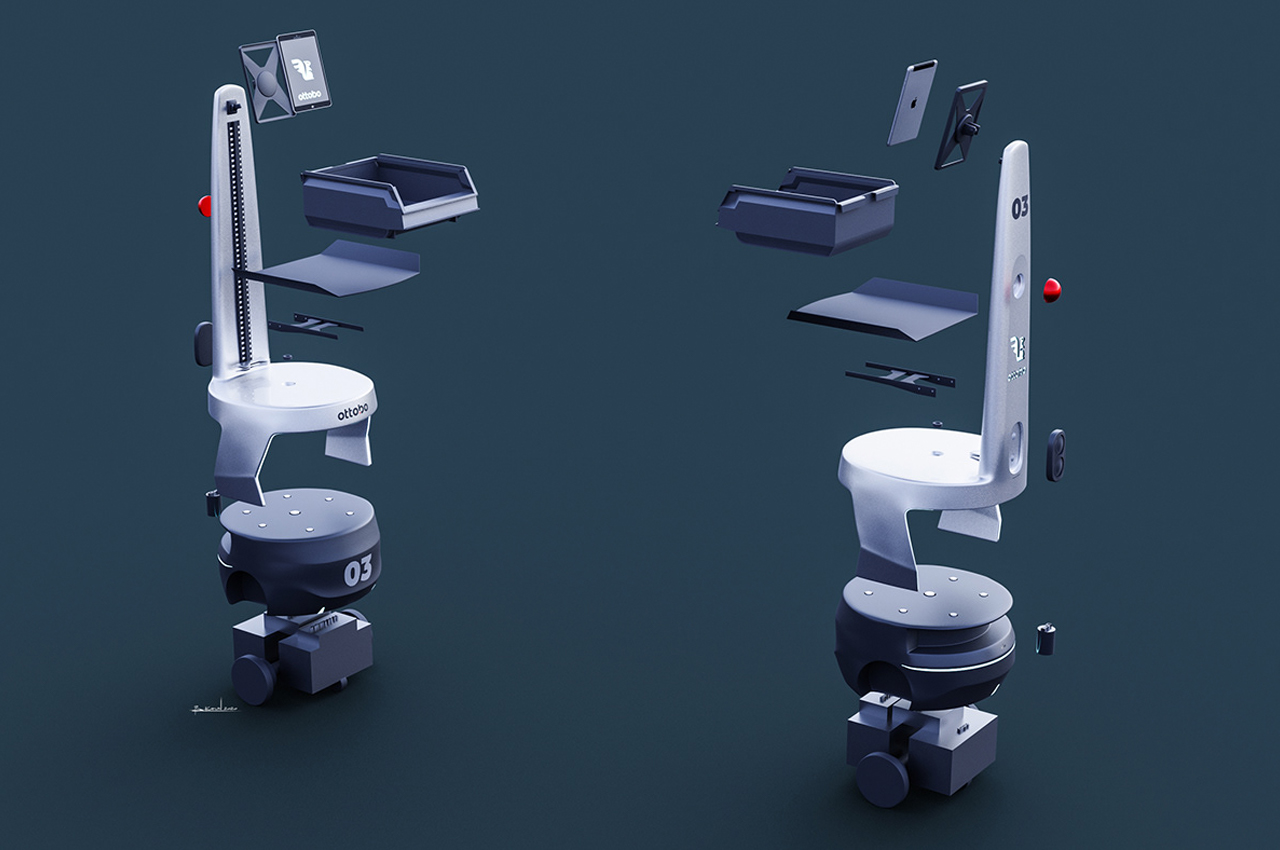

Once the final conceptual form was chosen by the OTTOBO Robotics team and Kaplan, 3D models were created to further develop the robot from every angle. Working with 3D models of the robot allows Kaplan to find the best ways to optimize the robot’s ergonomics and package flexibility. During this stage, more technical specifications were chosen for the robot, more specifically deciphering how smart technology would be built into the room to ensure its operability. Following this concept design phase, Kaplan and the OTTOBO Robotics team are looking forward to future production.

Designer: Berk Kaplan x OTTOBO Robotics

Berk Kaplan used 3D models after deciding on the robot’s conceptual final form to understand its shape from every angle.

Using 3D technology, Kaplan deciphered how to best optimize the robot’s package-carrying flexibility.

After settling on its form and creating matching 3D models, Kaplan added aesthetic details like branding and logos. Production coming soon!