WARNING: The following design may inspire self loathing, resentment and/or simple jealousy that you did not think of this first. Deal with it.

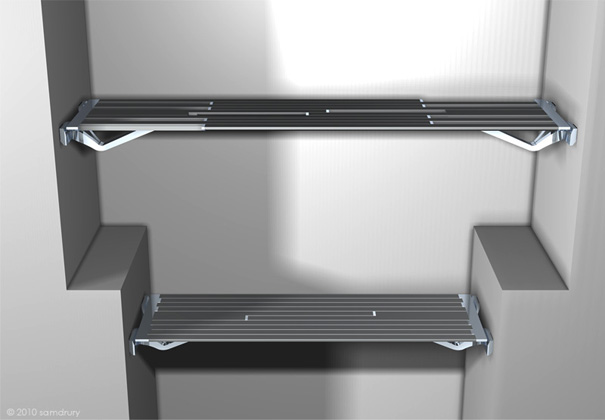

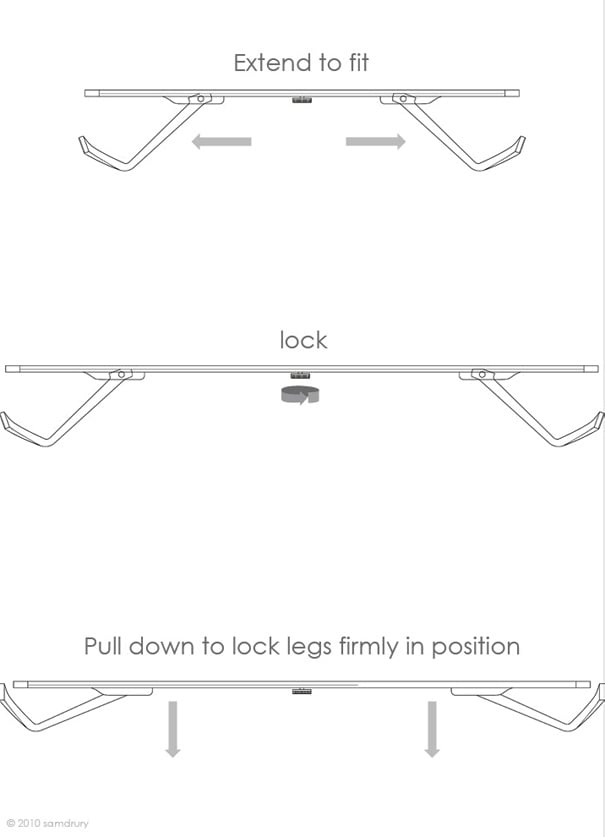

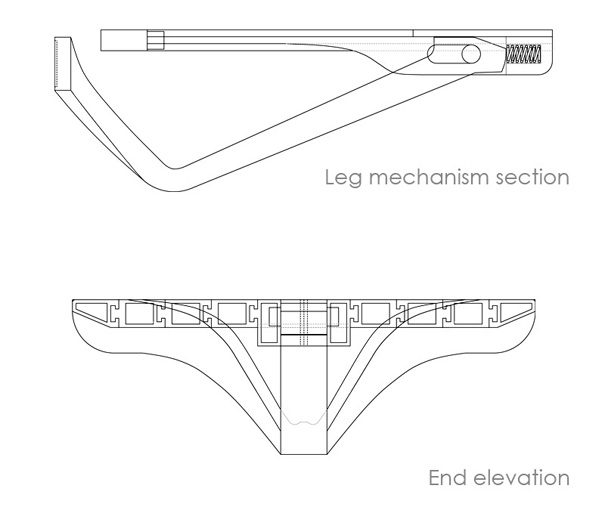

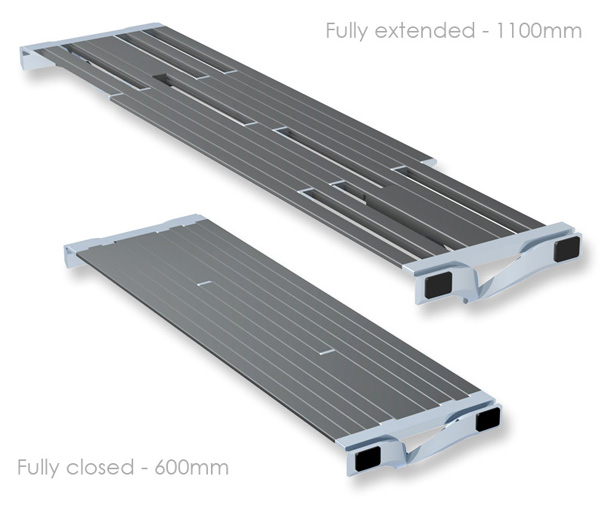

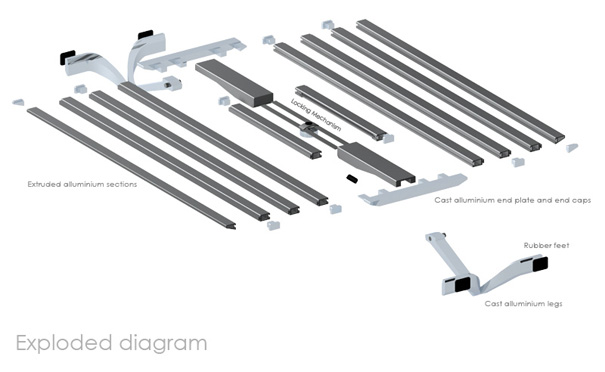

From the Yanko Obvious Files comes this latest creation from designer Sam Drury. The “Self Supporting Shelf” is a masterfully simple idea. It is a telescopic shelf that extends between two flat surfaces for a perfect fit every time. No screws, no nails no messy clean-up. The shelf can be moved at whim with zero damage to your walls. With its cam and cantilever mechanism, the more pulp fiction you pile on, the sturdier the shelf becomes. I can almost hear the late night TV commercials now.

Designer: Sam Drury