3D printing is one of those revolutionary technologies that truly changed the world even years after it became a hot topic. Whether you’re a lone hobbyist or a small company, these seemingly magical boxes are able to bring ideas and dreams to life or at least help jump-start the process of testing and refinement. Despite its amazing achievements, 3D printing technology is actually still at its puberty stage, with plenty of room for growth and, more importantly, experimentation. Fortunately, there are plenty of designers, engineers, and dreamers who are willing and eager to push the boundaries of what 3D printers are able to accomplish, whether it’s in manufacturing, food, or design. This experimental shoe, for example, makes you look like you’re wearing some sort of sci-fi wireframe footwear, and its complex structure really puts 3D printers to the test.

Designer: Matthew Blunt

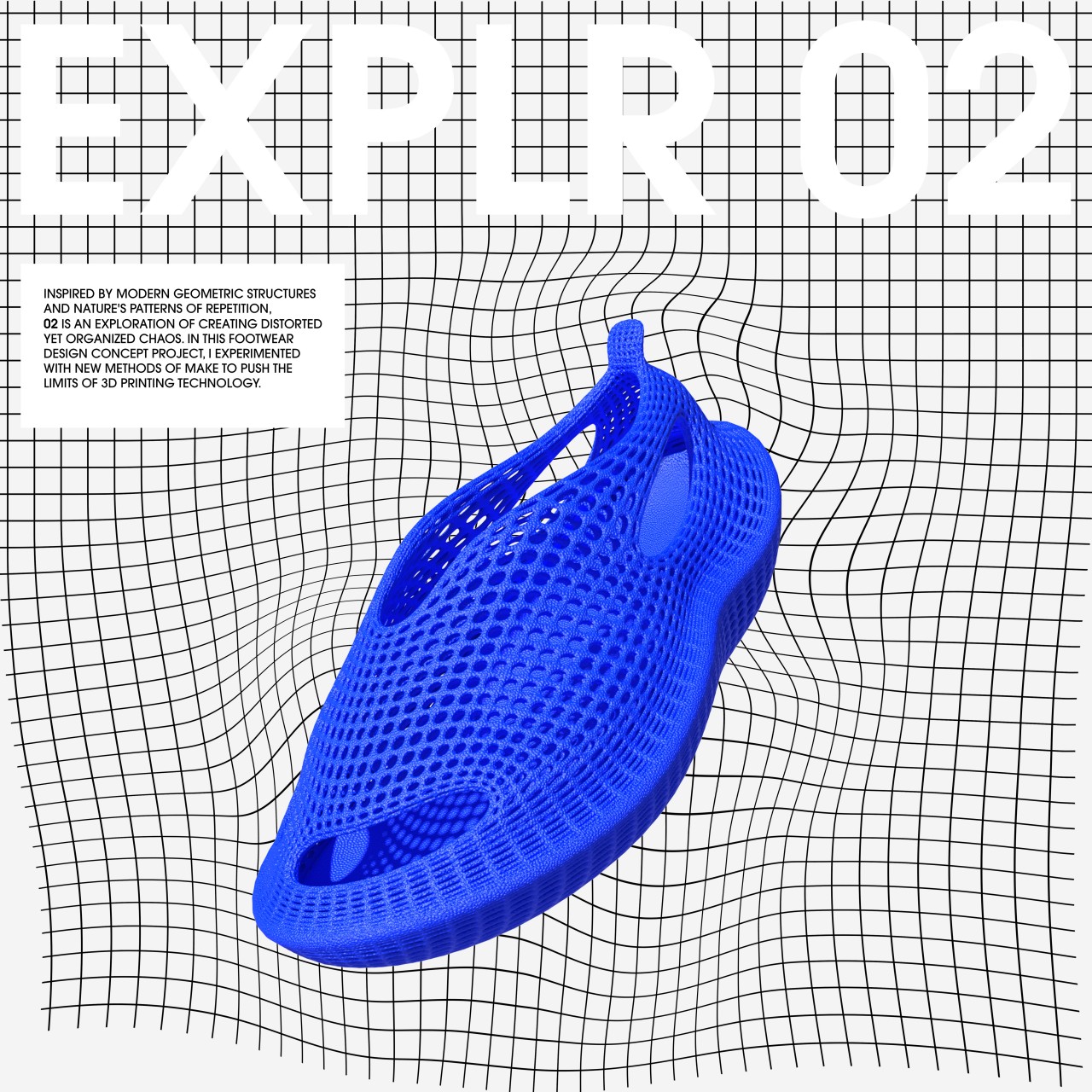

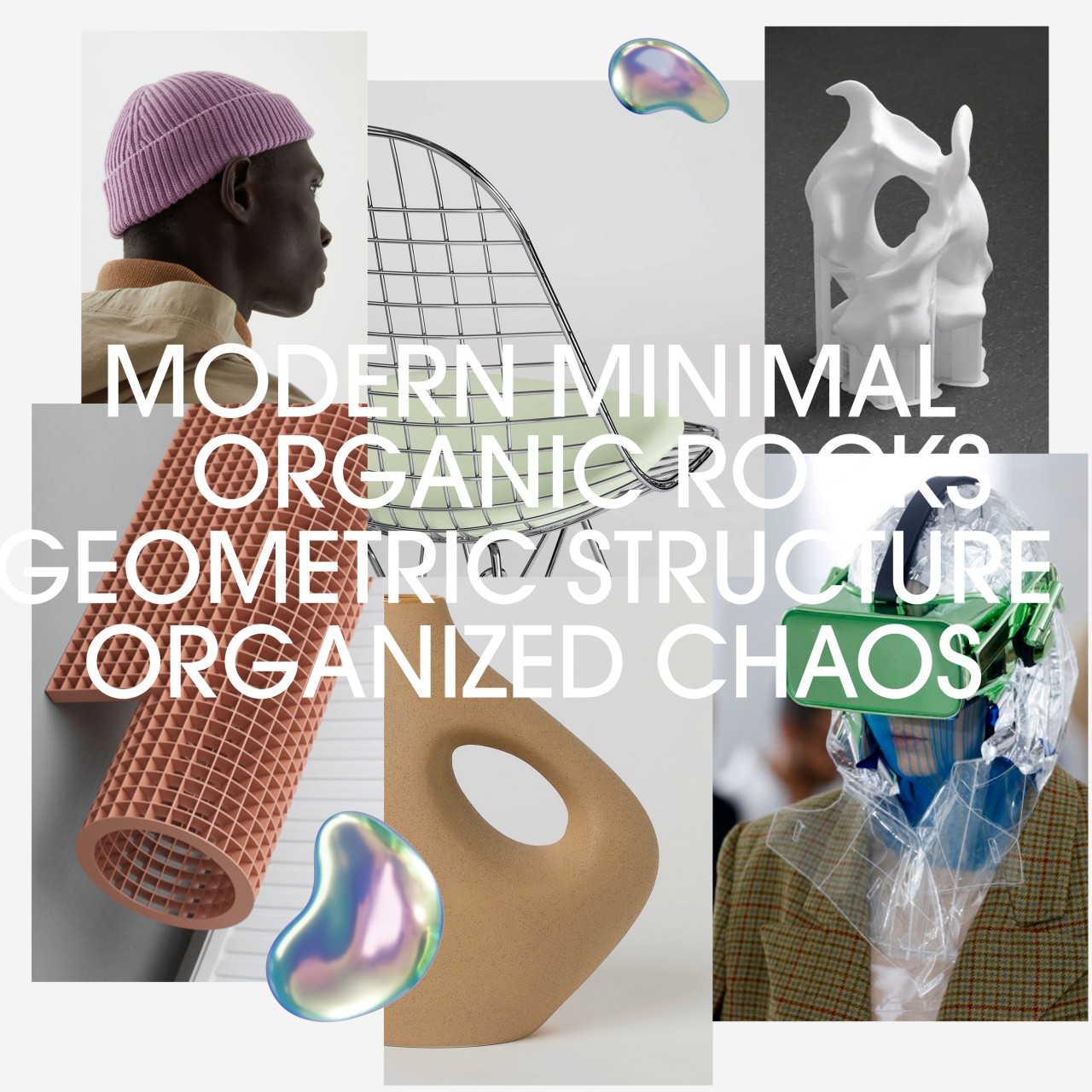

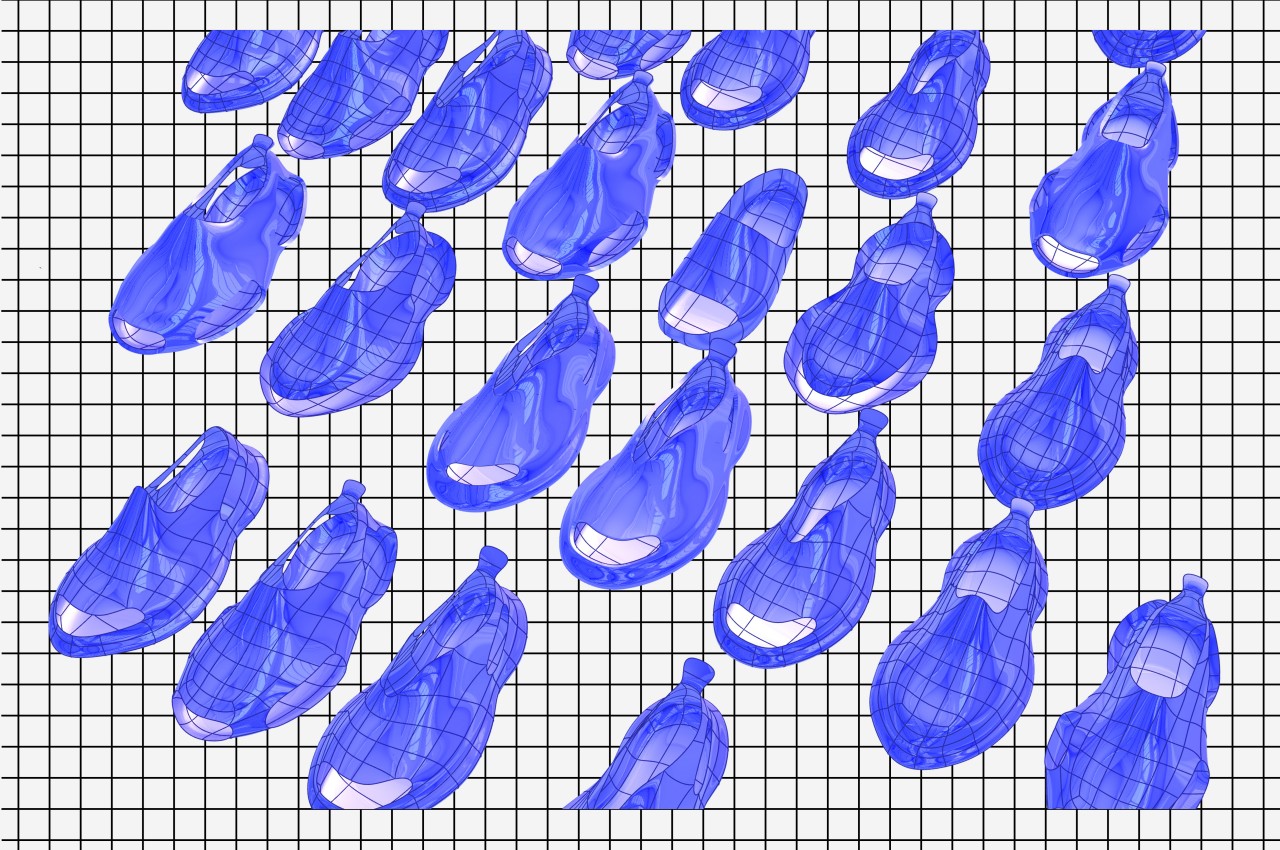

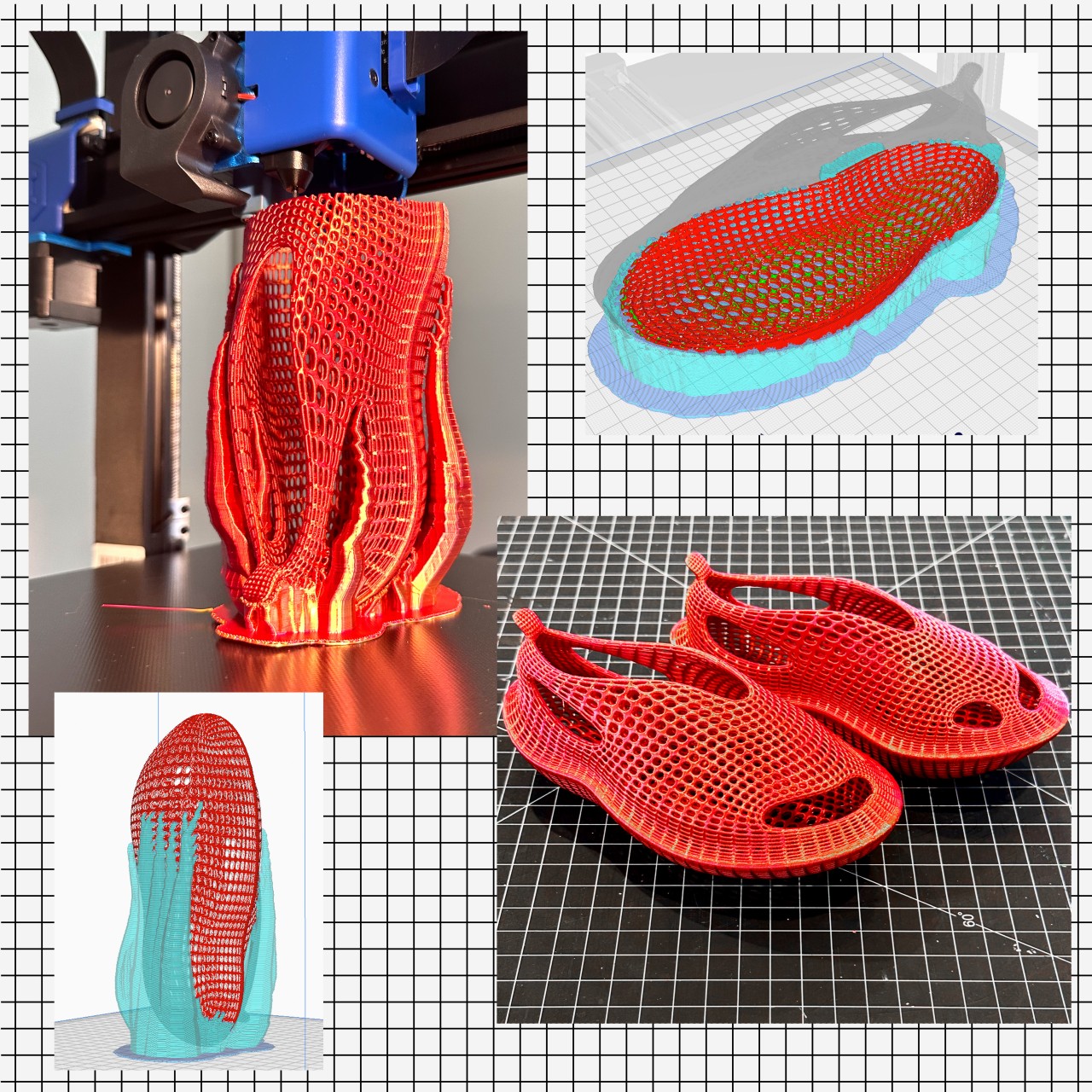

In the beginning, 3D printers naturally had very limited capabilities, able to build only closed forms or relatively simple shapes. The materials used would be variants of plastic that would be unsuitable for anything but the gentlest and driest applications. Over time, though, 3D printing has moved onto a wider variety of materials, like metal or even chocolate, and more complicated structures. EXPLR 02 builds on top of that to create a design that is one part made of geometric structures and another part inspired by nature.

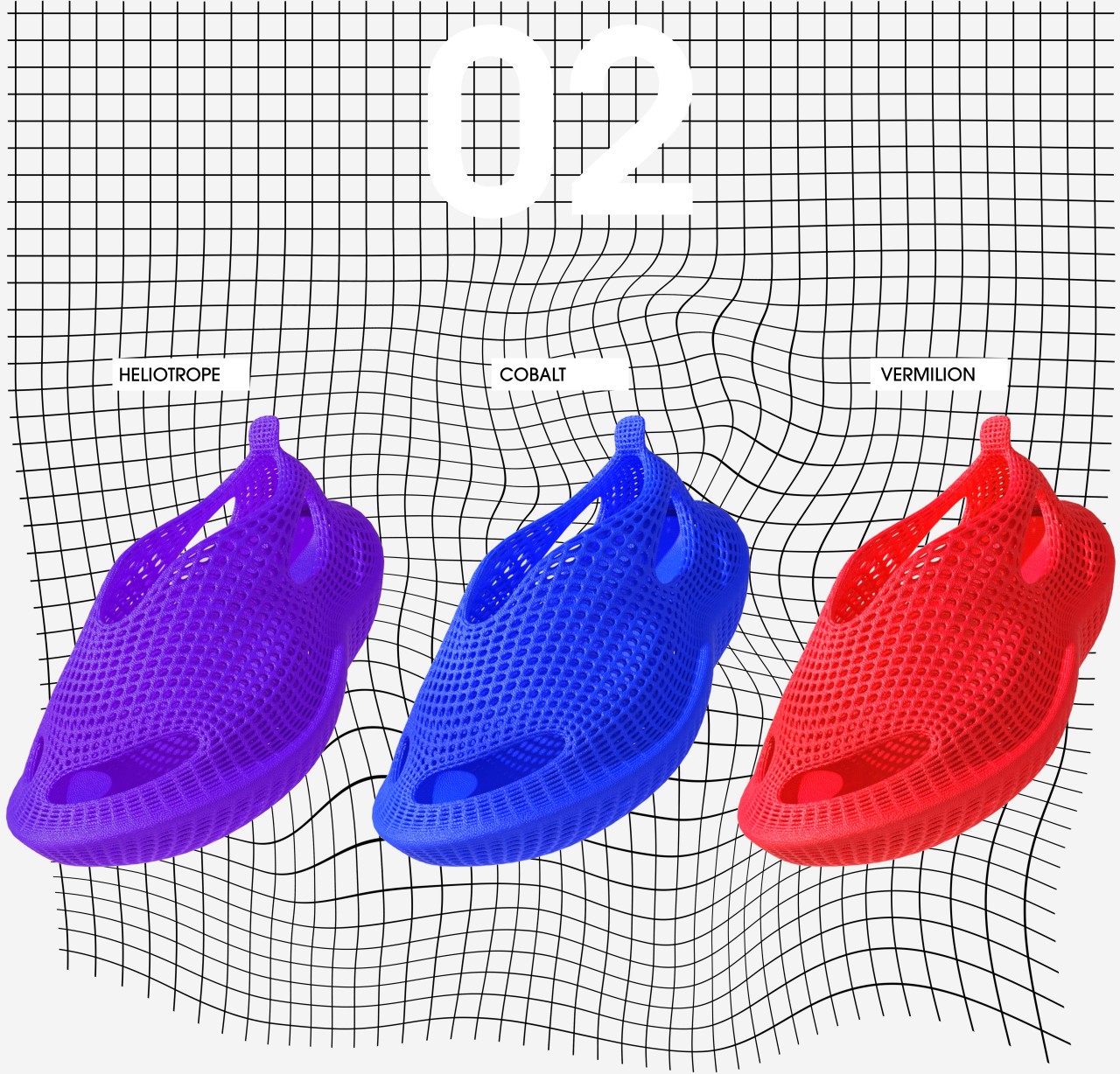

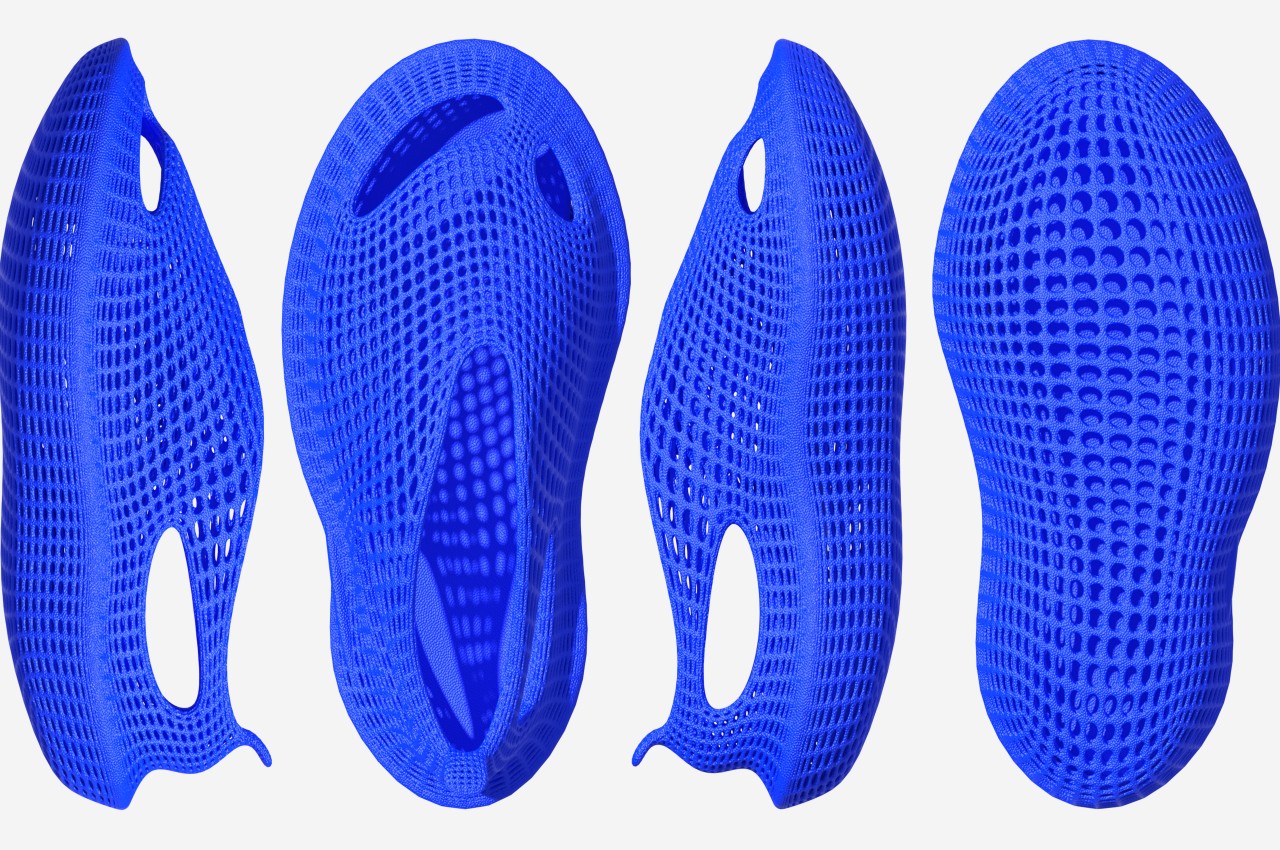

The result is a pair of shoes that look like the wireframe that you’d see in 3D modeling software, though with an even higher resolution and number of empty spaces. The design, however, takes its inspiration not from those digital artifacts but from nature itself. Repeating patterns, organic forms, and an almost chaotic composition all come together to create footwear that is both beautiful and intriguing.

This kind of design also pushes the envelope of what can be produced by 3D printers, particularly because of structural and material requirements. The complex mesh structure of the shoes requires an agile and flexible 3D printer, while elasticity and durability would need to be provided by unconventional materials that might not yet be available on these printers.

Whether EXPLR 02 can be a useful and practical footwear design, however, is still an open question. The myriad holes on the shoe’s surface provide better ventilation but also has less protection for the foot inside it. The structural integrity of such a design can also be in question since the thin intersecting lines could make it less durable under rugged conditions. Once resolved, though, it could open the doors to usable 3D-printed footwear, which could, in turn, unleash the floodgates of creativity in coming up with fresh shoe designs.