Formed from the dense carbon mesh and concrete cast, the Cube will comprise of two main components.

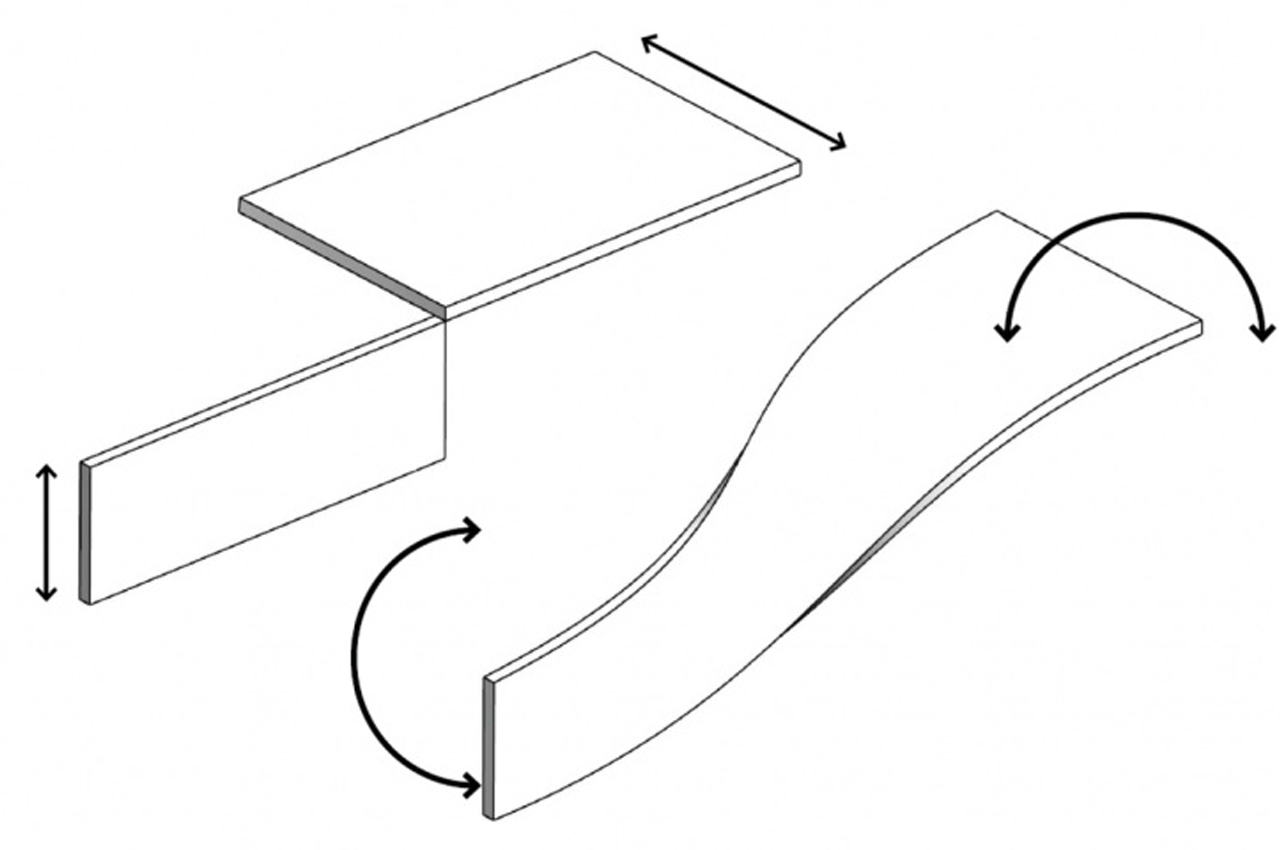

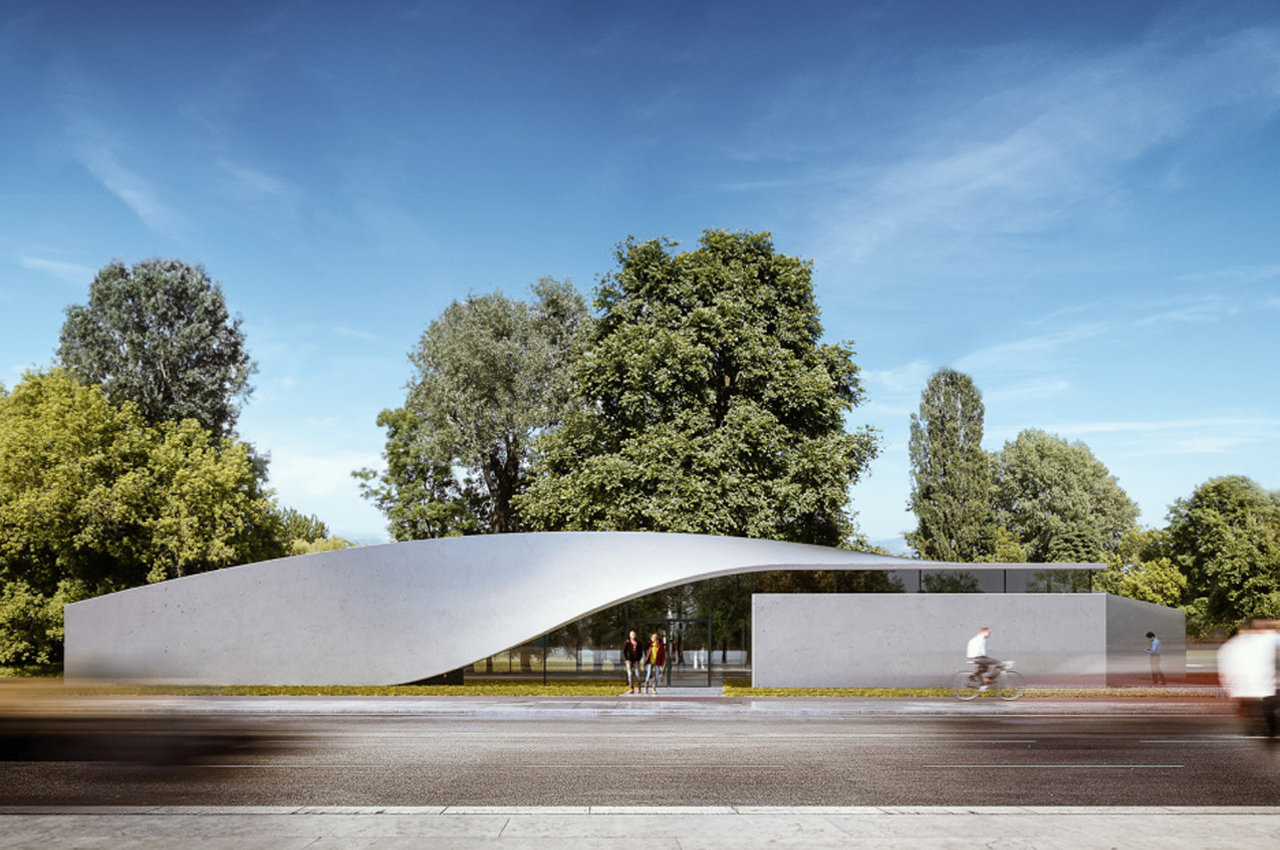

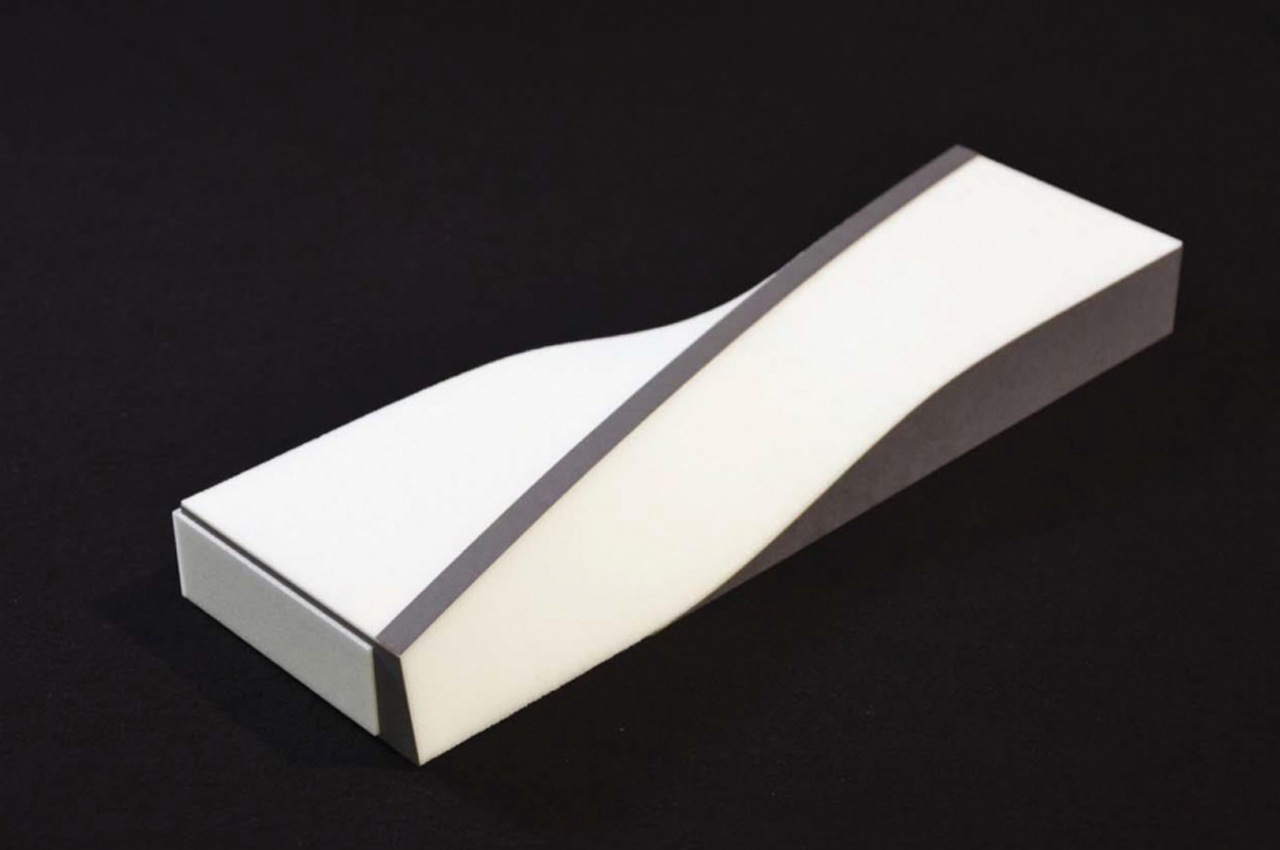

Henn, an architecture firm based in Germany, recently unveiled the concept for the world’s first building made from carbon-reinforced concrete in close collaboration with researchers at the Technical University of Dresden (TUD). The so-called Cube will primarily function as an exhibition space and research facility for the university’s students, and will also house a classroom and small kitchen. Formed from the dense carbon mesh and concrete cast, the Cube will comprise of two main components, a precast box that will make up the floor and walls, and a double-curved roof, twisted from the bendable carbon-reinforced concrete.

The Cube will function as a central hub for university students where they can gather for research and learning. Researchers from TUD have been researching the functionality of carbon-reinforced concrete since 1998. Now, in collaboration with Henn Architekten, the newly developed concrete building material can be put to the test. Carbon-reinforced concrete essentially replaces steel rebar with carbon fibers to maintain concrete’s industrial strength while reducing the amount of concrete used for construction.

Henn describes, “Carbon concrete could contribute to more flexible and resource-saving construction processes, and switching to carbon concrete could reduce the CO2 emissions from construction by up to 50 percent.” The Carbon Concrete Composite is developed through a process of thermal decomposition called pyrolysis that binds together carbon fibers to produce carbon fiber yarn, which creates a dense mesh that unites and strengthens the concrete. The removal of steel rebar makes carbon-reinforced concrete four times lighter than traditional concrete building material. Carbon-reinforced concrete also lasts longer since the carbon mesh is rust-proof and its technical makeup inherently evades the threat of oxidation. Inside, the Cube houses a single classroom, research facilities, an exhibition space, and a small kitchen.

The single unit of carbon concrete proves the versatility and malleability of the building material during the building’s development stages. “The benefit is that you can make the concrete much thinner while being able to carry heavy loads, so you can design completely different shapes. There are some research examples of super-thin concrete building components or benches or reinforcements. The aim is to get away from the huge amounts of concrete that are being used today.”

The Cube’s final form merges its ceilings and walls into a single unit, as Henn explains, “The design reinterprets the textile nature of carbon fibers through the fluid merging of ceiling and walls in a single form, suggesting a future architecture where environmentally conscious design is paired with formal freedom and radical rethinking of the most basic architectural elements. Wall and ceiling are no longer separate elements but functionally merge into one another as an organic continuum.” Ditching the rigidity of steel rebar for more versatile building material like carbon-reinforced concrete allows architects to design structures in new shapes and with fewer structural parameters. Additionally, the lightweight nature of carbon-reinforced concrete means less building material used and CO2 emissions released during construction.

Designer: Henn Architekten and the Technical University of Dresden