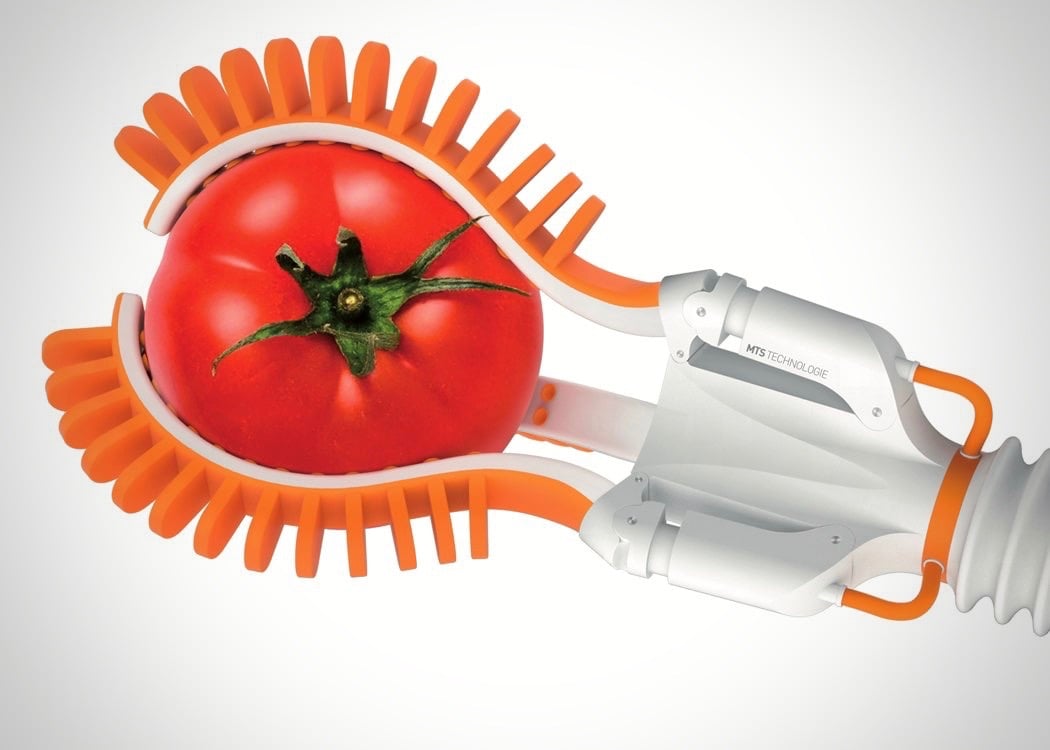

Component deformation… force transmission… nanotechnology… these are just a few fancy terms for describing this far-out twist on the robotic arm. Until now, gripper arms have only been composed of complex structures and hydraulic motors which are prone to complication. The Magnetic Transformation Structure reimagines the robot and uses an intelligent, unique and globally applicable principle to make things simpler and more precise.

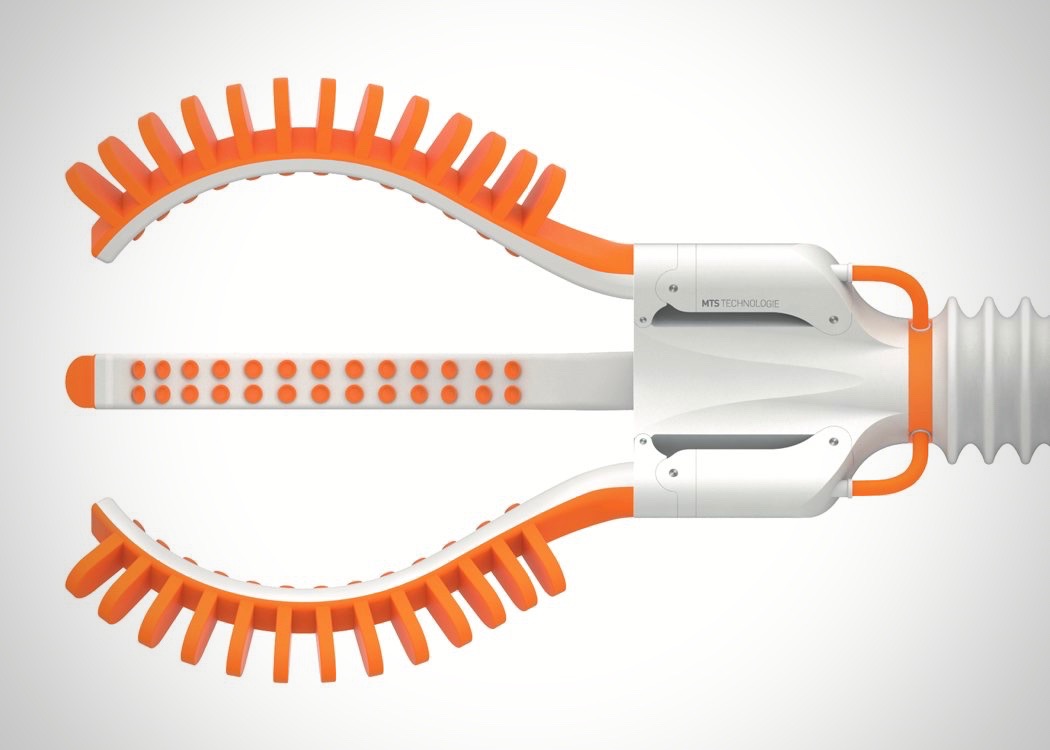

The principle of this structure begins with parallel sequential segments that are arranged on a flexible material. In the center of each segment is a metal core, which allows a magnetic field to be specifically generated via electrical current in each individual segment. The adjacent segments that are magnetized to have like magnetic poles will repel each other. With unlike magnetic poles, they attract each other. Since the segments are bound to the flexible plate only at the base, the magnetic forces generate a torque that naturally bends the plate.

The result is more economical production, faster reaction times as a result of targeted force transmission, uncomplicated deformation of mechanical components and more flexibility than the hydraulic systems this tech aims to replace.

Designer: Emami Design