From the conceptualization to the actual production, the Differential Growth Vases hardly had any significant human intervention. The vase shape was determined by a differential growth algorithm, while a 3D printer manufactured the vase. Although designer Tim Zarki orchestrated the project and came up with the very idea in the first place, the machines pretty much took over the execution of both the concept and fabrication phases, displaying two things – AI-based creativity, and the ability to have humans step away from creative roles with a fair amount of success.

Designer: Tim Zarki

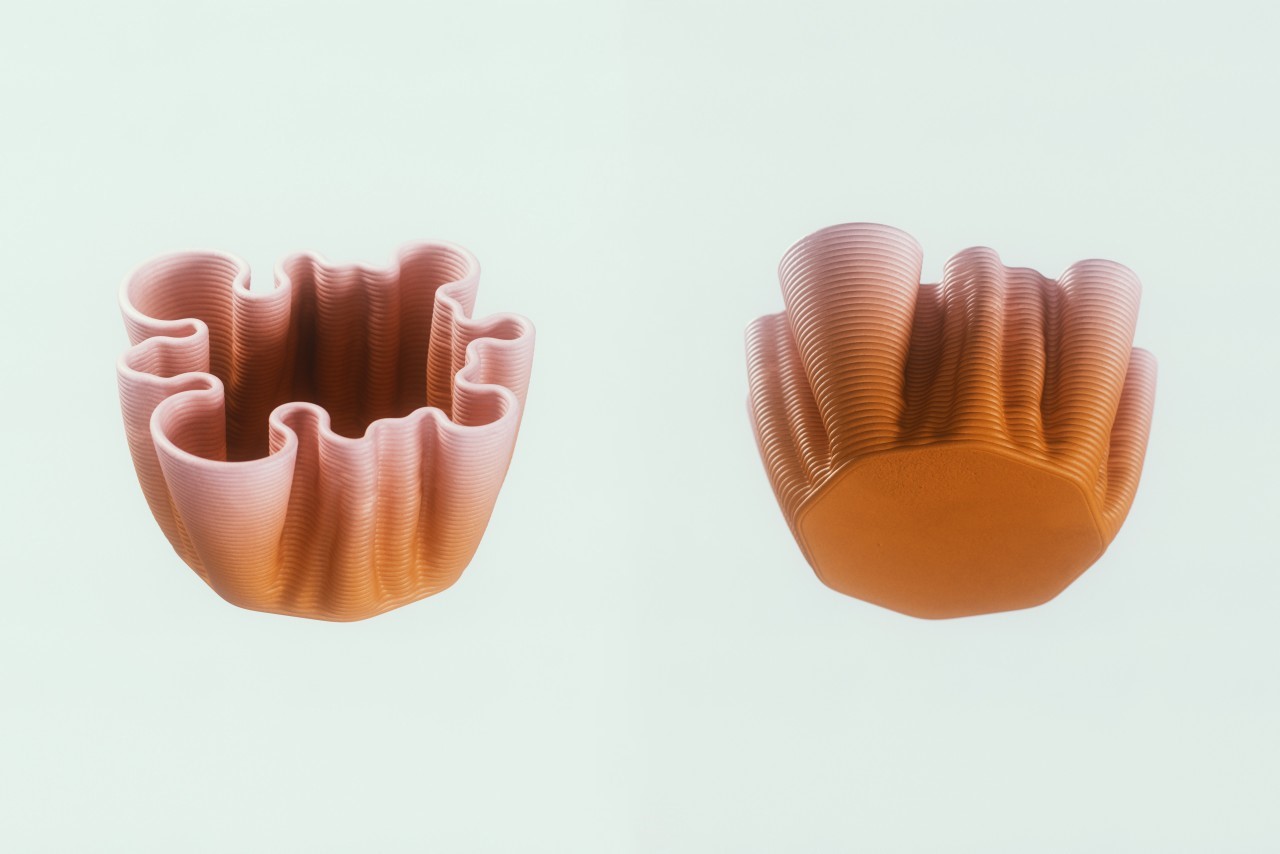

Differential growth might sound like a fancy term, but it’s a way of explaining how cells multiply. The process can be understood through a series of rules that are repeatedly applied to points in space (called nodes) connected into chains by lines (edges) to form paths. In short, the cells adopt a pattern (based on their DNA) and create within that particular pattern, resulting in growth that follows a template set by previous cells. You can see this in how plant branches grow, how cells expand, how rivers meander, etc. Zarki put the same sort of algorithm to the test with the vases, setting a base shape and having the algorithm expand it. The result is nothing like any pottery you’ll ever see…

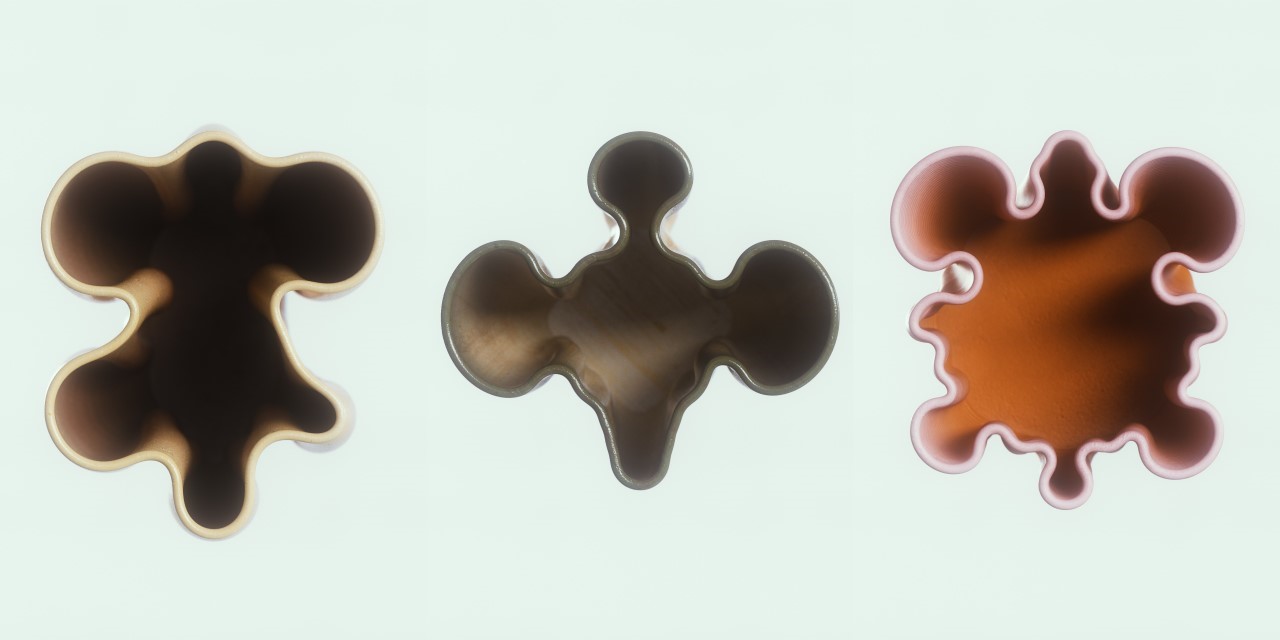

While most vases are created using a potter’s wheel, resulting in a rotationally symmetrical design, these vases have undulating designs created by the algorithm. The best way to understand how the algorithm works is to look at the shape of the base of the vase, and the final shape at the top. The vase’s vertical growth shows the transition between these two shapes, helping you understand how the algorithm works. There’s never a set final pattern, as the algorithm creates something new each time. This means each vase ends up looking unique. Zarki experimented with three overall designs, although the possibilities are quite literally endless, much like how no two plants grow the exact same way, or no two fingerprints look the same.

The final forms were then fed into a slicer software, that helps prepare them for 3D printing. The slicer creates a path that the printer’s nozzle has to follow, and once ready, the printer gets to work, slowly, but steadily printing the vase. As is evident, this entire process is nothing like the current conventional pottery methods, but with this project, Zarki hopes to challenge convention. By eliminating standard processes, and to quite an extent the human too, these vases show how oddly appealing a world would be to live in if AI designed more… obviously with humans playing a final role in determining whether the design is aesthetic or not!