3D printing has brought a lot of changes when it comes to designing products. It has made experimentation with various materials and prototyping these proposed designs easier and more efficient. We’re seeing a lot of concepts get past the initial product rendering stage just by utilizing various 3D printing techniques and tools that are now available and is constantly evolving.

Designer: Nils Sorger

The +/- Brace is one such concept for a pain relieving elbow brace that can be used when doing physical labor or any kind of sports that requires strenuous activity so you can minimize the risk of injury. It’s something that can be created and customized using an app. choosing your size, form, structure, and padding. The final product you created can then be fabricated on your own, ordered through the maker community, or ordered through the creator’s app platform.

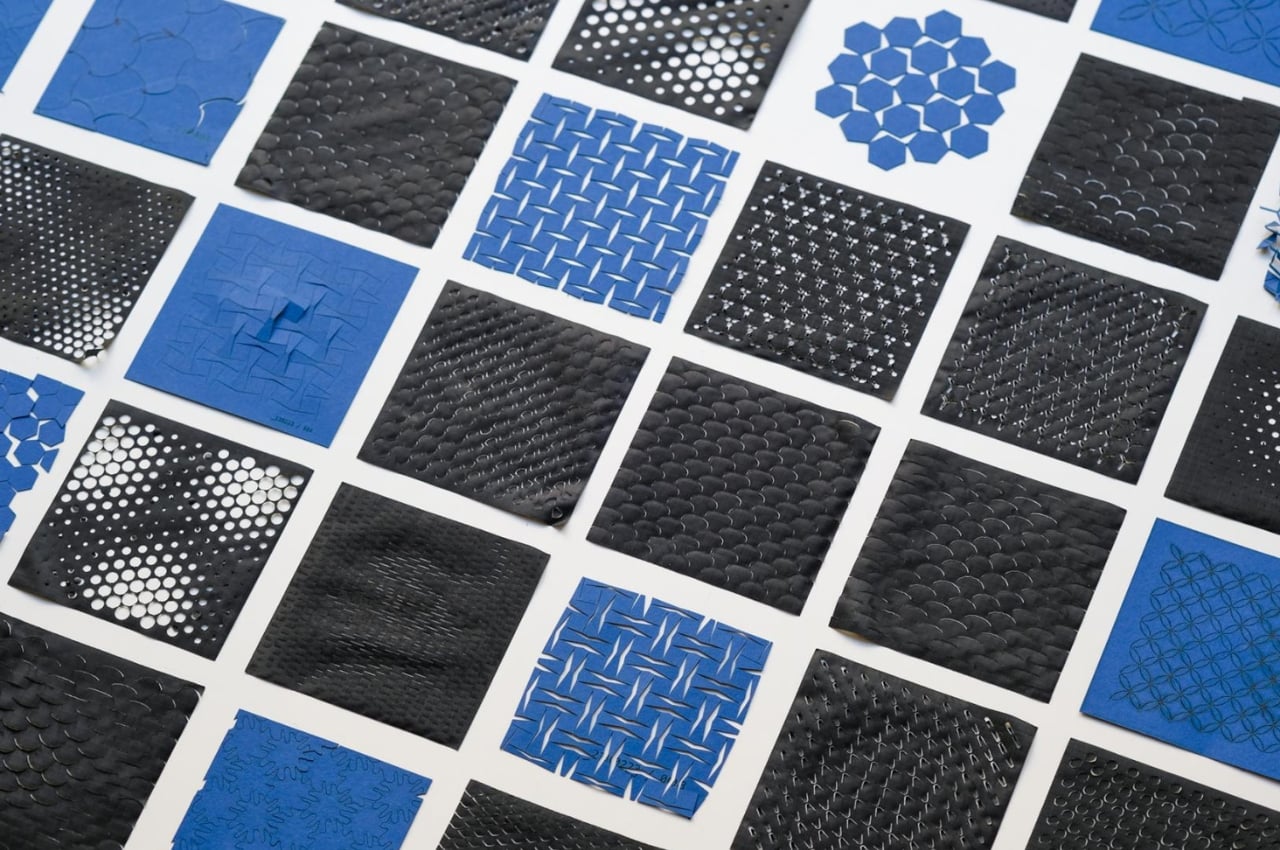

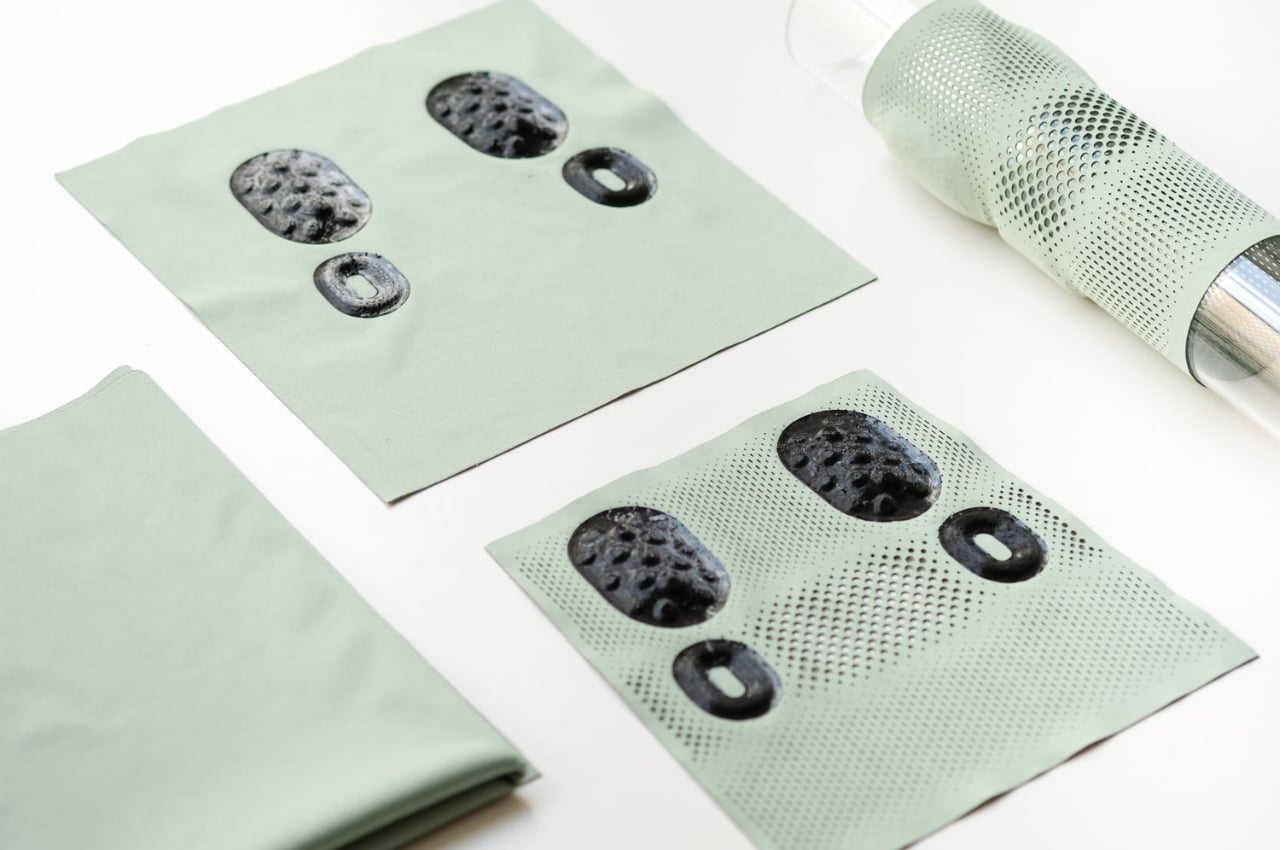

The 3D printing and laser cutting machine is called Grasshopper with a custom built script so body measurements inputted can be used to generate the data output. They used various iterations to find the optimal pattern for the brace and ended up with the 4-way stretch softshell fabric which is made up of 49% Polyester, 30% Polyamide, 12% Polyurethane, and 9% Elasthan. This is the best one for breathability and flexibility as well as a comfortable and flexible fit so you can still do all the activities you need to do. For the additive, they also tested several FDM-printed pads and ended up with something that is like foam or gel.

After much prototyping, the +/- Brace ended up with an aesthetic that seems like a combination of a Bluetooth speaker and a honeycomb packaging. It looks pretty flexible and comfortable, which are important characteristics of this kind of product so the user will not really feel like the brace is hindering their movement. All thanks to the improvement and enhancement of the 3D printed fabric-based manufacturing plus open source process, they were able to conceptualize and actually prototype this kind of individualized brace that shouldn’t break the bank.