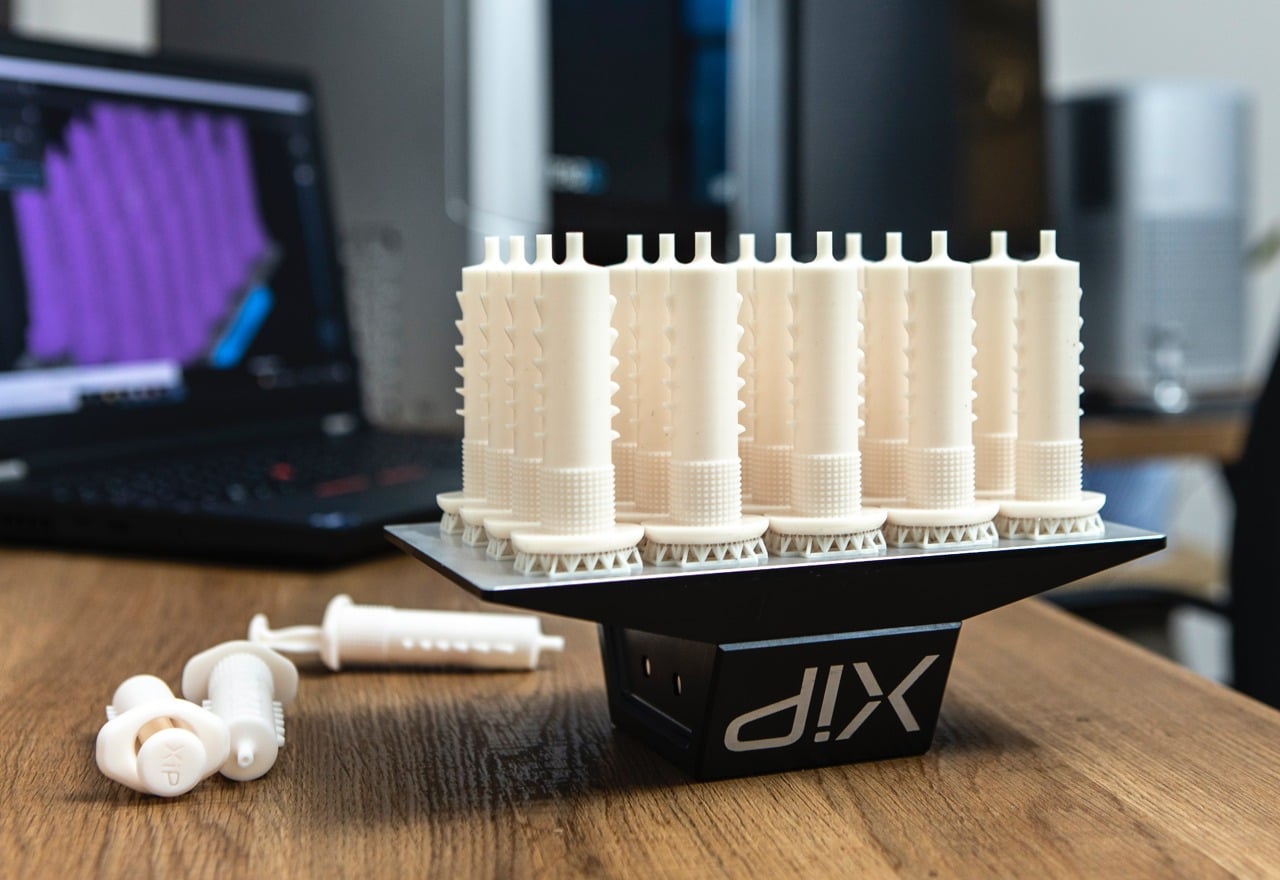

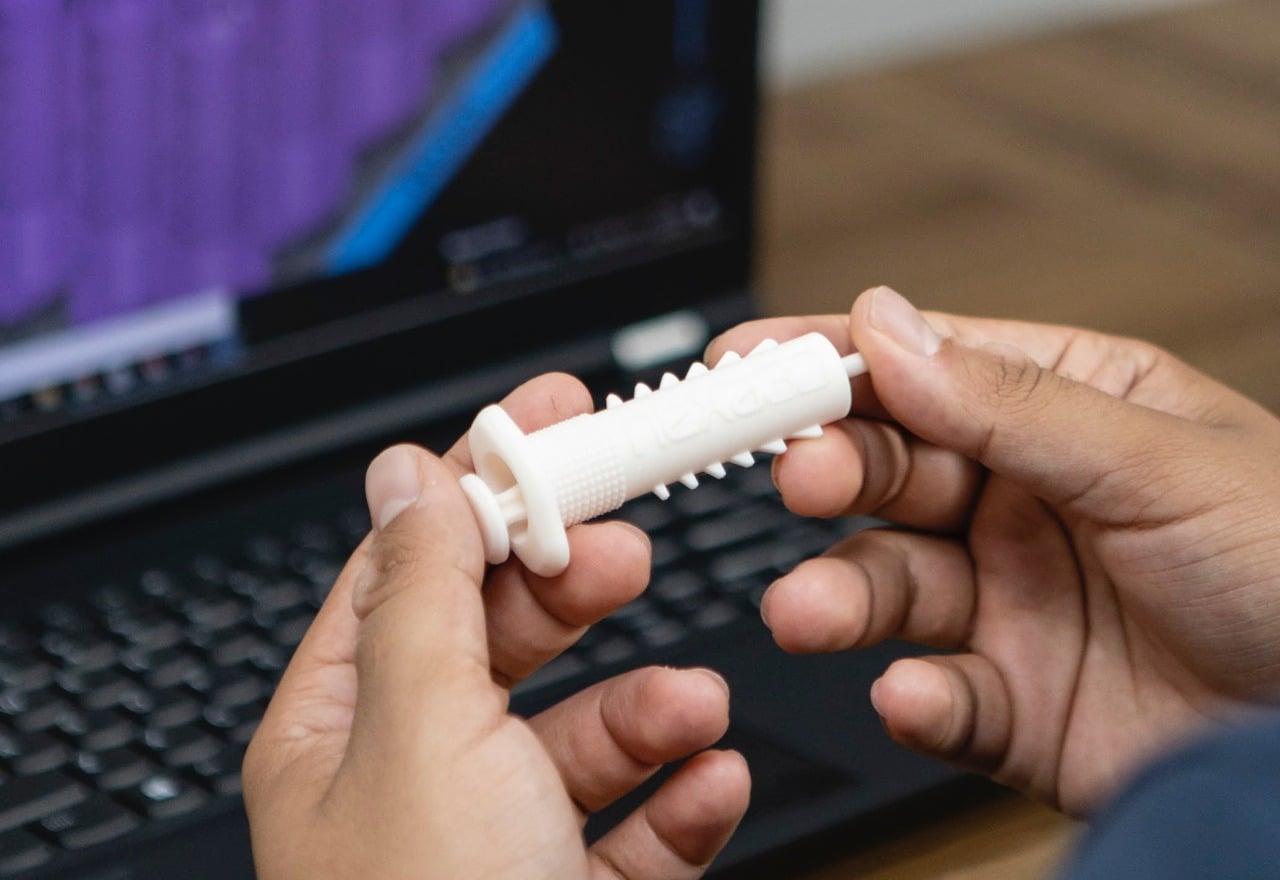

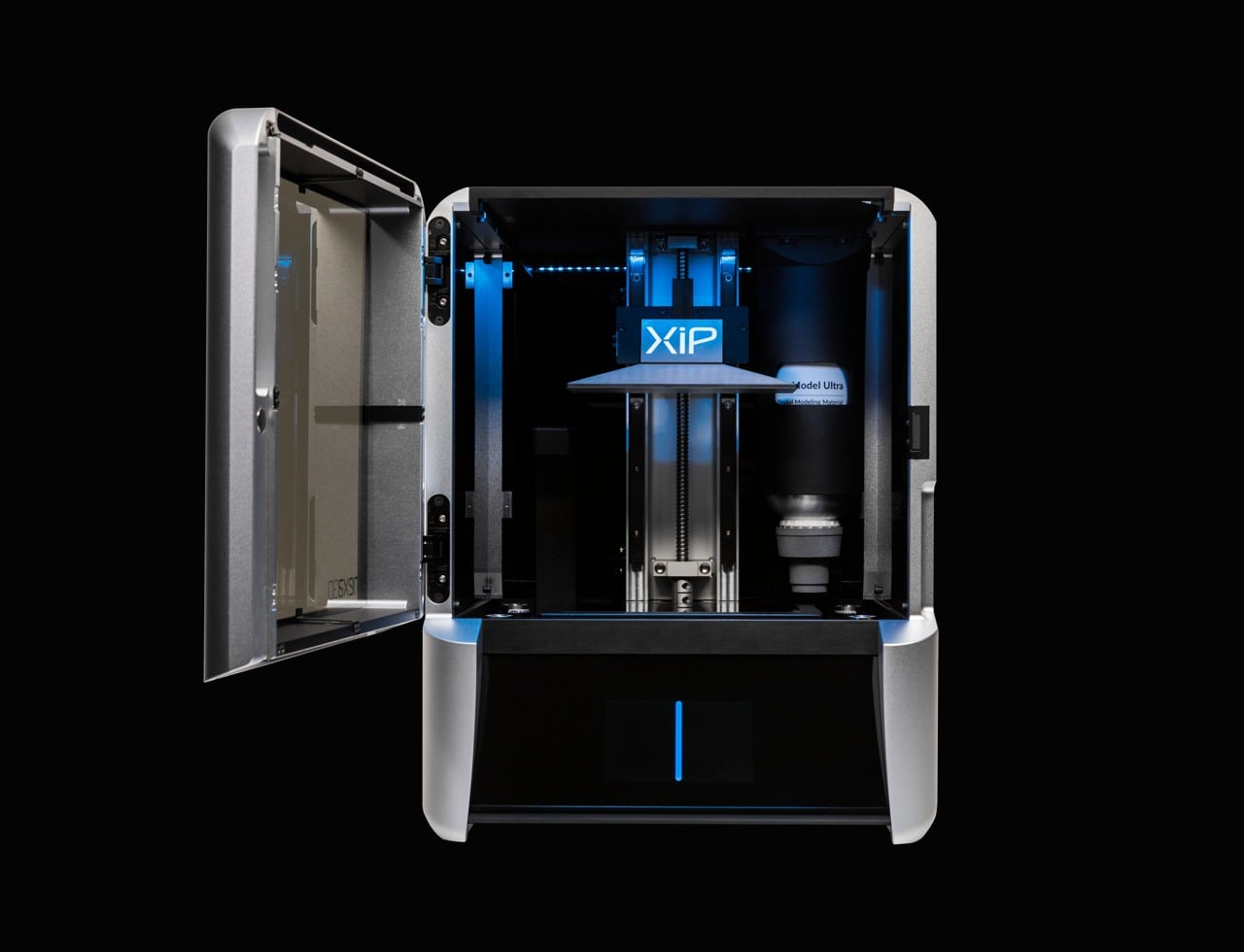

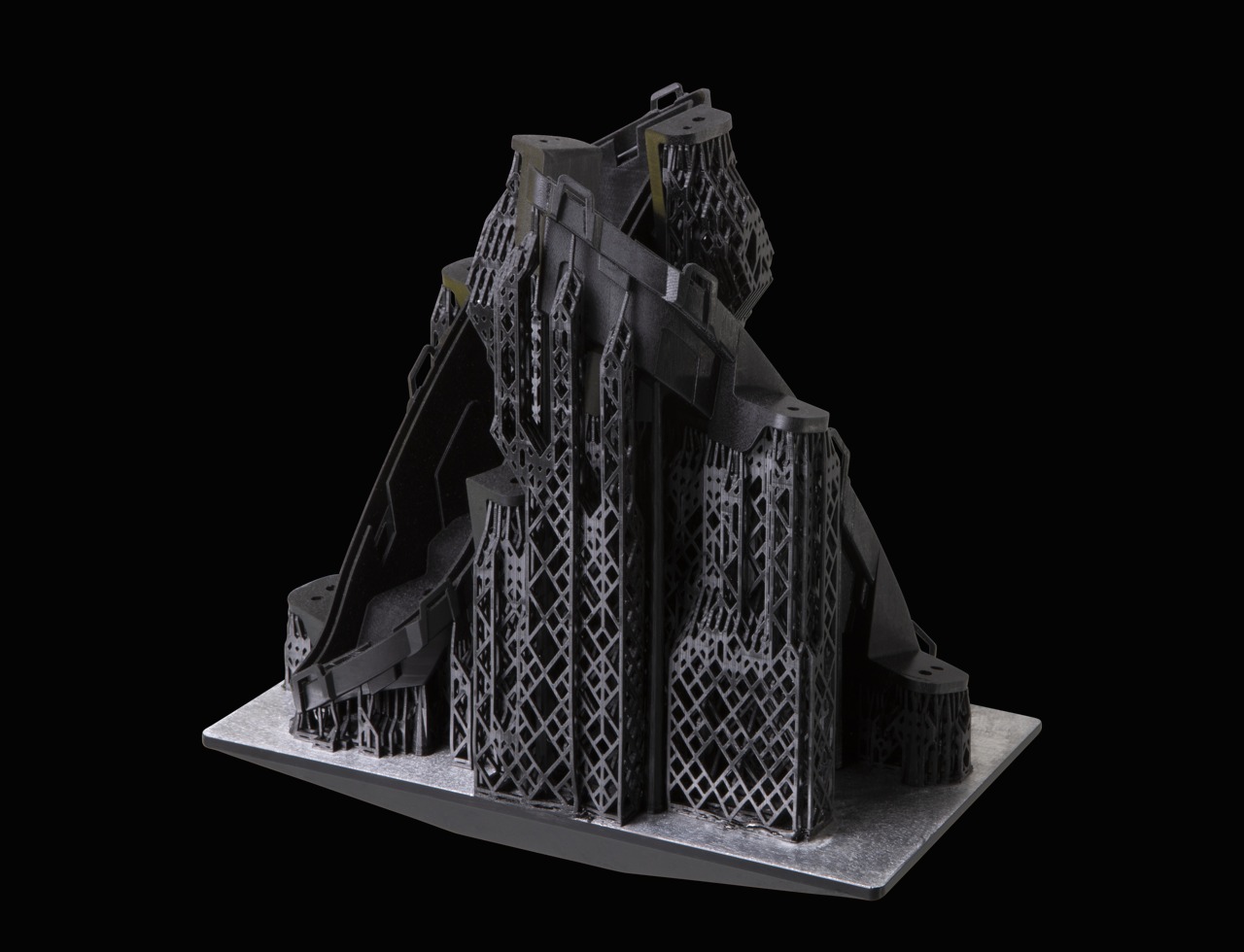

Armed with a 4.8L build volume and industrial-grade 9.3″ 4K Monochrome LCD that gives you incredibly crisp and fine details on your prints, XiP is an advanced ultrafast resin 3D printer that brings professional-grade 3D printing to designers and engineers, offering speeds 6x faster than SLA printers and more than 10x faster than filament 3D printers. XiP is built for professional designers and engineers, and packs Nexa3D’S industrial LSPc technology into a compact desktop package measuring 16.5 inches wide, 14 inches deep, and 21 inches tall. LSPc (Lubricant Sublayer Photocuring) was developed for Nexa’s NXE 400Pro industrial 3D printer and is a combination of industrial light engine and proprietary vat / membrane that allows for ultrafast 3D printing and exceedingly complex geometries without the need for excessive, hard-to-remove supports.

Designers: Nexa3D and Mocu Design

Use Coupon Code “BLACKFRIDAY500” to get $500 off!

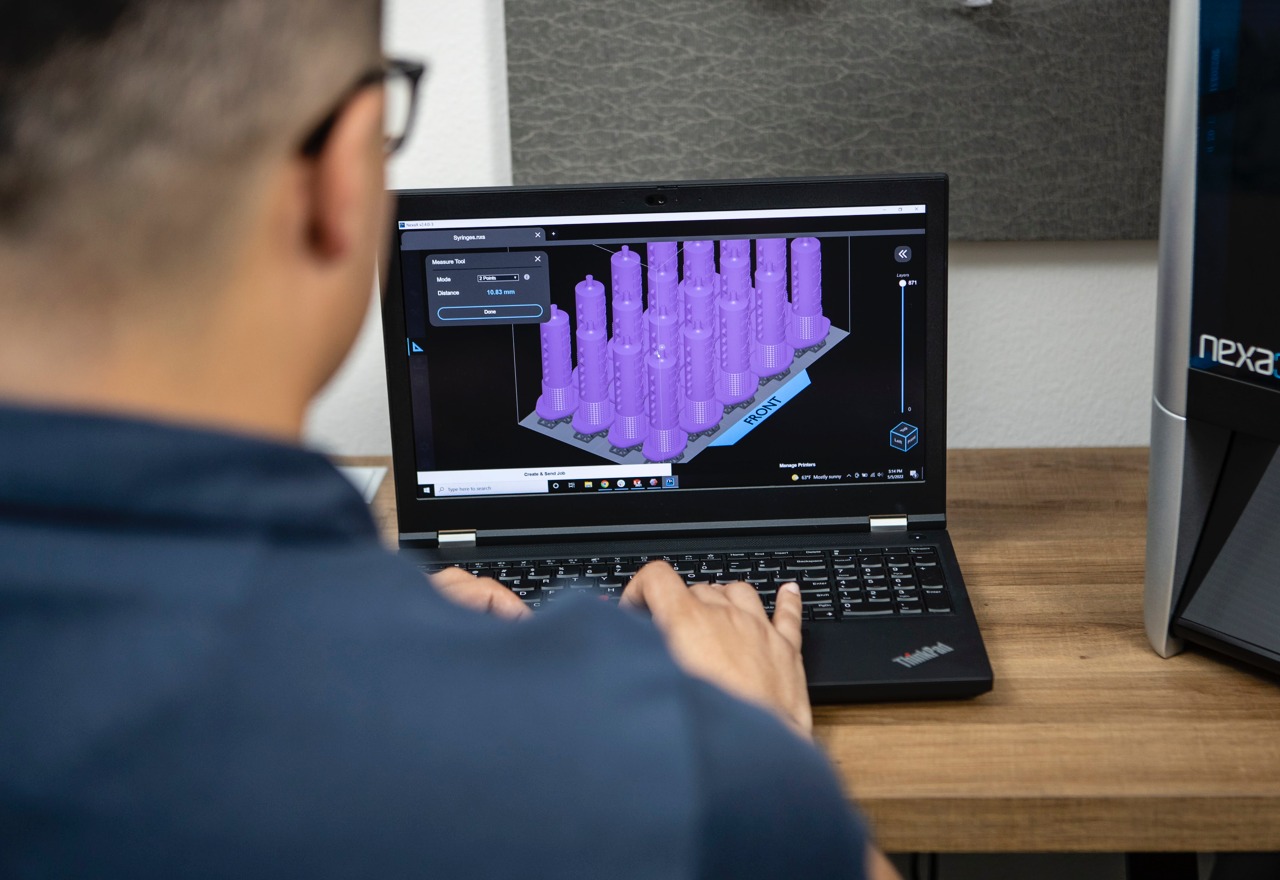

A metric of any good resin printer is its light engine, but also its build quality. The XiP Desktop 3D Printer shows off its sturdy billet aluminum enclosure, complete with rigid parallel linear rails and a precision ball screw Z-axis platform that moves the build plate upwards as the resin cures. The resin sits in a large 4.8-liter vat with Nexa3D’s proprietary Everlast-2 membrane, right above a 9.3-inch 4K LCD with a 52 µm pixel size, giving you incredibly fine details. The build plate’s high-precision drivetrain also has it move as little as 0.002 inches at a time, giving you a 0.05mm layer thickness (which is fairly impressive for a 3D printer).

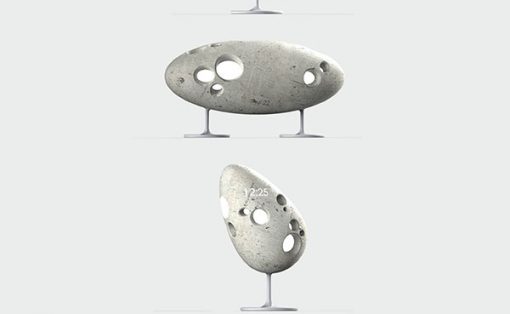

XiP’s highly precise printing capabilities are only further enhanced by its open materials platform, which allows XiP to work with a wide variety of resins. XiP’s makers, Nexa3D, have a growing network of material providers, the likes of Henkel, BASF, and Keystone, and the company develops its own in-house resins to aid various applications, including standard resins for rapid prototyping, model and splint resins for dentistry, biocompatible resins for medical applications, and even high modulus, durable, or elastomeric resins for specialized industrial use. The 20+ validated resins for XiP include three high-performance analogs of the thermoplastics ABS, PP, and PEEK. Each resin is packaged 1-liter recyclable aluminum smart cartridges that auto-fill resin throughout the print.

As advanced as its features and capabilities sound, XiP is first and foremost a user-friendly device. It comes with an easy-to-assemble internal architecture to let you load the resin of your choice and a 5.5-inch touchscreen display that guides you through the printing stages. XiP supports inputs using ethernet, USB, or even over WiFi, letting you send print commands even over your home network so you don’t need to have the printer in the same room as your computer. To maintain the integrity and quality of each print, XiP houses its own air purifier and filter that traps any dust that may otherwise get into the machine. Once your prints are ready, XiP’s wash and cure station lets you easily clean up your print with minimal mess.

Use Coupon Code “BLACKFRIDAY500” to get $500 off!