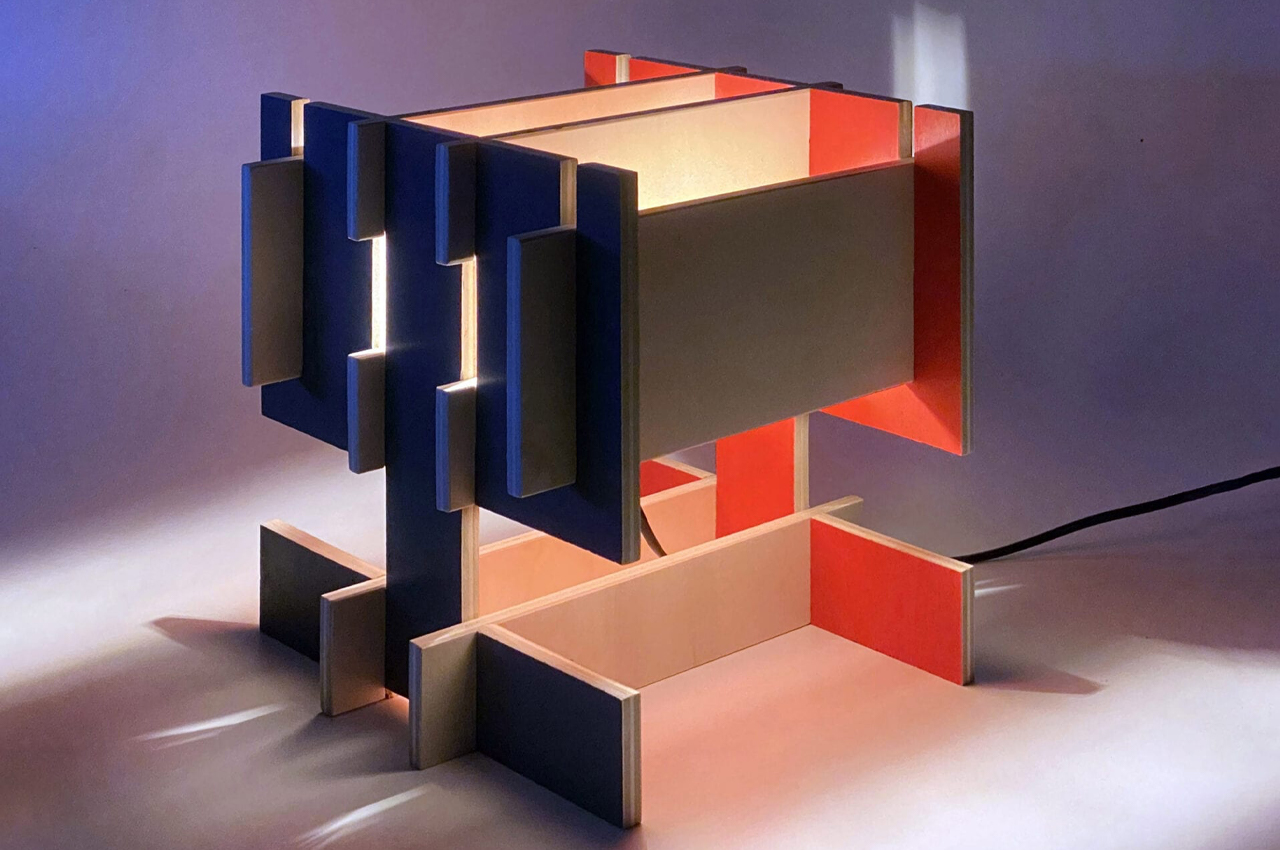

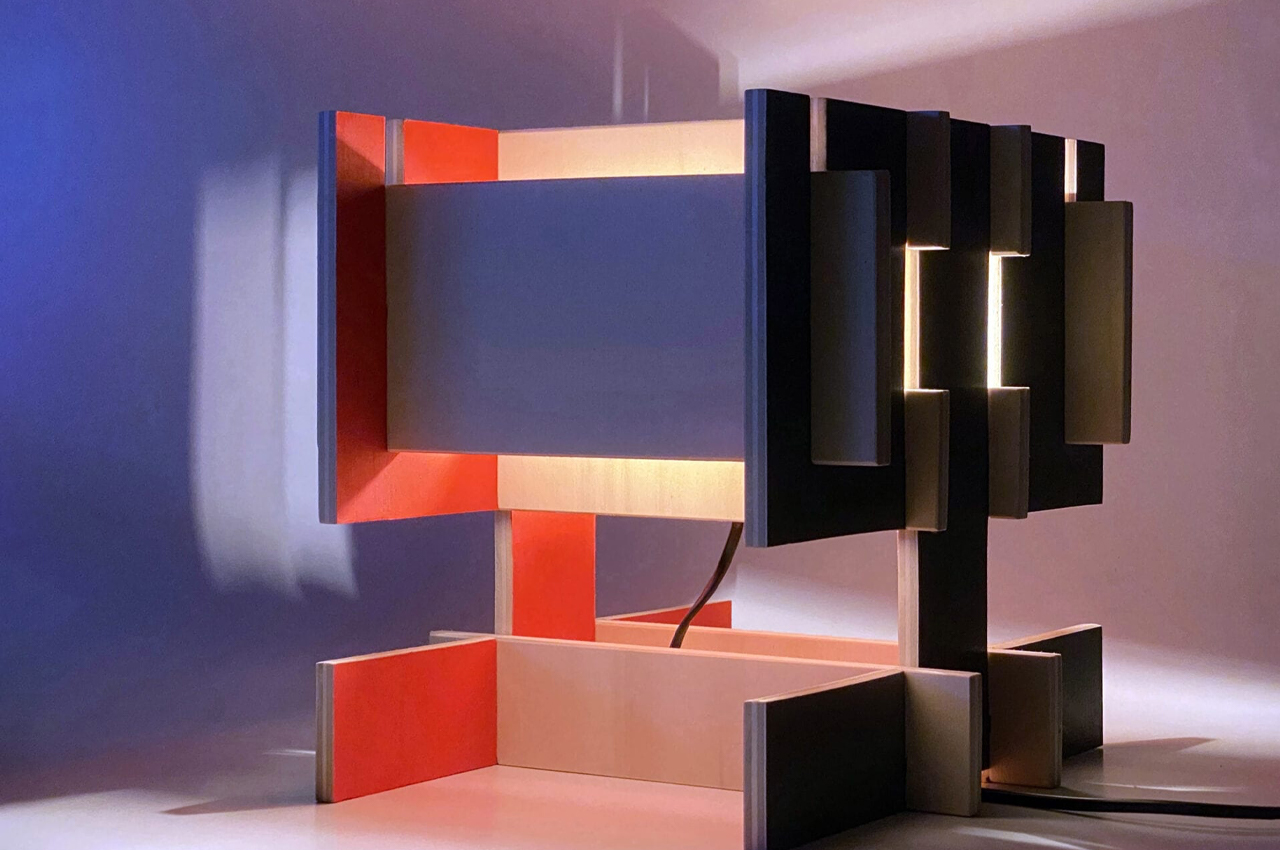

The BN! is a modular, customizable table lamp that’s constructed from CNC-milling techniques to ensure precise and interchangeable assembly.

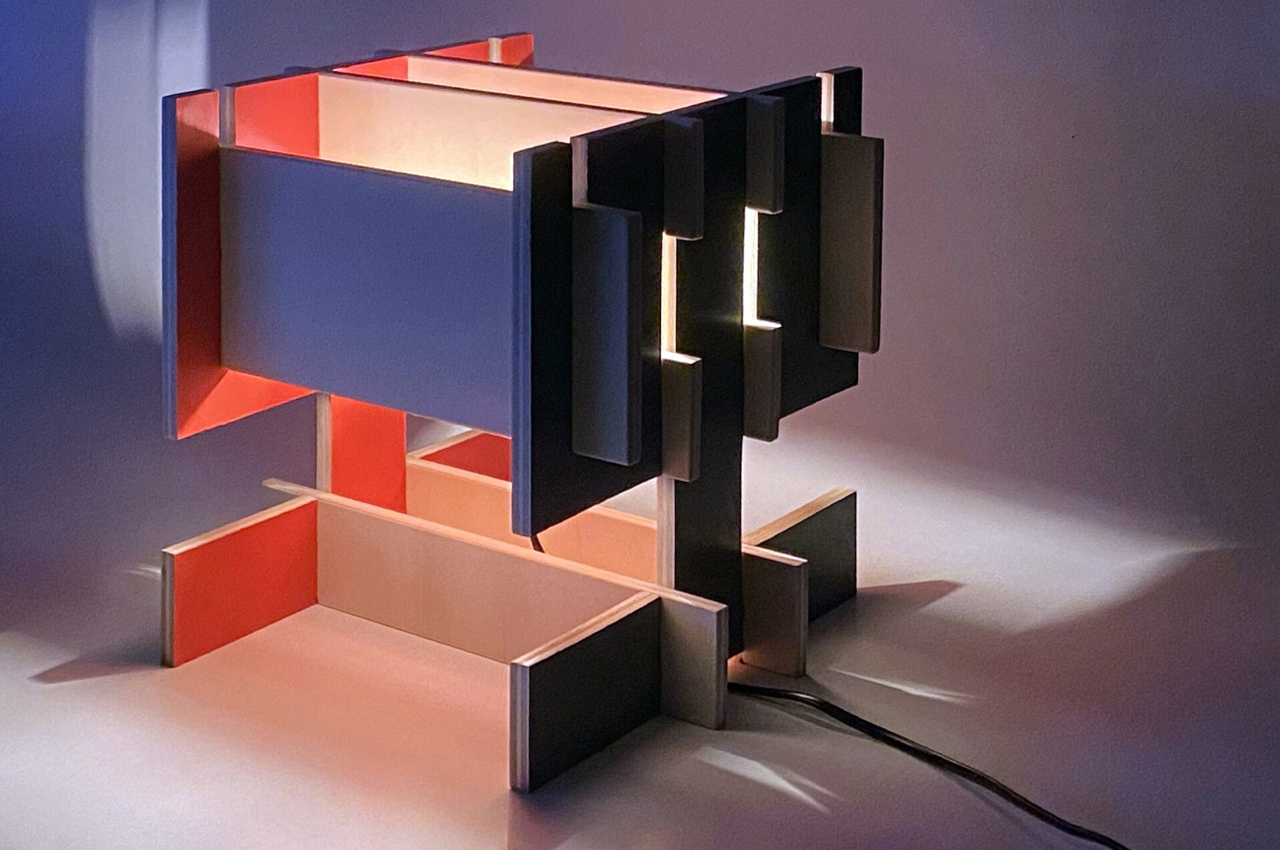

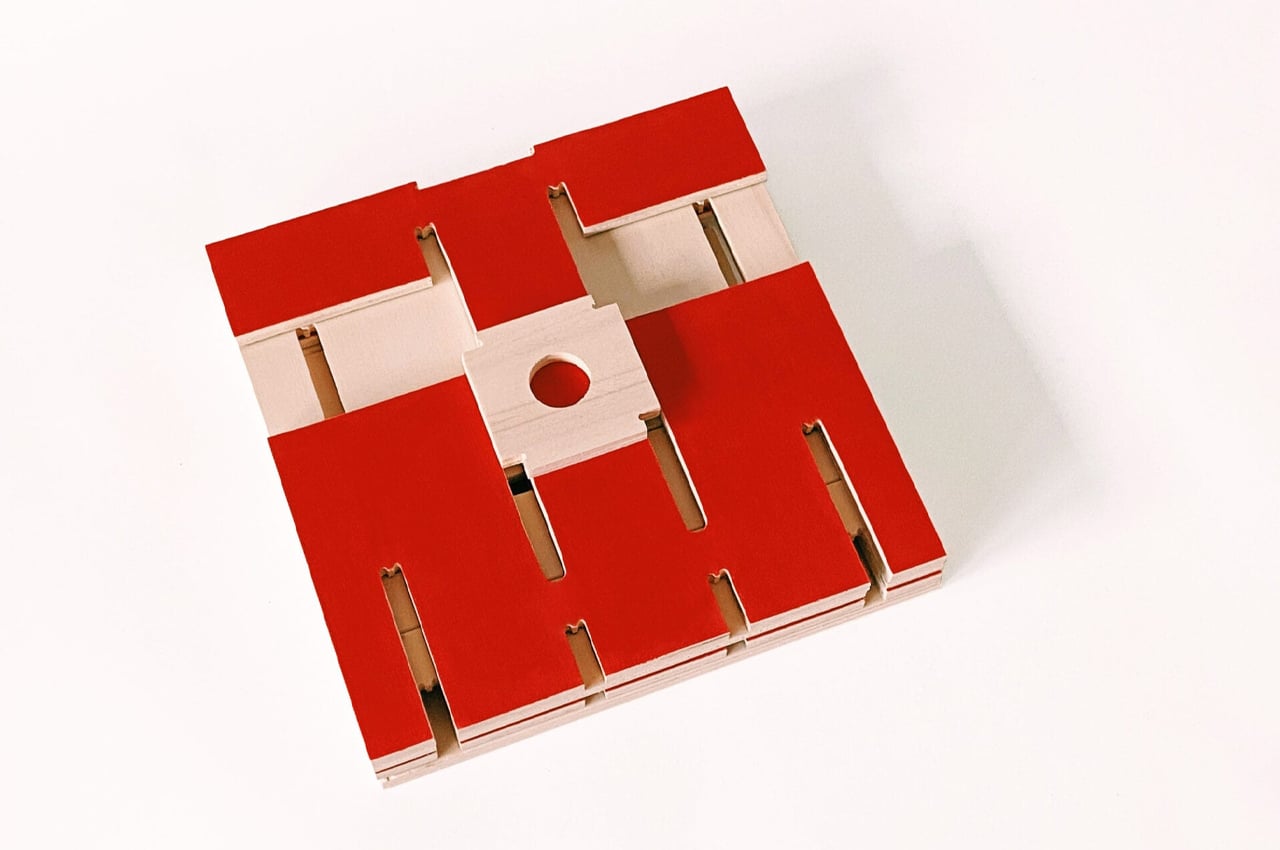

Timber toys, like Jenga and burr puzzles, depend on precise fittings and even edges to fulfill their purpose. Much like those timber toys, wooden product designs that are CNC-milled maintain a symmetrical and unified structure to ensure seamless assembly and operation. CNC-milling also allows designers to keep the number of building materials to a minimum.

Designer: Baliza Norte

From wooden figurines to timber homes, CNC-milling is trusted as the means to format components and cut them down to their most precise angle. The BN! Lamp designed by Baliza Norte, an architecture and interior design project, is constructed using CNC-milling techniques for an assembly process that doesn’t require any hardware or tools.

BN!, a lamp named after the company that designed it, is a tabletop lamp constructed from sheets of plywood that were pre-fitted to fit into each other without the need for extra hardware or tools. Delivered in a flatpack design, when disassembled, BN! Lamp perfectly fits in a 28 x 28 cm square and can easily be packed for shipping or transporting.

Using modern CNC technologies, each component of BN! Lamp “is intended to be a playful object which can be easily assembled or disassembled, it subtlety evokes a timber toy.” Since each module of the BN! Lamp is fitted for precision, each one can be replaced when necessary. The modular and interchangeable configuration of BN! Lamp also allows users to choose the brown color scheme, giving the lamp an air of bespoke appeal.