The advent of electronics had ushered in the third Industrial Design revolution but we are slowly moving beyond the realm of tangible, screen-based interactions to discover multiple new possibilities. These discoveries are the cause for which, the World Economic Forum and many other leading research agencies are deeming the upcoming trends as the fourth Industrial Revolution. In the article below, Paul Hobcraft explains what exactly does this fourth revolution entail and how will it affect the industries and hence, the world around us.

Recruiting a designer? Post a job with us to source the best talent for your requirement.

Looking to switch over to a freelance career? Check out YD Job Board to work with some of the best design companies in the world!

There are twin forces at work, feeding off each other. We are facing greater disruption and an increasing innovation pace. These are constantly combining, relentlessly adding a new shape to our future. We are actually caught up in a very revolutionary period.

The days of simple product innovation are dwindling. It is through the fourth industrial revolution (also known as Industry 4.0), currently being undertaken, that technology, talent, and new innovation ecosystems are emerging – building greater complexity into our final innovation offerings. Intelligent automation and technology are fuelling this new industrial revolution. And this unprecedented, exponential pace of change is increasingly reliant on collaborative platforms to realize the result: more radical innovations.

Innovators struggle to manage in a new way

Organizations everywhere are facing mounting pressure to transform – to shift from product-centric business models to new models focused on creating and capturing different sources of new value. As a result, innovation is becoming more complex.

At the heart of this transformation is the fourth industrial revolution. Here, manufacturing is fast becoming the digital manufacturing enterprise (DME). The DME is designed to increase response rate and manage in more efficient, connected, and effective ways. There is this growing recognition that everything needs to be connected to bring a different perspective to any global value chain –one of being far more responsive and bringing manufacturing closer to the customer need.

How does your organization feel about our digitally connected world? We are all becoming more connected in the way we work, collaborate, and manage. Organizations are attempting to “fuse” different technologies to manage the existing physical world differently and are preparing themselves for the interplay between the physical and virtual world – one where this “connecting up” is promising to bring us. The ongoing investment in IT infrastructure is drawing in investments. It is changing the nature of where we will look for innovation outcomes in the future.

The fourth industrial revolution is one where we are gaining new knowledge and understanding. It is offering a very different potential for constructing new business models, products, services, and societal solutions. Many manufacturers are still in the early stages of this fourth revolution, but you have this sense of feeling that we are continuing to disrupt everything we know.

Welcome to the 4th industrial revolution

Wherever we turn in the manufacturing world, the technological revolution immerses us. The scale, scope, and complexity are things we’ve certainly never experienced. It is exposing us to exponential technologies. But what does that mean?

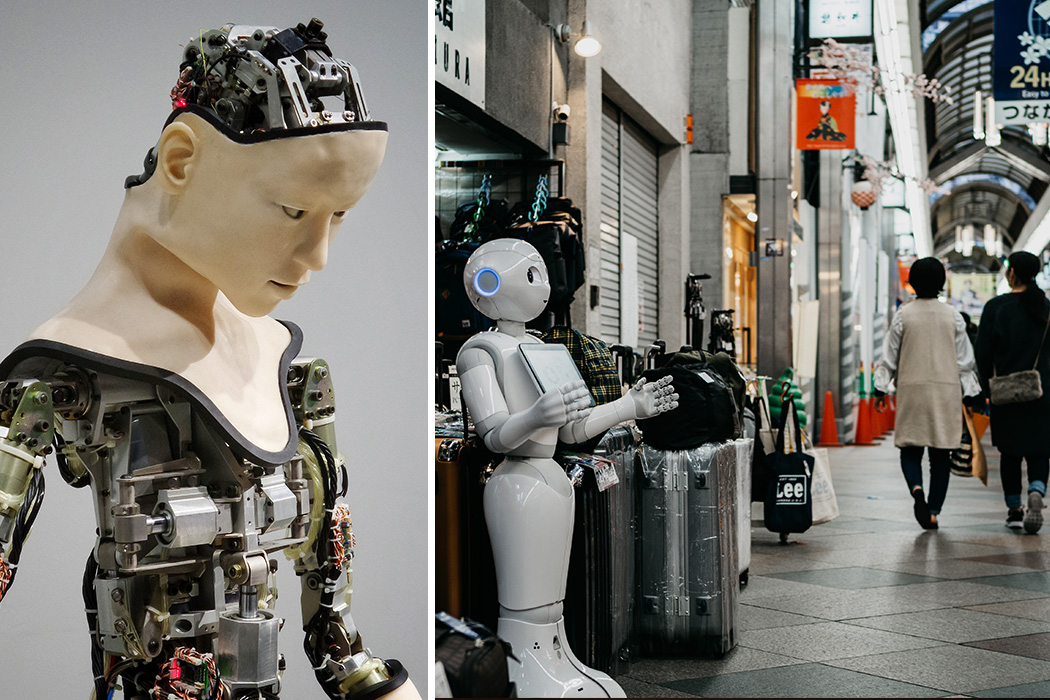

We seem caught up in such levels of velocity, scope, and systems impact – it is seemingly exponential, occurring at faster rates of change. Companies are radically overhauling entire systems of production, management, and governance on a constant basis of change. We have unprecedented processing power, storage capacity, and access to various avenues of knowledge. These are being combined with emerging technology in fields such as artificial intelligence, robotics, 3D printing, nanotechnology, biotechnology, material science, and quantum computing. It is creating fresh challenges and opportunities within innovation. Are we equipping ourselves to explore these?

Of course, we have faced industrial revolutions before. But, being caught up in one tends to leave us often conflicted. The first industrial revolution was based on water and steam to mechanize production. The second revolution was the use of electric power that led to the creation of mass production. Then we had the third revolution, where electronics and information technology started to deliver automated production. This fourth one builds on the third. It is the digital revolution where we are witnessing a fusion of technologies that seem to be blurring the lines between those past established borders to open up different meanings and business potential. It is truly exponential.

Confronted in multiple ways

We are looking increasingly to our engineers, designers, and scientists to unlock these new knowledge flows that bring us whole new areas of technological-based innovation. Product innovation is continually giving way to new concepts that have technology built into them. Our innovation has become increasingly complex, connected, and contextual.

Our industry value chains are being radically redesigned to accommodate “connected worlds” being more reliant on “everything” being digital. This is giving us new options for adapting quality to differently defined market needs. We are learning to respond digitally, in more dramatic and dynamic ways, to reflect pricing opportunity on increasingly opportunity marketing, so as we can appeal to wider sets of audiences or push our offerings out to explore different market potentials.

As we continue to design manufacturing to be fully connected-up, we can adjust faster, scale differently, and deliver quantities to varying cycles of demand, closer to the need of the day and more appealing to the customers. Our innovation scope changes with these new dynamics.

Today, we see a different spectrum of choice. We can order personalized clothes online that reflect the latest fashion, seen only days before. Manufacturing and delivery are taking days and not months to be available in-store or delivered to your door. We can design our own shoes. We can build complete vacation packages, designing our travel to meet our specific needs and budget. More and more, we want tailored experiences or solutions that fit our design need, not just “items” sitting on the shelf.

Mass production has given way to tailored design. We can track our orders, and we can engage directly with those that can deliver to our specific needs. Our engagement and growing relationship with customer service, our needs, and the organization’s service and response are all changing. All provide innovation opportunity to exploit.

Manufacturing is in a massive transformation

Manufacturing has progressively formed around cyber-physical product systems (CPPS) that are merging our real and virtual worlds into a seamless one. Software is optimizing every process and task, whether performed by humans or machines. These are ongoing online networks of machines connected in similar ways to our social networks that are linked through technology and digital infrastructures. Everything has become “smart.”

The revolution underway is connecting all the parts: the “internet of things” (IoT), of data, of services, and of people. We are very much still in the middle of this revolution, but it is where innovation will greatly benefit as this connecting-up continues.

We are constantly seeing progress occurring all around us. For example, we’re now more dependent on cloud processing and data storage than ever before. We are recognizing the value of having digital twins to simulate our manufacturing environment. We are designing software solutions specifically to simulate different scenarios, mirroring our real time to test options and optimize different set-ups, to reflect demand.

Our manufacturing plants are becoming far more integrated – virtually integrated. We are building industry 4.0 open standards so increasingly we can connect across manufacturing ecosystems even more, so as to reduce disruption or provide greater flexibility. We are exploring data analytics for learning and predicting, and this is placing a greater emphasis on collaboration, experimentation, exploration, and coordination from all this connecting-up.

Consequences of the 4th industrial revolution

We must reflect on all these direct consequences of the fourth industrial revolution. Where technology has combined with the physical to raise our customer expectations even further, it has given us different product enhancements that fit with our lives, one where we can contribute and collaborate more.

The customer is increasingly at the epicenter of the economy. The products and services are enhanced through the digital capabilities that boost their value and worth. New materials are making our assets more durable and resilient, and data and analytics provide valuable feedback needed to build even better services and performance for the future. All this connecting and reacting is requiring new forms of collaboration, and we are seeing new types of organizations emerging. They are far more dependent on platforms and ecosystems. Innovation is the unlocking mechanism.

We are required to alter our understanding of Innovation due to this 4th revolution

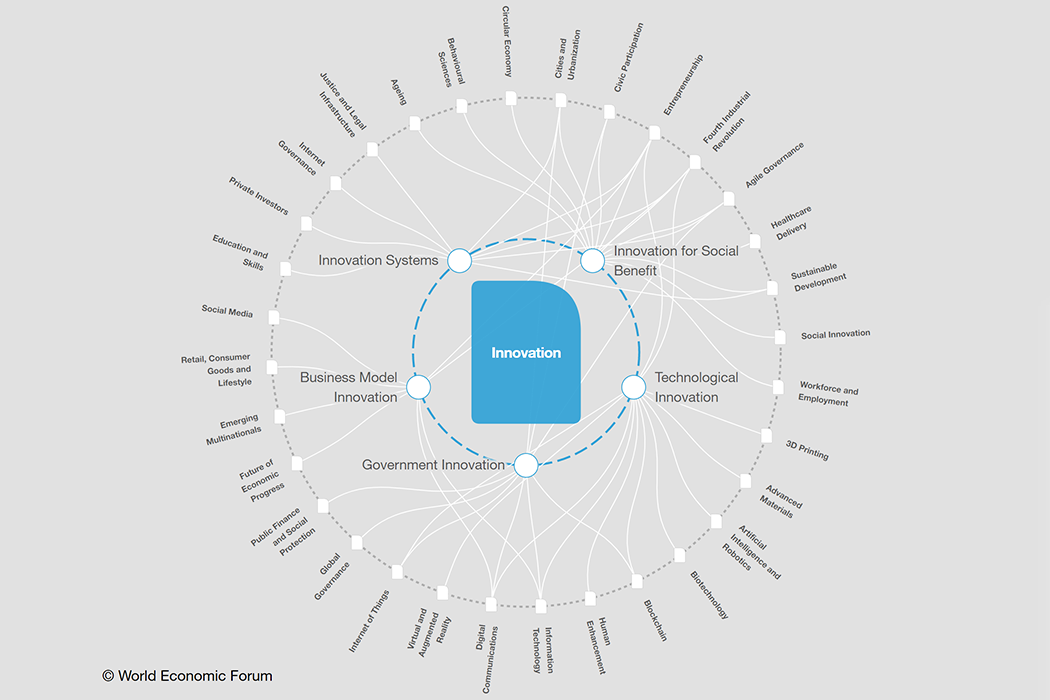

The consequences of the fourth industrial revolution can be seen in the shifts of our emphasis taking place around innovation. We are focusing more on our innovation spend on technological innovation. We are constantly looking at the changes to our existing business models to reflect these changes, and we are integrating our innovation systems to explore entirely new business models.

Source: World Economic Forum

We are connecting innovation more than ever. For example, choosing a blockchain technology requires significant collaboration and technology understanding. We are reliant on so much to generate “our”innovative solutions, far more than in the past. The interactive World Economic Forum map (screenshot shown above) is worth exploring. As you click on the links, you quickly recognize how interconnected our innovation has become. Not just in being able to produce accepted solutions but being having a ‘richer’ choice on where to focus our innovation efforts. Our innovation is becoming reliant on the fourth revolution and how it is all connecting us up, to provide our future growth through greater collaboration.

Doblin’s ‘Ten Types of Innovation’ – more relevant today than in the past

In the past, innovation was traditionally a product offering only – those within one specific domain of influence, as a one company solution. This has been progressively changing. We have been seeing innovation’s potential in exploring different combinations as outlined by Doblin’s “Ten Types of Innovation” view. It is the connecting-up of our operating environment digitally that is building this out even further.

The configuration, offering, and experiences are being pushed further by the growing impact of Industry 4.0. By integrating, exploring cross-disciplinary engineering, exploring the extended value chain, and through greater understanding of product function, customer experiences and managing innovation throughout the total life cycle are giving us a more expansive innovation canvas to work with. The shift in where to place your innovation efforts comes more and more from both horizontal and vertical solutions not previously imagined without this connected world.

Industry 4.0 has required us to advance our core skills and capabilities

We need to appreciate new digital business models and their impact. We are increasingly reliant on digital engineering and science. Our operations are yielding more innovation growth creating potential in end-to-end management, having available a digital factory that can respond, a greater reliance on so many things digital, ones that can lead to radically different innovation opportunities.

In products, there are so many variations of product extension, of how to position them and operate within multiple business models. There is scope to have radically different product development and processes to manage these. These are multiplying by this rate of industrial change.

Equally, the traditional supply chain has a very different potential when factories and operations become highly connected and start operating as Industry 4.0 entities; in the way they can be operated, responsive, in the supply networks and logistical integration opportunities, and in responding through different levels of automated planning and inventory management. All require different management.

As we connect more, customer experiences can hugely benefit. We can target, sell, and market on greater connecting knowledge. We can understand channel choice and connectivity better and provide more tailored pre- and post-sales support to manage the entire lifecycle as we continue to build the connected industry 4.0 environment.

The innovator is being challenged

So, what must we do as innovators? By recognizing and delivering on the fourth industrial revolution, we can start to think outside our classic product innovation boxes. We can shift our often-linear thinking as Industry 4.0 is the revolution that connects all the parts. Recognizing the transforming potential will revolutionize how we manage innovation going forward. It shifts our thinking and the management of innovation dramatically.

Innovation is fundamentally undergoing a radical change. Where is the front-end in all this? Is it simply just in an idea plucked from random connections, or is it found through all the digital connections we are continually making, brought about by the fourth industrial revolution? Are we capitalizing and capturing these as well as we should be? I feel we should explore this further in future posts. What do you think? Would that be valuable to you?

The original write up by Paul Hobcraft here.