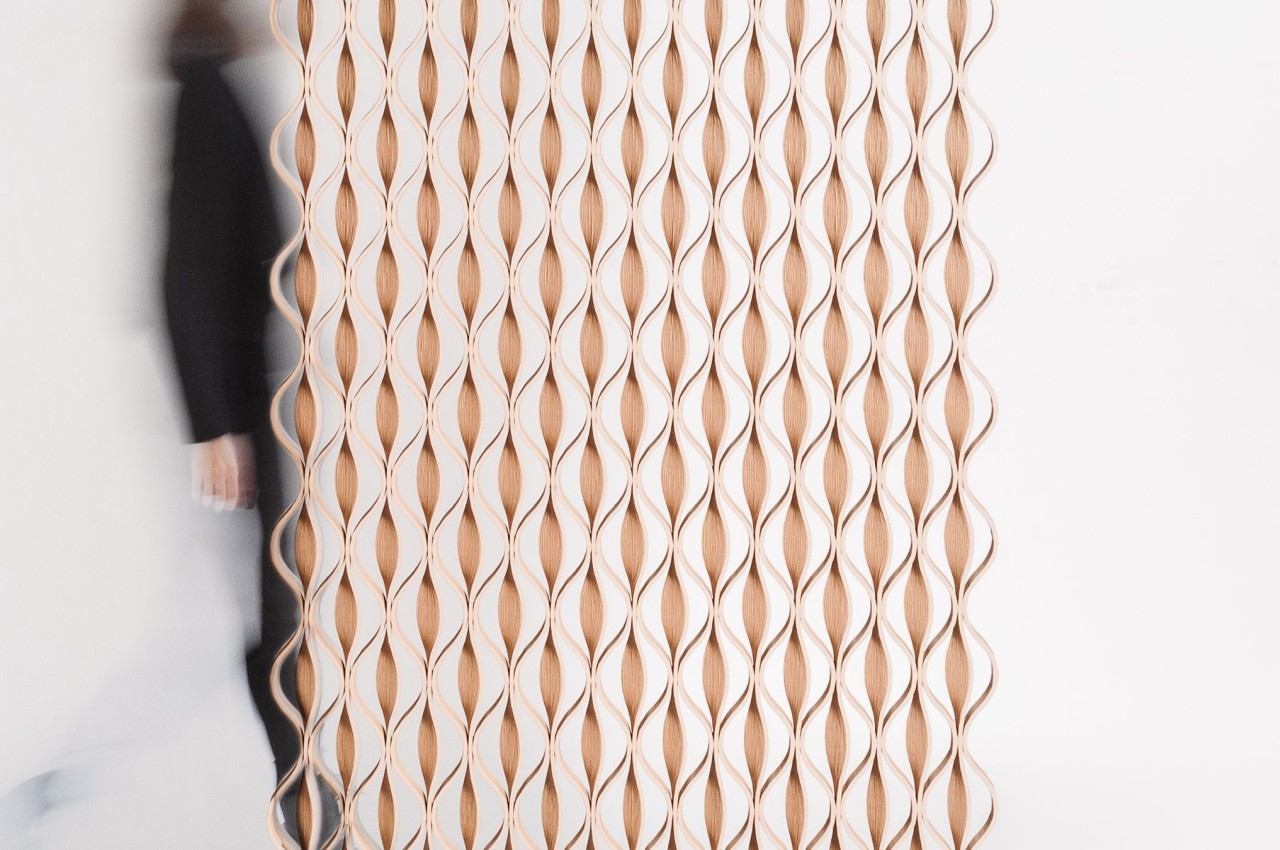

3D printing blasted the doors of creativity wide open by allowing almost anyone and everyone to create complex designs on demand. That market started with different kinds of plastic but soon supported other materials as well, including metal and even chocolate. The popularity of this style of design and production, however, also meant a surge in material waste, especially different kinds of non-recyclable plastics. There is a greater need for more sustainable alternatives, one that can perhaps even support a fully circular lifecycle. There is perhaps no better material that meets those requirements than wood, which is why this new 3D printed wooden partition screens and window coverings could very well represent the breakthrough that the design industry needs.

Designer: Aectual

Designers have a soft spot for natural, sustainable materials and wood is perhaps one of if not the most favored one. It is easily sourced, though not quickly replenished, has unique aesthetics and textures, and can decompose safely. That said, it’s not easy to form wood into complex shapes and structures, even if you carve out the design, and the material isn’t exactly easily reusable even after being recycled. This new 3D printed wood addresses all those shortcomings, offering an almost perfect material for bringing intricate, sustainable designs to life.

This sustainable new material is itself made from wood waste blended with some natural ingredients such as lignin and cellulose. It is then reinforced using vegetable fibers like flax or hemp to give it the same durability you’d expect from wood. The result is a composition that doesn’t just look like wood but also feels like the real thing. In fact, it even smells like real wood, a trait that’s hard to reproduce on other synthetic wood alternatives.

Aectual’s material, however, does something even better than wood. After a 3D printed wooden product reaches the end of its life, it can be shredded and then reprinted into some other or the same form. This creates a truly circular lifecycle where the material is reborn again and again as long as it retains its integrity and stability. And when it can no longer be reused, it still degrades and decomposes safely just like ordinary wood.

Of course, it’s a 3D printed material, so it’s almost trivial to create structures and shapes that would be extremely difficult if not impossible with regular wood. You can have intricate repeating patterns that join together with no visible seams, or alternating shapes that are made as a whole rather than composed piece by piece. It might be too early to claim a complete victory, as the process of creating this 3D printed wooden material might still be too involved and too costly, but it’s definitely a great start in producing a viable alternative to designers’ most-loved material.