Robotic lawn mowers don’t fail because they lack autonomy – they fail because owners stop trusting them. Missed patches, unexpected downtime, edge-case breakdowns: these are the reasons robotic mowing still hasn’t fully replaced traditional mowers on large and complex lawns. Lymow One Plus addresses that trust gap head-on. An evolution of Lymow’s tank-tread, boundary-free mower that has already attracted attention for its rotary mulching blades and steep‑slope capability. The new model builds on its predecessor with targeted hardware and software enhancements, including sharper SK5 blades, an improved airflow system, and advanced AI algorithms. For homeowners with demanding lawns, that means more confidence that the mower will get the job done right.

On the CES floor in Las Vegas, Yanko Design’s Radhika Seth sat down with Lymow co‑founder Charles Li to unpack what “replacement‑grade” actually means. Across the conversation, a few themes kept surfacing: ruthless user‑centric research, a willingness to admit and fix first‑generation flaws, and an almost stubborn insistence on “appropriate technology” over spec‑sheet theater. Lymow One Plus is the hardware expression of those values.

From Lymow One to One Plus, a mower built to actually solve North American yards

Charles describes Lymow One Plus as nothing less than a ground‑up evolution of the original product. “Lymow One Plus is a comprehensive upgrade of Lymow One,” he says. “It delivers a fundamental step up in cutting performance, stability, and long‑term reliability, while becoming noticeably smarter in complex, real‑world yard conditions.”

The target is very specific. Lymow One Plus is “a mower built to genuinely solve problems for large and complex lawns in North America, and increasingly, globally.” Instead of chasing flashy AI tricks, the team went back to first principles. “We didn’t design it to showcase flashy intelligence. Instead, we went back to the first principles and asked a very simple question. What does the user ultimately care about? The answer is very straightforward. Cut the grass short, and well, consistently, without hassle.”

That framing also ties into timing. Robotic mower penetration in North America is still under 5 percent as of 2025, and Charles is blunt that “no one is really successful in the robotic lawn market in the US” yet. The team sees 2026 as a genuine inflection point and wants Lymow One Plus positioned as the product that makes skeptical homeowners comfortable crossing the chasm.

Road‑tripping for R&D, and why a startup can ship what big brands will not

Charles makes it clear that Lymow One Plus is not the result of a whiteboard exercise. He talks at length about the legwork behind the company’s user research. “We’ve traveled through the U.S. I have visited more than 10 states. I’ve spoken to more than 30 families, three hours each one,” Charles explains. “You touch the grass through your own hands. You listen to the users from the deep, from your heart.”

That qualitative research is layered on top of a fairly serious engineering pedigree. “We do have very good accumulation in R&D,” Charles says. “Hardware level, mechanical design. Software level, we do have our accumulation, our autonomous algorithm. Our software team, most of our software team are from autonomous driving industry.” This is the same toolkit used to keep cars between lane markings, now repurposed to keep a mower reliably on task in a yard with patchy GPS and changing light.

There is also a cultural angle: Lymow is deliberately leaning into what a startup can do that a large appliance company often cannot. Charles contrasts their top‑down product decisions with the risk‑averse committees he remembers from his big‑company days, where “the quality manager is going to say, hey, you don’t have reference data” and after‑sales teams push back on anything too unconventional. For Lymow One Plus, that freedom shows up in choices like a front‑mounted mulching deck and tracked treads that would be harder to push through a conservative roadmap.

“Appropriate technology,” not tech for tech’s sake

When asked about Lymow’s long‑term vision, Charles does not talk about AI, RTK, or connectivity first. He talks about time. “Our core vision has always been using the best, or let’s say the most appropriate technology to give people their time back, to make them truly hands‑free,” he says. “Not to show off those fancy technology, but to understand what users need. We tend to say the most appropriate technology, rather than the best technology.”

That philosophy also reframes the yard itself. “A yard should be an extension of the home,” Charles notes in the same breath. If the home has already been transformed by robot vacuums and smart locks, Lymow wants the yard to feel similarly invisible in terms of maintenance, without forcing homeowners to become part‑time robotics engineers.

Specs are treated as a means to that end, not the end itself. Near the close of the interview, Charles relays something “from the bottom of our founder’s heart”: “Specs can tell you what a product is capable of, but they rarely explain how it feels to live with it… What truly earns trust is solving real problems in a pragmatic way, paying attention to small details, and delivering a level of reliability users can depend on day after day.” For Lymow One Plus, he says, “many of its most important [things] don’t stand out on a spec sheet, but users will feel them in how consistently the model works, how little friction it adds to daily life, and how thoughtfully it handles edge cases.”

Redefining “all‑terrain” around real backyards, not demo slopes

“All‑terrain” has become a throwaway phrase in outdoor robotics marketing. Charles is visibly wary of that. “Marketing is kind of tricky,” he says with a laugh. “A lot of manufacturers or lots of brands tend to use those, how can I put it, extreme words. Yeah, I can do everything. People use that in marketing words. ‘All terrain’ is a very strong word. It means a lot. It actually means a lot.”

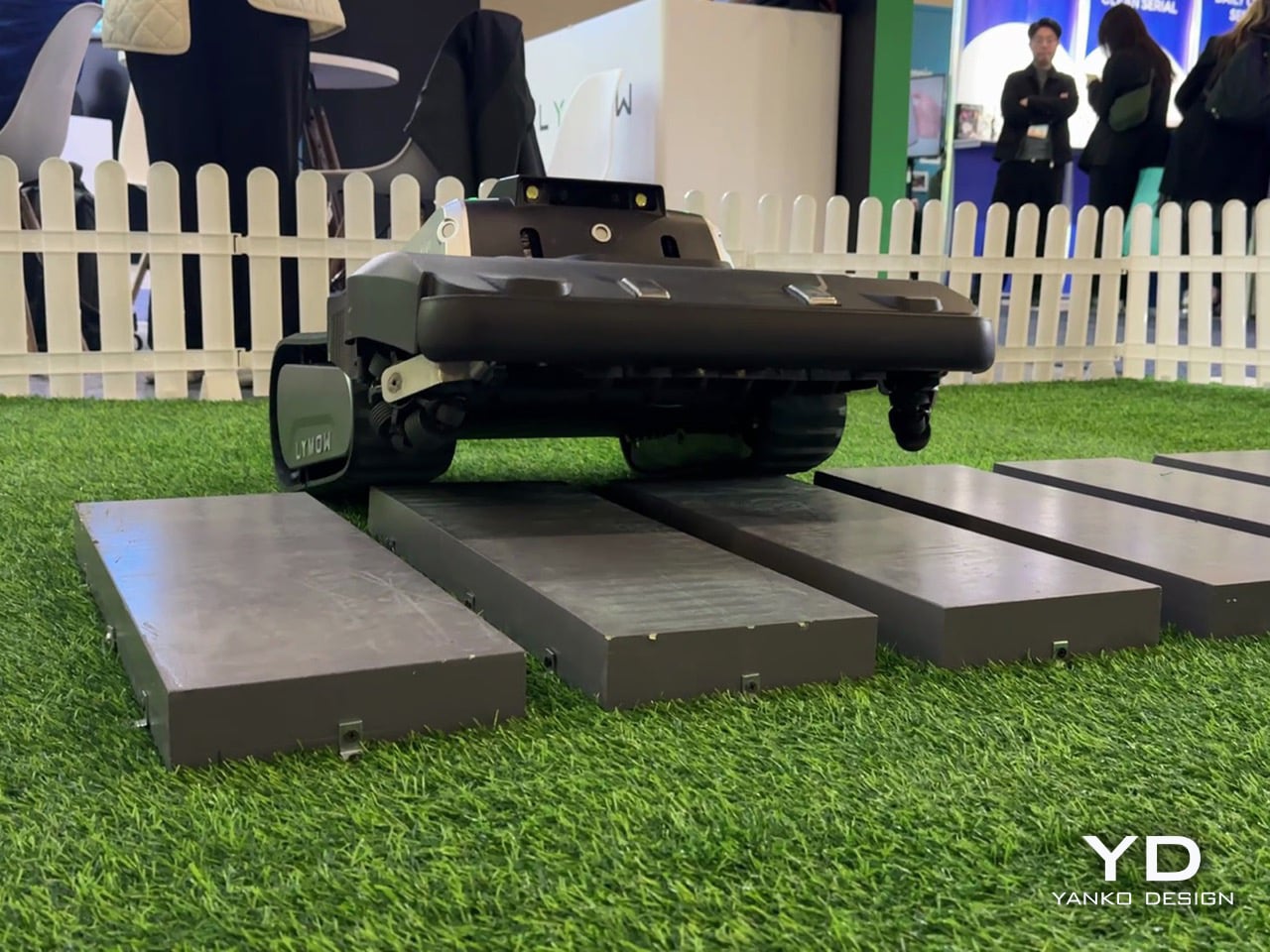

For Lymow, redefining it started again with fieldwork. North American yards, they found, are not just about inclines. They are about unpredictability. Open lawns with exposed tree roots, mole and rabbit holes, swings, trampolines, and informal forest edges became the true baseline, not edge cases. “In North America, these aren’t edge cases, but they are the baseline. So they became the scenarios we absolutely refused to fail at,” Charles says.

Grass type is another non‑negotiable benchmark. The team evaluated more than a dozen common cool‑ and warm‑season grasses, including thick, tough varieties that will quickly expose underpowered blades. That research directly informed Lymow’s rotary mulching blade system, which is designed to maintain cut quality across that diversity, not just on manicured test plots.

Fixing wet‑mowing failures and rebuilding the cutting system from the inside out

One of the most candid portions of the interview comes when Radhika asks what feedback from Lymow One directly shaped Lymow One Plus. Charles does not sugarcoat it. “One of the issues reported was our hub reliability during wet mowing conditions,” he admits. “In our first generation, the grass clippings could accumulate and eventually kind of damage the hub motor. We’re honest for this.” The response came in two stages. First, interim fixes and even unit swaps for affected early adopters. “For the people that are suffering this issue, we already swapped some new Lymow One units for them,” Charles notes. Mandy adds that it only affected a small number of users, but was taken seriously precisely because they did not want it to happen to anyone.

For Lymow One Plus, the team went much further. “We added dedicated debris shields to significantly reduce grass clippings and introduced scraping guards to prevent the clippings from getting trapped. And also we increased our motor strength by more than two times. Altogether, this changes fundamentally, entirely resolve these issues rather than masking it.” Underneath, the cutting system itself has been re‑architected. The cutting chamber volume has been expanded by roughly 50 percent, creating the airflow headroom needed for more aggressive mulching. Peak cutting power is up by about 50 percent as well, paired with SK5 industrial‑grade blade steel and redesigned geometry that generates a cyclone‑like airflow to lift grass before cutting. “When the blade is rotating, the grass will lift up, so you’re going to have a clean, even cut,” Charles explains.

Side discharge has also been rethought. Instead of leaving visible windrows, the Lymow One Plus deck is tuned to blow clippings out in a more even pattern. “We just kind of blow the grass clipping to make sure it’s not in the line… so in this case it’s healthier for your lawn,” Charles says. “You don’t have grass clippings in the line, but you have, like, an average… so that’s healthy.” Functionally, all of that shows up in three scenarios the team calls out as major improvement areas: wet and rainy mowing, heavy growth (long grass and dense weeds), and leaf‑heavy autumn yards. With the new airflow and power, Lymow One Plus can now lift and mulch thick vegetation that previously needed more favorable conditions or manual intervention, and it shreds fallen leaves more effectively so homeowners can “have a relaxed autumn.”

Why Lymow thinks Lymow One Plus can lead the category, not just join it

Asked to deliver a 30‑second elevator pitch against premium competitors, Charles narrows it down to three claims. “We’re the first one using rotary blades, multi‑rotary blades, the best cutting capability. And we’re the first one who can support the slope of 45 degrees, 100 percent, so let’s say the best climbing capability. And we mow up to 1.73 acres per day in our testing environment. So that’s an industry‑leading cutting efficiency.”

Those are bold numbers, but he quickly pivots back to something less easily quantified: trust. Lymow is not especially interested in feature‑by‑feature comparison charts. “We don’t spend much time positioning ourselves feature by feature against premium competitors,” he says. “What Lymow does is understanding user needs and systematically improving real user experience. So for us, more importantly, it’s the market education. It’s a heavy job, honestly, it’s a heavy job.”

That combination of specs and stance might be what makes Lymow One Plus interesting in a sea of CES robots. On paper, it is a tracked, rotary‑blade mower that climbs 45‑degree slopes, handles over an acre and a half per day, and navigates without boundary wires. In conversation, it is a case study in how a young hardware brand can own its mistakes, obsess over edge cases, and still talk about something as unsexy as “low friction daily life” with conviction.

If CES 2025 was Lymow’s coming‑out party for the original One, CES in Las Vegas now feels like the moment the company starts arguing not just that robot mowers can replace traditional ones, but that they should be held to the same standard of reliability and cut quality. Lymow One Plus is the company’s attempt to prove that out, one tricky backyard at a time.