What usually begins as a childhood memory of snapping LEGO Technic beams together has been reimagined at full scale by maker Matt Denton, who has turned one of the most recognizable Technic sets ever produced into a life-size, fully drivable machine. By scaling the 1981 LEGO Technic 8845 Dune Buggy more than tenfold and rebuilding every component through precise 3D printing, Denton bridges the gap between nostalgic toy engineering and real-world mechanics, creating a vehicle that not only looks like its plastic counterpart but can actually be driven off the workbench and onto the road.

This is not surprising as He’s known for turning tiny models into life-sized rigs that are drivable. Denton started with the original 1981 kit, which contains 174 pieces. Rather than simply make a large display model, he redesigned the buggy with two critical changes for practical use: he scaled it up by a factor of 10.42 times, based on 50-millimeter axle bearings, and converted it into a single-seat vehicle with a center-mounted steering wheel.

Designer: Matt Denton

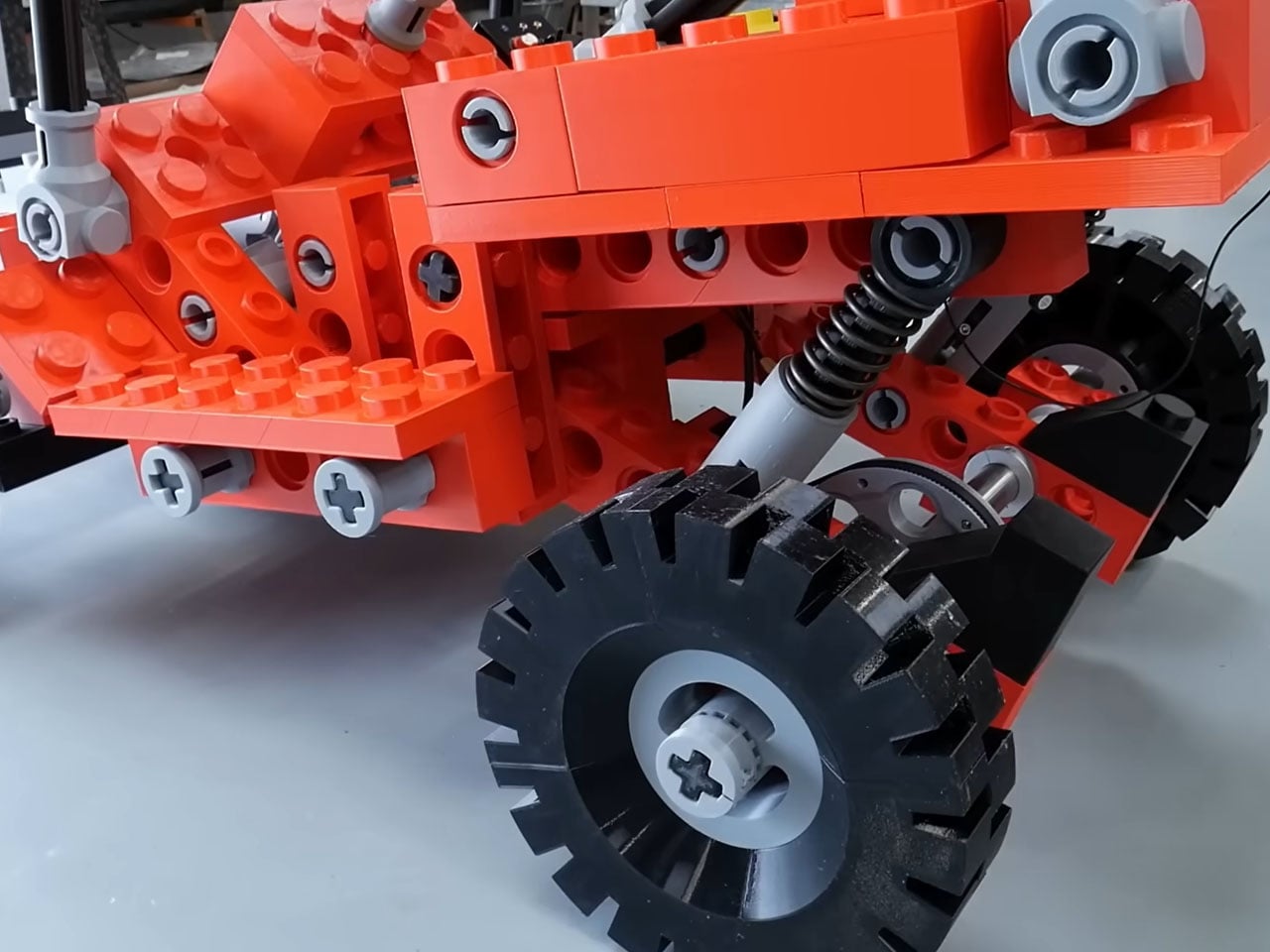

Every part was recreated using 3D printing. Denton used PLA filament and a belt-driven FDM printer, employing a 1 mm nozzle, two outer walls, and 10% infill to balance strength with manageability. Because of printing limitations, large plates and panels were split into smaller sections, so they would fit in the printer and to avoid warping. All curves and joints were first modeled precisely in CAD to ensure fit and performance under load. The final assembled buggy weighs about 102 kg — not light by any means, yet still light enough for hobby use. The build process reportedly took around 1,600 hours of printing and assembly, with numerous reprints required due to failed prints and printer issues.

To bring the build to life, an electric motor was mounted on the rear axle, connected via a belt-drive system. Steering is handled via a full-sized rack-and-pinion mechanism, molded as one giant LEGO-like piece, while the rear suspension arms connect over a steel tube to deliver stability. The tires themselves are printed from TPU wrapped around PLA cores, and each one weighs around 4.6 kg. They are manufactured as four quadrants for easier assembly and transport. Despite the technical hurdles, Denton succeeded as the buggy is completely drivable. During test runs, it demonstrated performance and handling that (while modest compared to a conventional motor vehicle) surpassed expectations for what began as a giant toy. That said, limitations remain as the vehicle shows signs of structural flex under load, and the electric motor setup delivers only modest power, limiting acceleration and top speed.

This project isn’t just a playful homage to a childhood classic; it’s also a demonstration of how modern 3D printing and careful engineering can push the boundaries of what’s possible, even with humble materials like PLA and TPU. It transforms a familiar childhood toy into a functional vehicle, and in doing so rekindles the wonder of imaginative play, but at a human scale. For hobbyists and builders, Denton’s dune buggy is an inspiration, as the line between toy and tool blurs, and a dream built in plastic bricks can eventually become something you can sit in and drive.