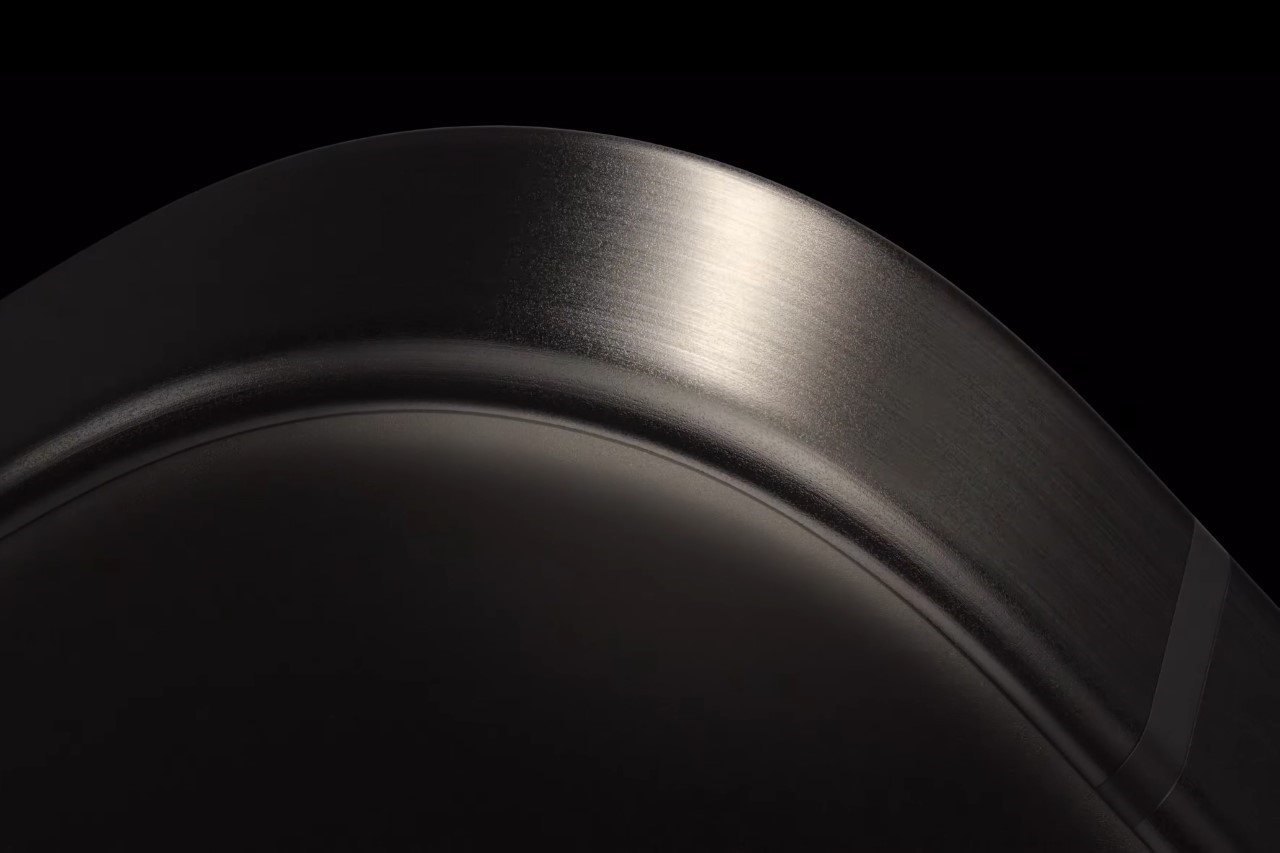

For a company that’s been so bullish on Aluminum (or aluminium as Jony Ive called it), Apple’s gradual shift to titanium feels like an end of an era. For two decades, Apple has pretty much revolutionized the use of aluminum in technology, but hey… it’s the future, we’re about to colonize Mars, and it’s high time we thought bigger, right? Well, the folks at Apple certainly think so, having unveiled their first iPhone made out of titanium. This isn’t the first time Apple’s made a gadget out of titanium (the Apple Watch Ultra from last year holds that distinction), and it certainly isn’t the first time any company has made a phone out of titanium. In 2015, the Turing Phone boasted a titanium body, and in 2017, the Essential Phone from Andy Rubin touted the same titanium construction. However, nobody does fanfare as well as Apple, and they’ve pretty much put a spotlight on the fact that the iPhone 15 Pro is their first-ever iPhone crafted from titanium; and not just ordinary titanium, but Grade 5 titanium. So… what is Grade 5 titanium, you ask?

What is Grade 5 Titanium?

Just by itself, Titanium is a standout metal known for its high strength, low density, biocompatibility, and corrosion resistance. Grade 5, commonly referred to as Ti-6Al-4V, is an alloy of titanium that includes 6% Aluminum and 4% Vanadium. This combination amplifies the metal’s strength, making it the go-to titanium grade for various high-performance applications in aerospace, racing, and human implants… and even a hot favorite for the EveryDay Carry (EDC) community.

Grade 5 vs. Regular Titanium?

Standard commercial pure titanium, often referred to as “Grade 1” or “Grade 2,” is robust and corrosion-resistant. However, when you mix it with aluminum and vanadium to produce Grade 5 Titanium, you get a metal that’s about twice as strong as its basic counterpart. Moreover, while pure titanium grades boast commendable corrosion resistance, especially against oxygen, Grade 5 takes it a step further by offering enhanced resistance against wear and fatigue. This unique combination of properties makes Grade 5 not just an upgrade but rather a different league, setting a gold standard in high-performance low-weight materials.

Comparing Titanium with Steel and Aluminum

- Strength and Weight: When pitted against steel, titanium stands out for its impressive strength-to-weight ratio. Titanium alloys, like Grade 5, offer strengths comparable to many steels, but at nearly half the weight. Aluminum, previously used in iPhone models, is lighter than titanium but doesn’t come close in terms of strength.

- Corrosion Resistance: Both titanium and aluminum resist corrosion well. However, titanium has the edge, especially in saline or chlorine-rich environments. Titanium’s corrosion resistance is significantly superior compared to steel, especially if it’s not ‘stainless’ or treated in other ways.

- Thermal Expansion: Titanium’s thermal expansion rate is closer to that of glass. When used in something like a smartphone, this becomes crucial. An iPhone screen is essentially glass, and by using a metal with a similar expansion rate, the risk of structural integrity loss due to temperature fluctuations is minimized.

- Flexibility: One of the understated properties of titanium is its flexibility. While steel can be rigid and aluminum might be too pliable, titanium strikes a balance, giving devices like the iPhone 15 Pro resilience against bending or deformation.

Is a Titanium iPhone really THAT special?

Truth be told, it seems like the titanium build is, in some ways, an over-correction for bend-gate. It wasn’t particularly a great time in Apple’s history, with people folding and snapping their aluminum iPhones in half, and since then, Apple’s worked hard to make sure people don’t turn their smartphones into tacos for the internet to enjoy. The company transitioned to Stainless Steel for their Pro iPhone models, and one could say that was pretty much as strong as anyone needed their iPhone chassis to be. Titanium is overkill at this point, especially given that with any iPhone, the true weakness lies in the glass front and back… and not the metal frame itself. Sure, the company’s developed Ceramic Shield, but drop it on the floor and it’ll still probably shatter while the outer metal frame doesn’t as much as get a lasting scratch. Now Apple hasn’t specifically highlighted the phone’s rugged durability and toughness, they’ve only mentioned how tough titanium is ‘as a material’, listing its accomplishments on the earth and in outer space. The phone isn’t made entirely of titanium either – it still has an internal aluminum framework, with an aerospace-grade titanium band on the outside. How does that benefit the consumer? Well, it doesn’t in the ways you think, but you’re bound to notice how luxuriously thin the iPhone 15 Pro is when compared to previous steel models. Apple also highlights that using Grade 5 Titanium also allowed them to make the chassis thinner and push the bezels even further to the edge, resulting in a more expansive-looking screen that’s just great to look at… if you’ve got upwards of $999 to pay for it!

Read More – iPhone 15 Pro Hands On: Lighter, Snazzier, and a real Pinky-Saver