Most of us think of corn as food. Maybe fuel, if you’re feeling generous. But a building material? That’s the kind of idea that sounds like it belongs in a sci-fi pitch until you look at what Mexico-based design practice MANUFACTURA has been quietly pulling off.

Their project is called CORNCRETL, and it is exactly what it sounds like: a bio-based construction material made largely from corn waste. Specifically, it combines limestone aggregates, dried corn residues, and recycled nejayote, which is the calcium-rich wastewater left over from nixtamalization, the ancient process of soaking corn in an alkaline solution that’s been used across Mesoamerica for thousands of years. That liquid, normally discarded after making tortillas and tamales, turns out to be a surprisingly useful ingredient in a next-generation building composite.

Designer: Manufactura

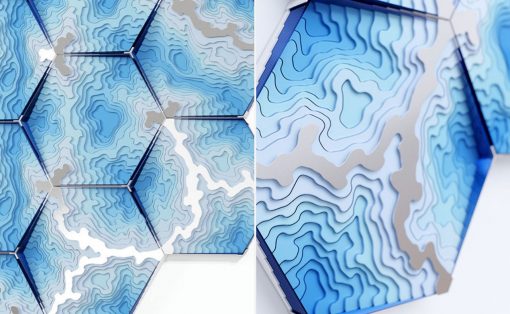

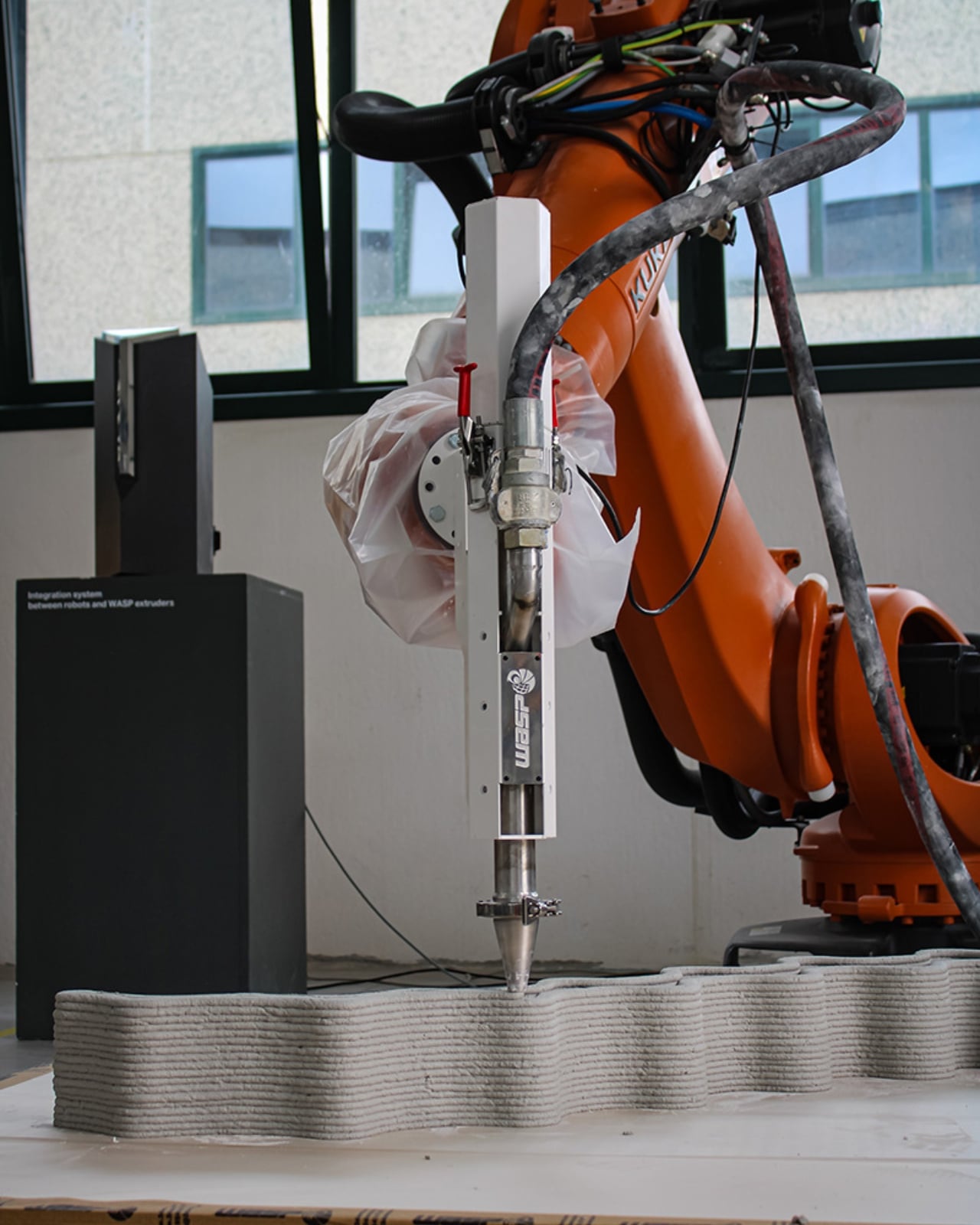

The name CORNCRETL is a clever mashup of corn and concrete, and the concept sits at the crossroads of ancestral knowledge and cutting-edge fabrication. MANUFACTURA drew direct references from pre-Hispanic Mayan construction techniques, which relied heavily on lime-based materials long before Portland cement ever existed. What they’ve done is take that legacy and run it through a robotic arm.

To produce the material, nixtamal waste is collected, dried, shredded, and pulverized down to a consistent particle size that works for extrusion. It’s then blended with mineral aggregates and organic binders to create a printable mixture. Printability tests were conducted using a WASP Concrete HD Continuous Feeding System integrated with a KUKA robotic arm, meaning the building process is precise, automated, and repeatable. The result doesn’t just look like a structural material. It performs like one.

One of the biggest knocks against conventional concrete is its carbon footprint. Cement production alone is responsible for a significant chunk of global CO2 emissions. CORNCRETL addresses this head-on. Compared to standard concrete, the material achieves up to a 70 percent reduction in carbon emissions. Part of that comes from how lime-based systems work: unlike Portland cement, they harden at room temperature and require lower calcination temperatures during production, which means less energy and fewer greenhouse gases released into the atmosphere.

Lime also brings a few bonus features to the table. It naturally regulates humidity and has self-healing properties for minor surface cracks, meaning the material can repair small imperfections on its own over time. For a building material, that’s a pretty remarkable quality.

The motivation behind CORNCRETL goes beyond just making something cool out of kitchen scraps. Mexico’s construction sector carries real environmental and social weight. Across the country, 64 percent of all waste is organic, and corn is a major contributor to that figure. At the same time, construction labor conditions remain difficult, with limited access to technical training and high occupational risk. MANUFACTURA’s approach proposes a circular material strategy that tries to address both sides of that problem, reducing waste while introducing more automated, accessible fabrication methods into the building industry.

The project has already moved beyond the lab. A full-scale prototype was built at the Shamballa open-air laboratory in Northern Italy, which is a long way from Mexico City but signals exactly the kind of cross-continental interest that a material like this can generate. It’s the kind of proof-of-concept that transforms a research idea into something you can actually stand next to.

CORNCRETL is led by designer Dinorah Schulte and project director Edurne Morales, with contributions from structural engineers and 3D printing specialists who helped optimize the material for real-world application.

What makes this project stick is that it doesn’t ask you to choose between tradition and technology. It holds both at once. Ancient techniques meet robotic fabrication. Food system waste becomes architectural possibility. And corn, of all things, might just have a future in the walls around us.