Before Gutenberg changed the world with movable type, knowledge traveled slowly, copied by hand from monastery to monastery. The printing press democratized information and sparked revolutions in science, religion, and politics. Now, a LEGO creator known as PrintNerd has brought that revolutionary technology into the hands of modern builders with a project that does more than sit on a shelf.

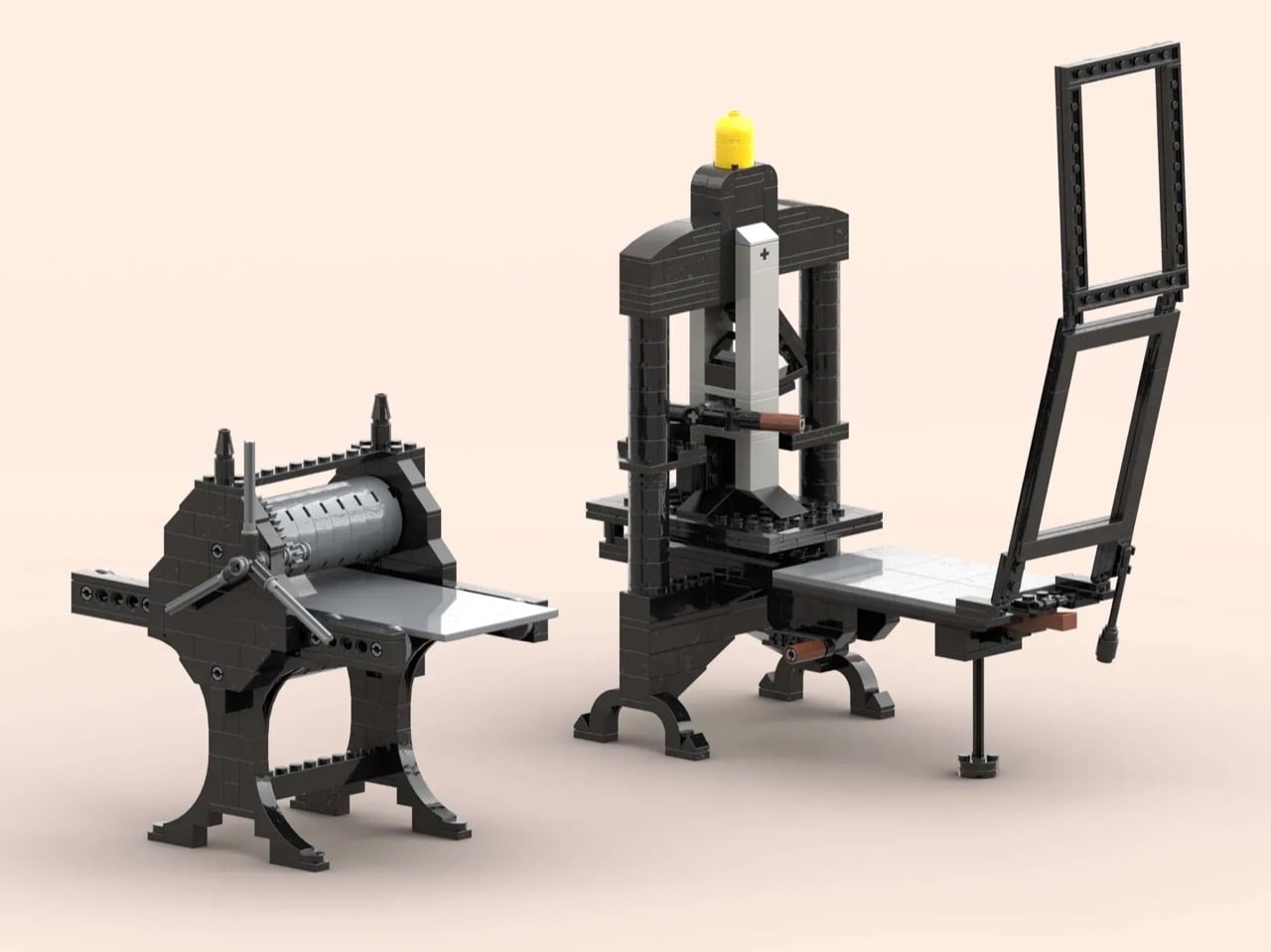

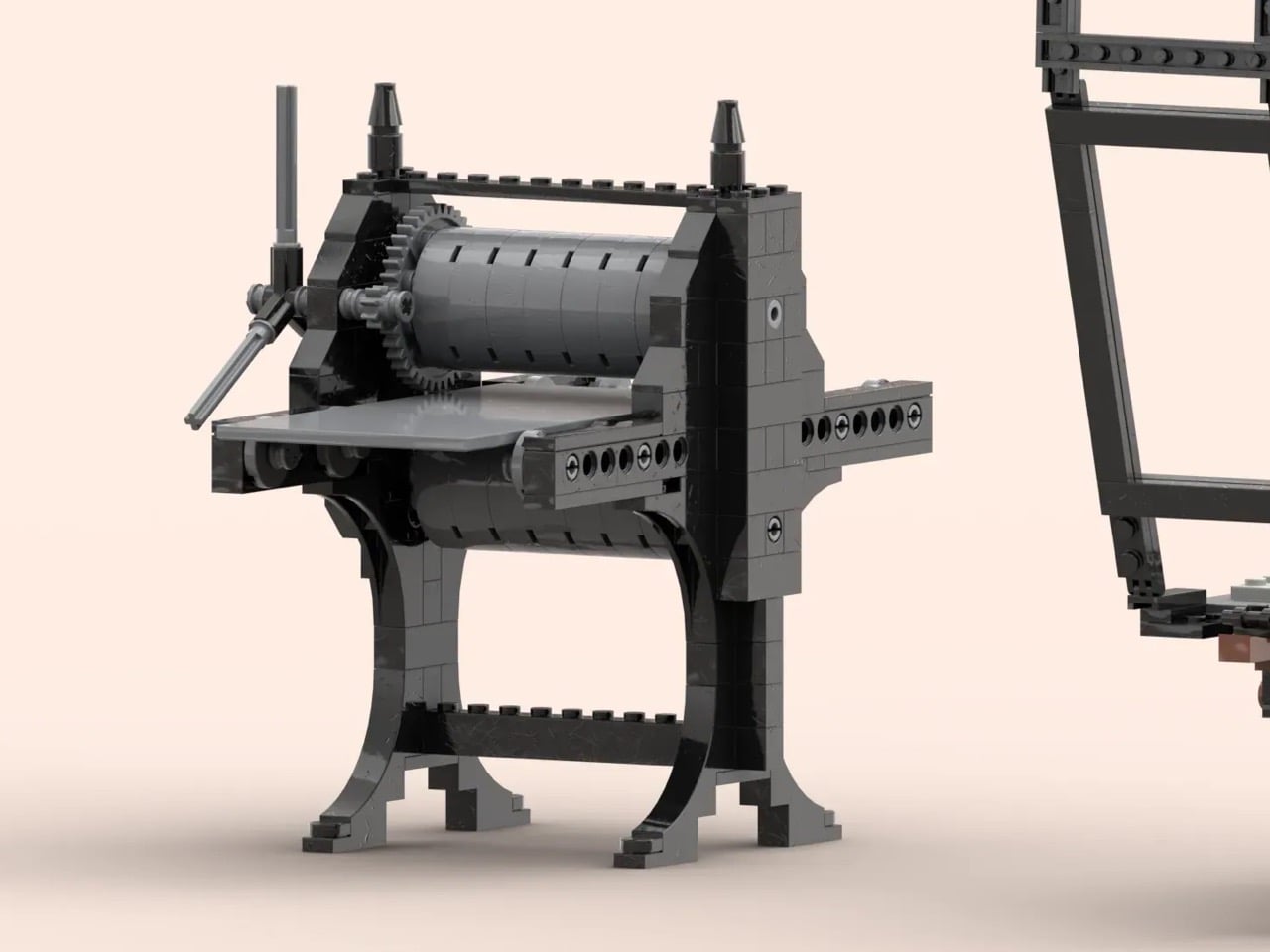

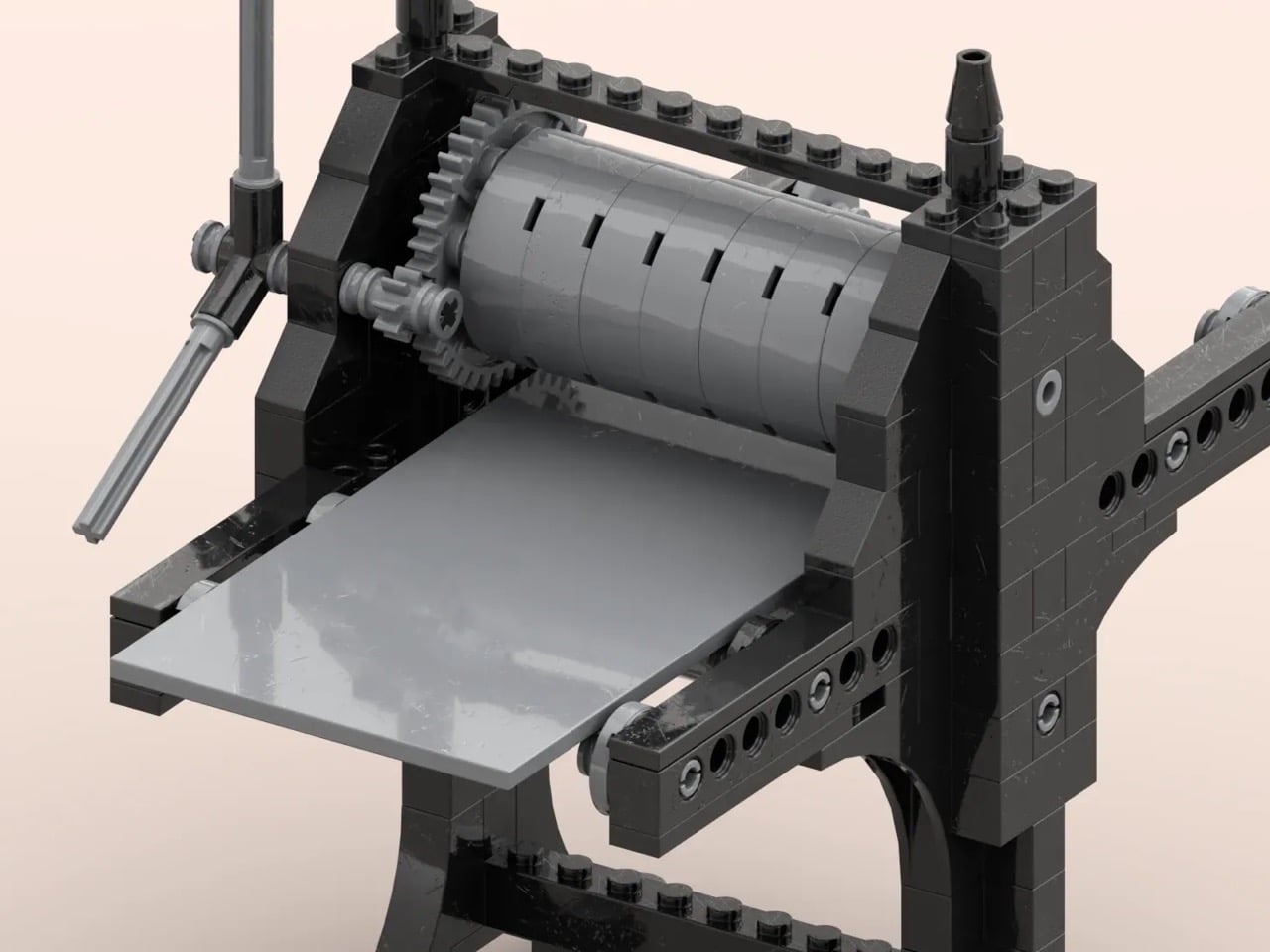

This LEGO Ideas submission features two fully functional printing presses built entirely from standard LEGO pieces. The lever-operated platen press and the roller-based press don’t just look the part. They actually work. Turn the handles, pull the lever, and watch centuries of engineering history play out in black, gray, and brown bricks. It’s a build that asks you to understand by doing, which is perhaps the most LEGO idea there is.

Designer: PrintNerd

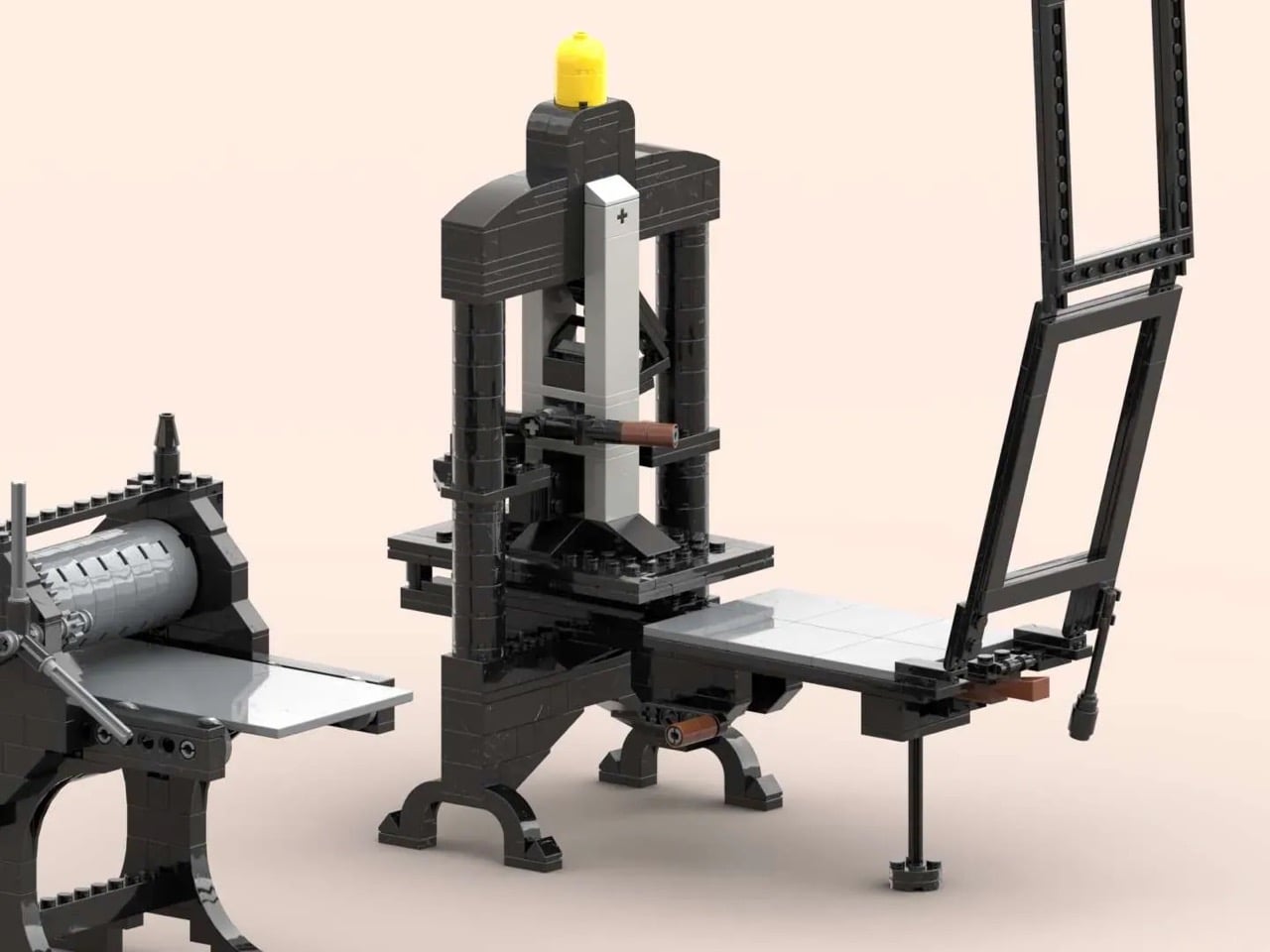

The larger of the two models is a 312-piece platen press inspired by the Albion Press, which was the workhorse of letterpress printing for over a century. You operate it by rotating a handle that moves the printing bed into position, then pulling down a lever to bring the platen into contact with the paper. The mechanism is completely exposed, which means you can actually see how the force transfers through the system. There’s a yellow minifigure head perched on top that serves no functional purpose whatsoever, but somehow makes the whole thing feel more approachable, less museum piece and more desktop companion.

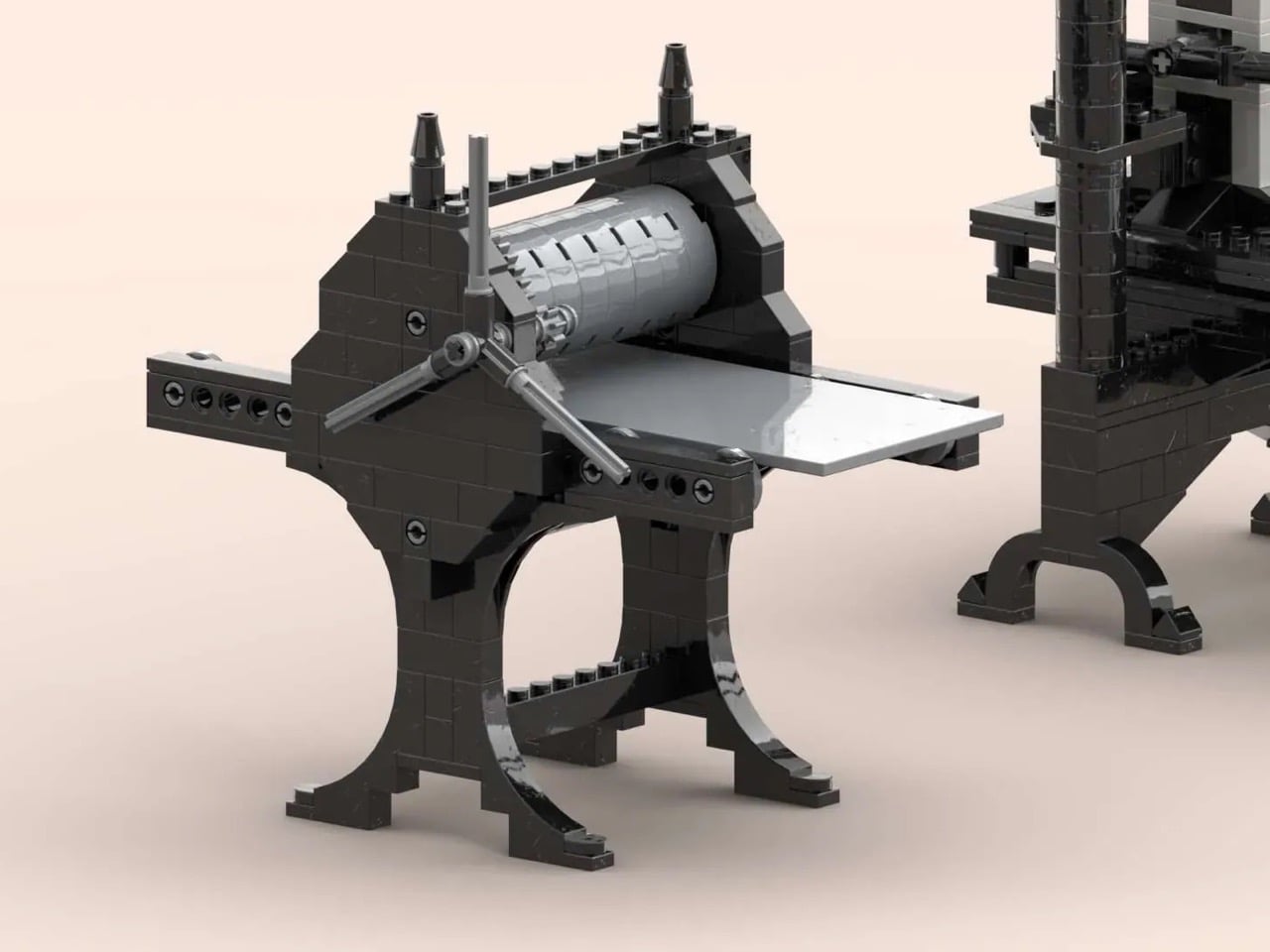

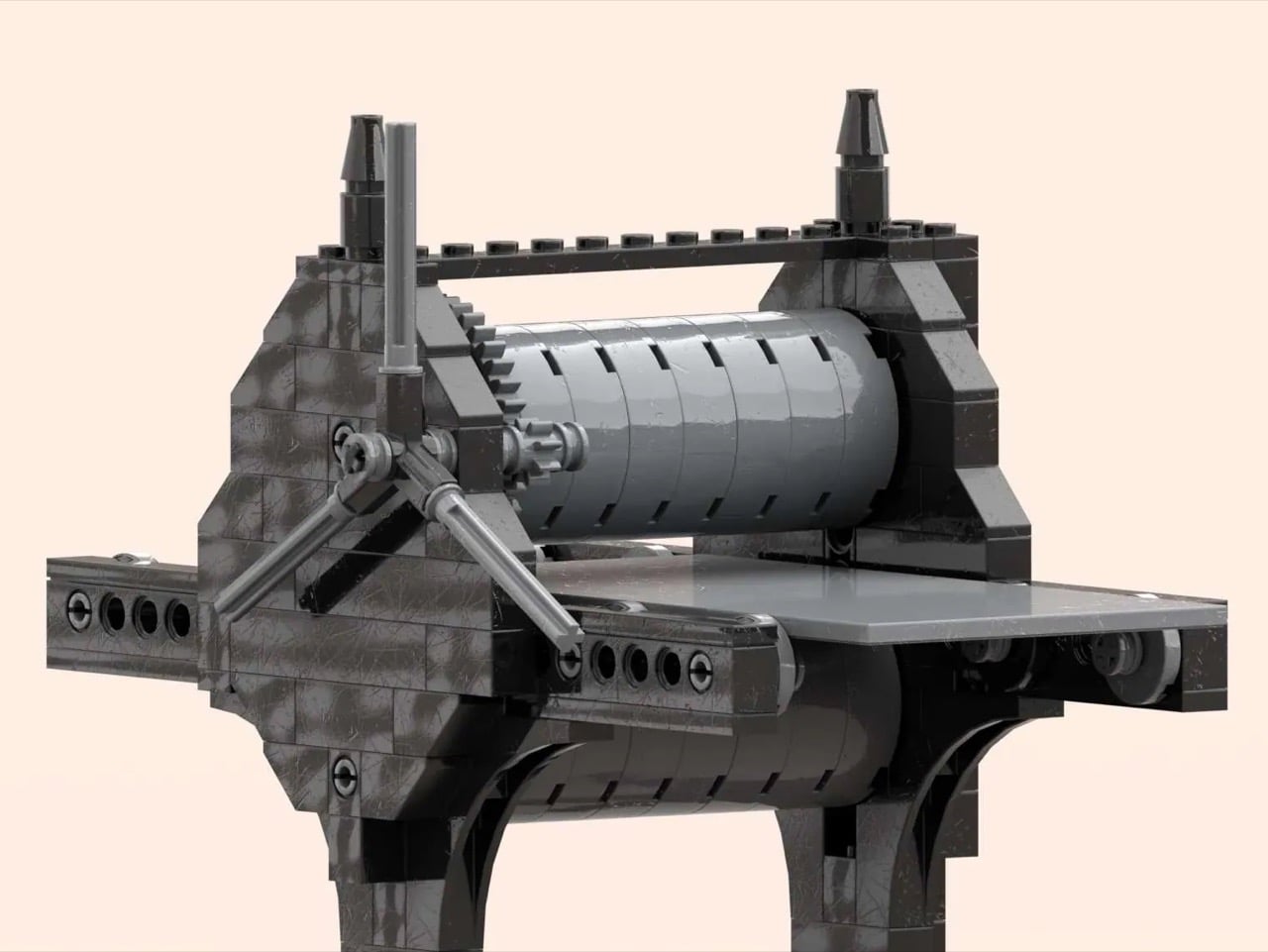

The roller press comes in at 163 pieces and takes a completely different approach to the same problem. Instead of applying pressure from above, it feeds the printing bed horizontally through a set of compression rollers. The cylindrical roller is the visual centerpiece here, flanked by gear mechanisms that let you crank the bed through manually. Both presses use that industrial black and gray color scheme that makes them look like miniature antiques, which is fitting since they’re based on machines that are still in active use by printmakers today.

PrintNerd built these for a community that already exists but has been working with a gap in their toolkit. There are LEGO enthusiasts who’ve been building relief plates from standard bricks for years, arranging studs and tiles into printable patterns, then taking them to external presses to make actual prints. The LEGO system has been perfectly capable of creating the artwork but incapable of providing the pressure. This project closes that loop. You can now build your plate, build your press, and complete the entire process without leaving the ecosystem. Color me impressed.

The project currently sits at 844 supporters with 376 days left to hit the 10,000 threshold needed for LEGO’s official review. It’s already earned Staff Pick status, which gives it better visibility on the platform but doesn’t guarantee production. LEGO Ideas has a notoriously unpredictable approval process. Plenty of worthy builds with strong support never make it to retail shelves. But this one has something going for it that most submissions don’t, which is genuine utility beyond novelty. You’re not just displaying it. You’re using it to understand how mechanical advantage works, how gears transfer motion, how centuries-old engineering principles still hold up. If you think that’s enough to make this MOC (My Own Creation) worthy of existing, go ahead and cast your vote for the build on the LEGO Ideas website!