Titanium is no longer confined to aerospace or medical tools. You now see it shaping everyday product design, from consumer electronics to furniture and wearables. Its high strength-to-weight ratio lets you create thinner profiles without sacrificing durability. Resistant to corrosion, scratches, and heat, titanium extends product life while reducing the need for frequent replacement.

Beyond performance, titanium delivers a refined tactile and visual experience. Its surface interacts with light to produce subtle tonal shifts that feel precise yet understated. You get products that feel premium without excess. With its long lifespan and recyclability, titanium supports responsible design choices, aligning innovation with sustainability and long-term value.

1. Generative Titanium Design

Generative design combined with additive manufacturing is reshaping how you approach product structures. Instead of solid, overbuilt components, you can now create lightweight forms guided by algorithms. These digitally evolved geometries use material only where strength is required, resulting in efficient, organic profiles inspired by natural systems such as bone and cellular growth.

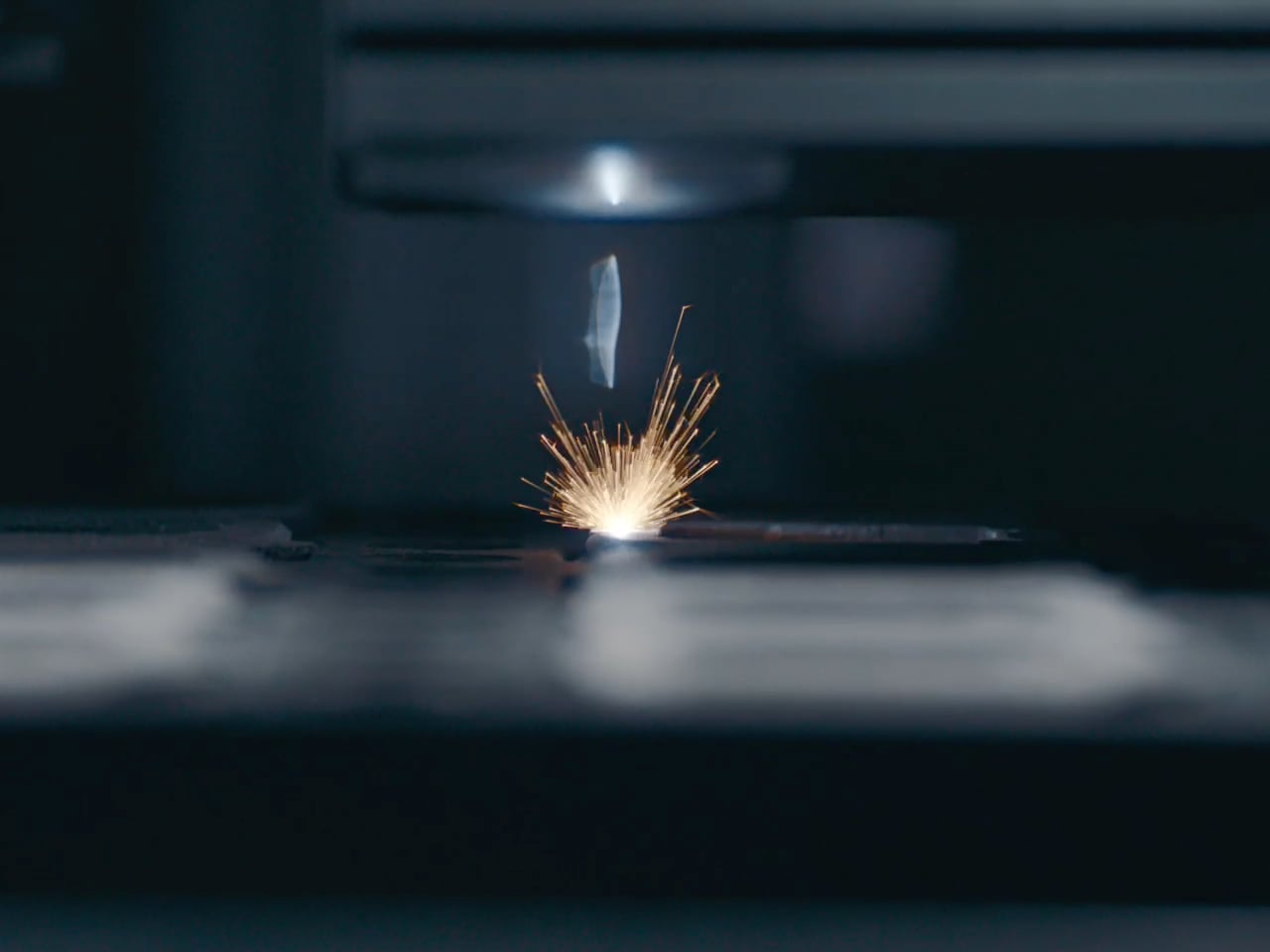

With 3D titanium printing technologies like laser powder bed fusion, you achieve precise stress-optimized components with minimal waste. Although production costs remain higher upfront, you benefit from reduced material usage, fewer assembly steps, and lower energy input, which delivers smarter products that balance performance, sustainability, and long-term value.

Apple’s move to 3D-printed titanium signals a deeper shift in product design, where manufacturing innovation directly shapes form, performance, and sustainability. By producing Apple Watch Ultra 3 and Series 11 cases through additive manufacturing using 100 percent recycled aerospace-grade titanium powder, Apple cuts raw material use by nearly half. The result feels identical to traditionally forged cases that are light, durable, and mirror-polished, yet it emerges from a process that builds only what the design truly needs.

Unlike subtractive machining, where excess titanium becomes waste, 3D printing constructs cases layer by layer with extreme precision. This unlocks design advantages beyond efficiency. Apple can now print internal textures that improve bonding between metal and plastic, enhancing waterproofing without adding bulk. The same approach enables thinner yet stronger components, such as the titanium USB-C enclosure in the iPhone Air. Here, sustainability is not an add-on, as it becomes the system through which better products are designed.

2. Anodic Color Effects

Titanium achieves color through anodic oxidation, an electrochemical process that alters its natural oxide layer rather than covering it. You are not applying paint, but you are changing how the material interacts with light. This creates rich hues—ranging from soft blues to deep violets—that shift subtly with angle and atmosphere, giving products a living, responsive surface.

These anodic finishes are not only expressive but enduring. They resist UV fading, corrosion, and salt exposure far better than conventional coatings. For product design, this means long-lasting color without maintenance or reapplication. You get visual depth, material honesty, and performance aligned in a single, permanent finish.

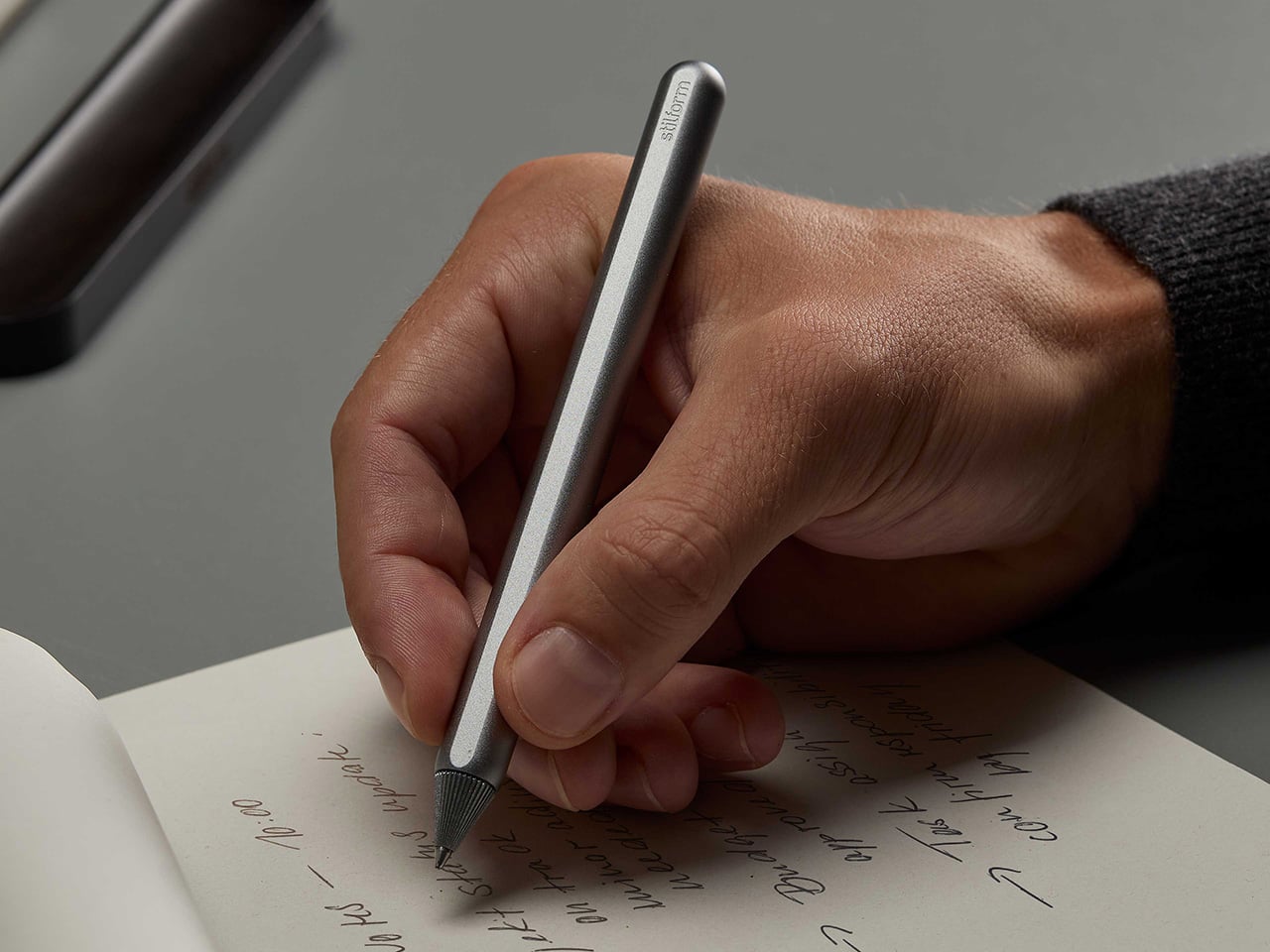

The AEON Ballpoint is defined by disciplined product design rather than visual flair. Its form is reduced to a clean metal cylinder, free of branding, excess seams, or decorative elements. The matte finishes are chosen for grip and durability, not ornament. Every curve is calibrated for the hand, making the object feel purposeful and precise from the first touch.

Function drives every detail. The front-end twist mechanism is hidden where the fingers naturally rest, allowing seamless operation without changing grip. Weight distribution is carefully balanced for sustained writing comfort, while subtle flat facets prevent the pen from rolling on a desk. Titanium

3. Smart Glazing

Titanium-doped glazing represents a new generation of high-performance glass designed to actively regulate indoor climate. By depositing ultra-thin layers of titanium dioxide onto glass surfaces, this technology achieves spectral selectivity—reflecting infrared heat while allowing visible light to pass through. The result is improved thermal efficiency, reduced heat gain, and lower dependence on mechanical cooling systems, even in buildings with expansive glass façades.

Beyond performance, this glazing supports biophilic design intent. Clear, untinted views preserve a visual connection with the landscape, allowing natural light to shape interior experience. The space remains thermally stable yet visually open, creating a calm, nature-connected interior envelope.

The Prism Titanium Beer Glass is designed to elevate the act of drinking through precision, material integrity, and restrained design. Crafted in Japan by Progress Design, the glass features an ultra-thin lining of 99.9% pure titanium, engineered to reduce bitterness and eliminate metallic aftertastes, allowing the true character of the beverage to emerge. Its flared rim enhances aroma and refines mouthfeel, while the aerospace-grade construction ensures durability, corrosion resistance, and long-term performance. Every element reflects a balance between advanced technology and traditional Japanese craftsmanship.

Visually understated yet distinctive, Prism’s light-reactive finish subtly shifts with movement, adding depth without excess. Etched motifs draw from enduring Japanese symbols of continuity and prosperity, reinforcing its sense of permanence and purpose. Designed to be used daily rather than displayed, the Prism Titanium Beer Glass prioritises clarity, tactility, and intention—transforming an ordinary pour into a composed, well-considered experience grounded in design excellence.

Click here to Buy the Prism Titanium Beer Glass: $99

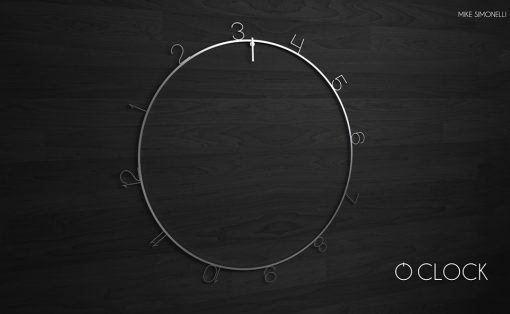

4. Minimalism Enabled by Strength

Titanium’s exceptional tensile strength enables a new approach to product and structural design defined by extreme slenderness and visual lightness. Components can be engineered with significantly reduced mass while maintaining high performance, allowing forms to appear almost invisible. This material efficiency supports refined proportions and uninterrupted lines, enhancing both functionality and aesthetic clarity.

By minimising structural bulk, design emphasis shifts towards spatial sequencing and visual flow. Slender supports and cantilevered elements create open, fluid compositions that maximise usable space while reinforcing a sense of weightlessness. This form of minimalism is not decorative but technical—rooted in advanced engineering and material intelligence, where precision-driven design allows the surrounding context and spatial experience to take precedence.

The TriPro Stand is a compact, precision-engineered multitool designed to deliver high functionality within a remarkably small form. Crafted from durable titanium alloy, it integrates 15 essential tools into a structure no larger than a finger while maintaining a lightweight profile of just 56 grams. Its design prioritises strength, corrosion resistance, and refined minimalism, demonstrating how advanced materials allow complex functionality without added bulk. The result is a discreet yet highly capable everyday carry tool that balances performance with visual restraint.

Each function is thoughtfully embedded to support practical, real-world use. Features such as the integrated phone stand, modular screwdriver system with magnetic bit storage, SIM ejector, pry bar, spoke wrench, folding scalpel, sharpener, and emergency glass breaker are engineered for reliability rather than novelty. Measuring 8 cm in length, the TriPro Stand exemplifies intelligent product design—where precision manufacturing, material efficiency, and purposeful detailing converge to create a durable and dependable multitool.

5. Exceptional Fatigue Resistance

Titanium demonstrates exceptional resistance to cyclic fatigue, enabling it to withstand repeated stress and loading without cracking, deforming, or compromising structural integrity. Unlike many conventional metals that gradually weaken under continuous use, titanium retains its mechanical performance across millions of stress cycles. This inherent endurance allows designers to rely on slimmer, more efficient components without sacrificing reliability.

Such fatigue resistance makes titanium particularly suitable for products intended for frequent handling and long-term use, including hinges, fasteners, wearables, tools, and precision mechanical interfaces. By maintaining consistent performance over time, titanium enhances safety, durability, and functional stability. Its ability to endure prolonged mechanical demand reinforces its position as a material defined not only by strength and lightness, but by sustained performance and endurance-led design.

Fasteners positioned in confined or obstructed spaces often reveal the shortcomings of conventional ratchets, which require a wide swing arc to function effectively. The Titaner EDC Ratchet System is engineered specifically to overcome this limitation through a precision 4-degree swing arc, enabling forward motion with minimal hand movement. Its compact ratchet core weighs just 29.8 grams, yet delivers clear tactile and audible feedback, ensuring accurate engagement even in environments where access and visibility are severely restricted.

Despite its minimal size, the system is designed for high torque and long-term durability. A dual-lock gear mechanism efficiently transfers force without play, while a flip-based directional control replaces fragile thumb levers, reducing complexity and potential failure points. The modular configuration allows the tool to be adapted into T-, L-, or I-shaped formats using extension bars, optimising leverage and reach. Manufactured from GR5 titanium with hardened M390 steel gear teeth, the Titaner EDC Ratchet System combines corrosion resistance, structural integrity, and refined mechanical performance in a compact, purpose-driven design.

The integration of titanium into product design marks a shift from visual heaviness to intelligent lightness. No longer perceived as cold or industrial, titanium functions as a responsive material that balances strength, precision, and refined tactility. Its use enables objects that are lighter, more durable, and visually restrained—defining a new language of design where performance, longevity, and elegance are seamlessly aligned.