Most sports are dictated by the skill and prowess of the athletes competing but there are also some sports where the sportswear and footwear that they wear can contribute to how they perform. But not all of these sports have customizable or flexible footwear to help the athletes out. Bobsleigh is one such sport and with the Winter Olympics a year away, Germany is partnering with BMW to give their team better footwear to help them compete at the top level.

Designer: BMW

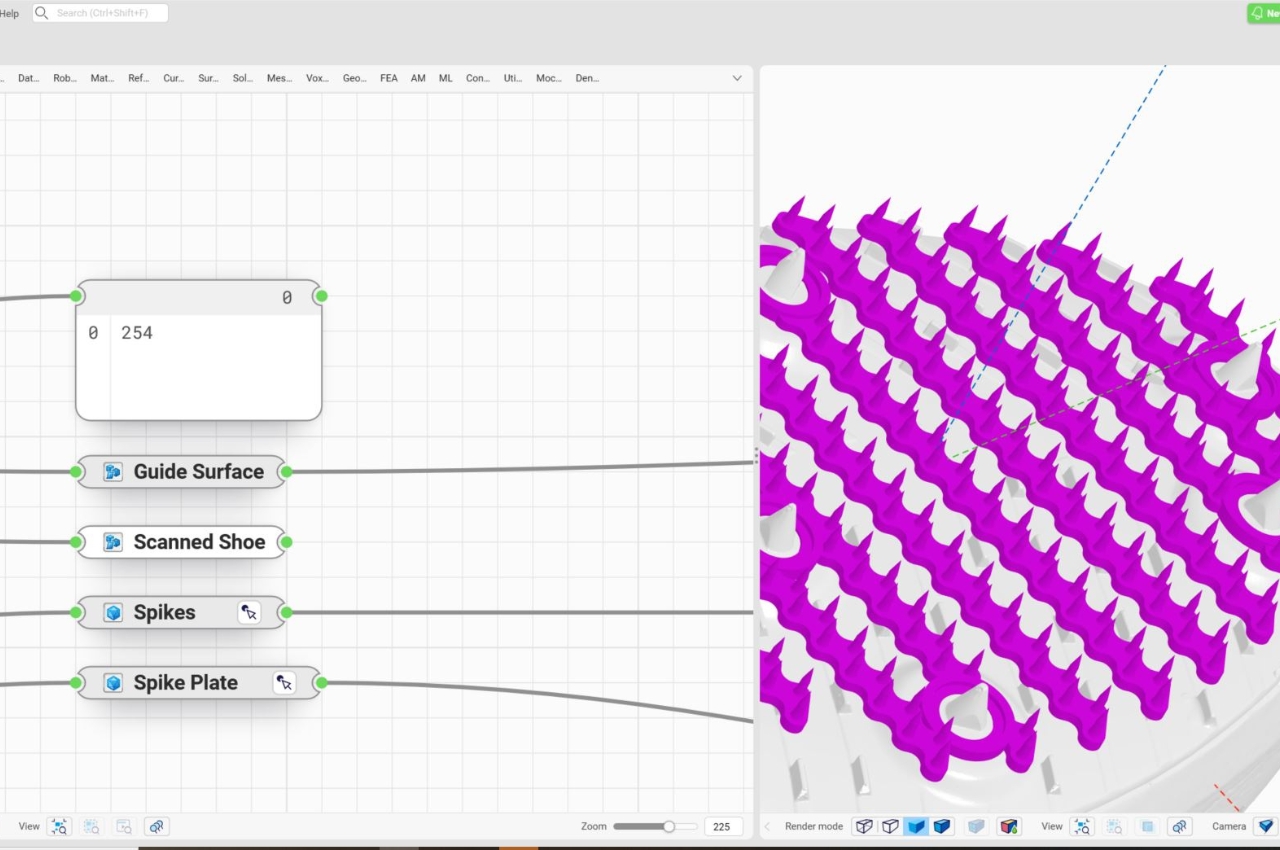

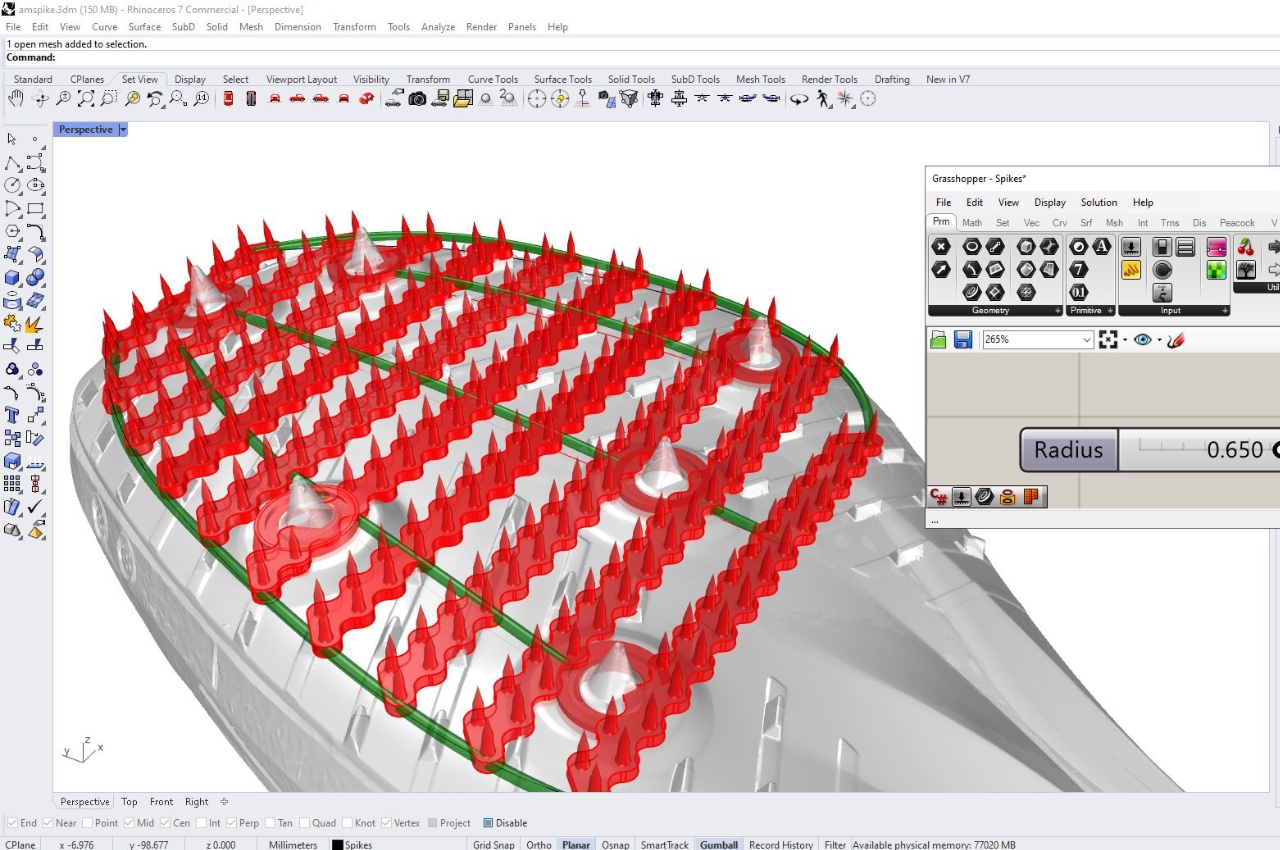

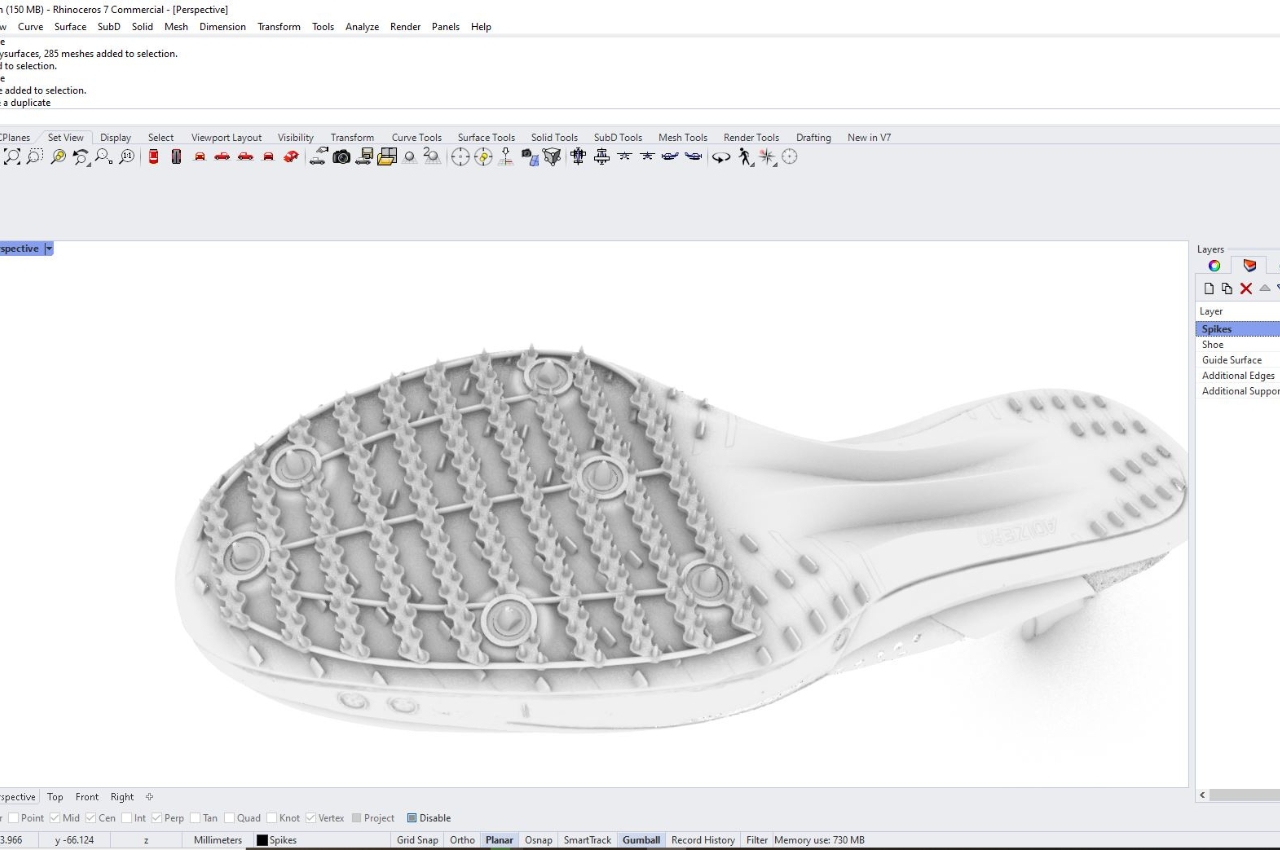

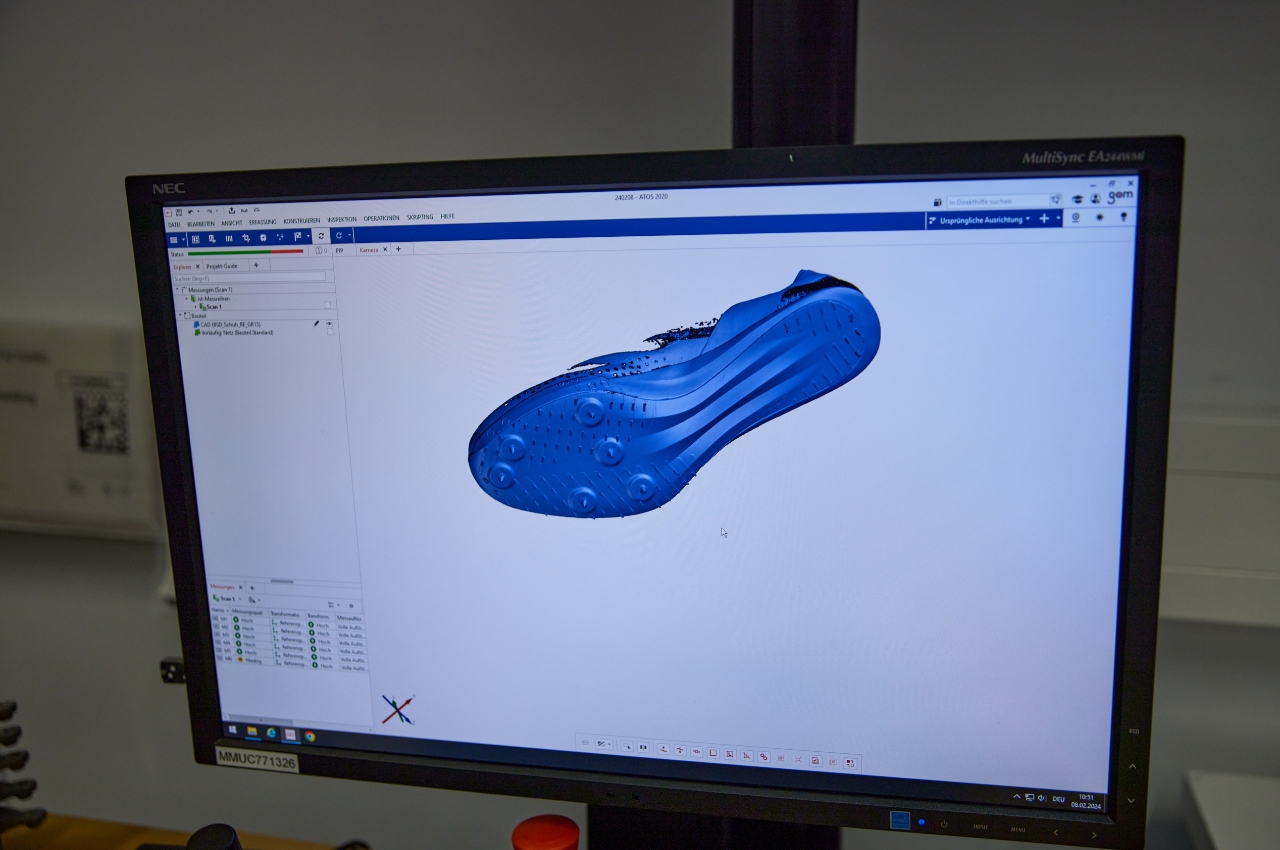

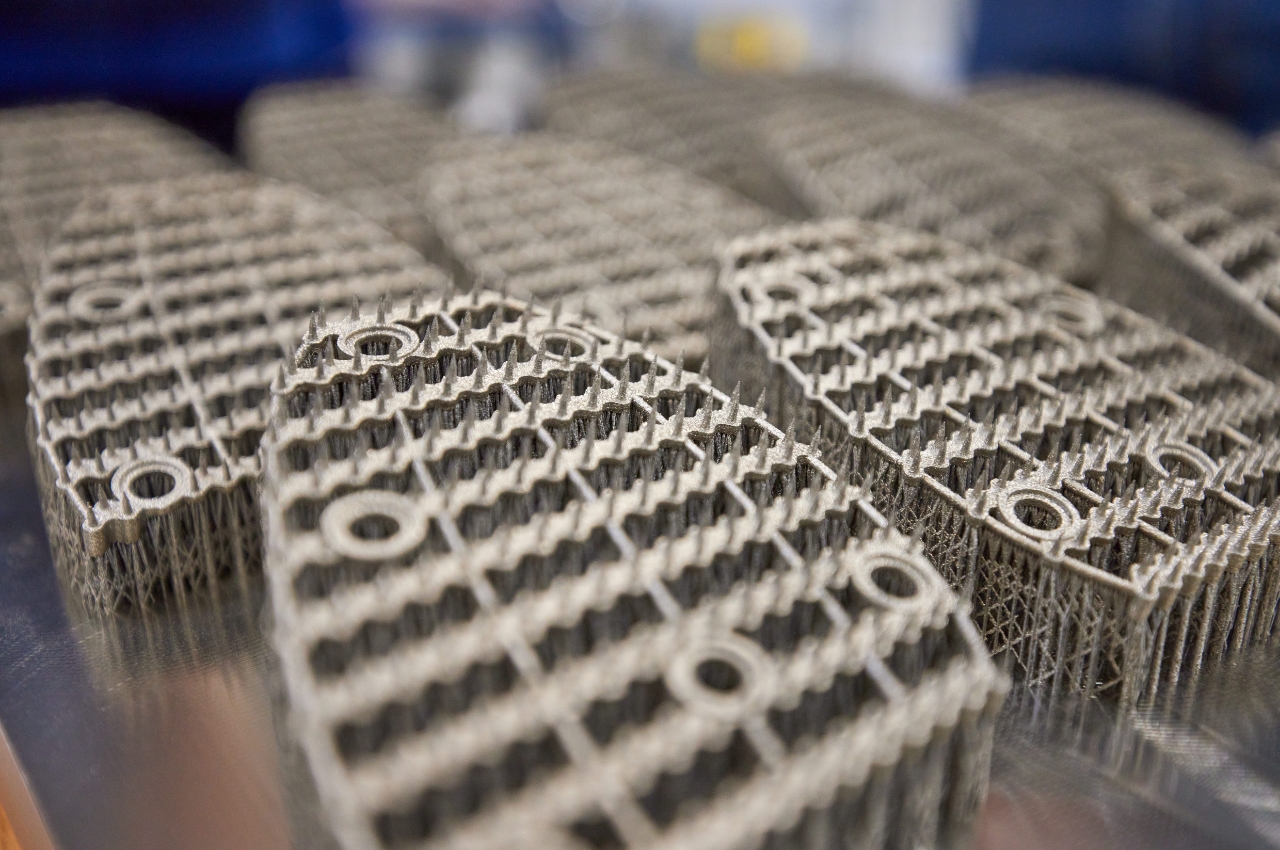

The BMW Group is the technology partner of the German Bobsleigh, Luge, and Skeleton Federatin (BSD) and they have come up with customizable spiked shoes for the bobsleigh team using the power of 3D printing. Regular bobsleigh footwear have defined rows of nails attached to the toe area but these are not replaceable or moveable. Based on track and field shoes, which are more flexible, they came up with threads for screw spikes which are used to attach spike plates on which spike nails can be distributed.

This means that the spikes can be adjusted to a large selection of shoe styles, sizes, and other aspects to make them more comfortable and suitable for the athletes’ needs. You can also adjust the material and geometry of the plates and the placement of the spike nails, giving better acceleration according to the power transmission on the ice. And since 3D printing is used, they get to be more flexible and test out the spikes and make adjustments, without having to spend a fortune and spend so much time manufacturing.

They were able to test out the spike plates during the Bobsleigh World Cup (which ends later this month) and so far, they were able to get positive feedback from the athletes that they made them for. Of course there are still changes that need to be made but they do have 11 months to go for it before the Winter Olympics in February 2025. We’ll also see by then what effect these spikes have on the German team’s performance.