Sustainable fashion has just begun, and we believe the concept will continue spreading as more companies consider such a flourishing ecosystem of materials, processes, and products. It is part of a circular economy where waste materials are being shared, reused, repaired, recycled, or refurbished to create new products. It is one of the many ways to attain a better planet for the next generation and we are glad that many scientists and researchers are putting so much effort into this level of development. For sustainability to happen, it doesn’t always mean you take advantage of all the usable waste for recycling–it can also mean creating new materials, designs, and more sustainable ways for the fashion industry. What has just been introduced and what could be beneficial to the game is a new biomaterial by Modern Synthesis.

Designer: Modern Synthesis

Modern Synthesis is a startup that works on biomaterial innovation for the fashion industry, aiming to identify radical and regenerative material solutions that could significantly reduce plastic pollution and emissions. Specifically, the company has already started to grow fabric that can be used for fashion from microbes. There is science behind this idea, which is why Modern Synthesis convinced people to fund its research, and it has proudly shared that it received more than $4 million in seed funding from AgFunder to develop a microbial textile platform.

Modern Synthesis founders Jen Keane and Ben Reeve have recognized the need for more sustainable materials and solutions. The funding from AgFunder is expected to help the team’s expansion, build a pilot facility in London, and finally ramp up production. The potential of this project is huge, so there is a bit of urgency when it comes to putting people and systems to work.

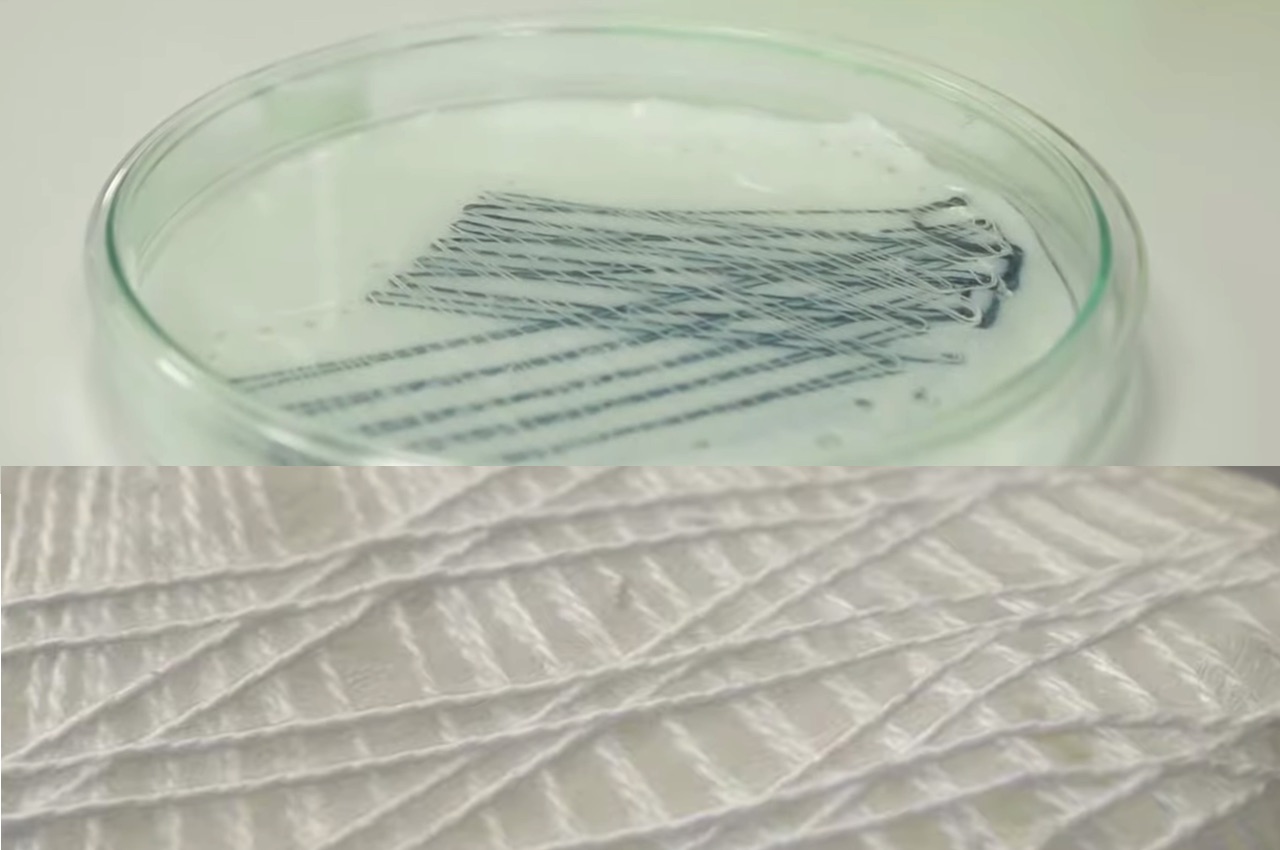

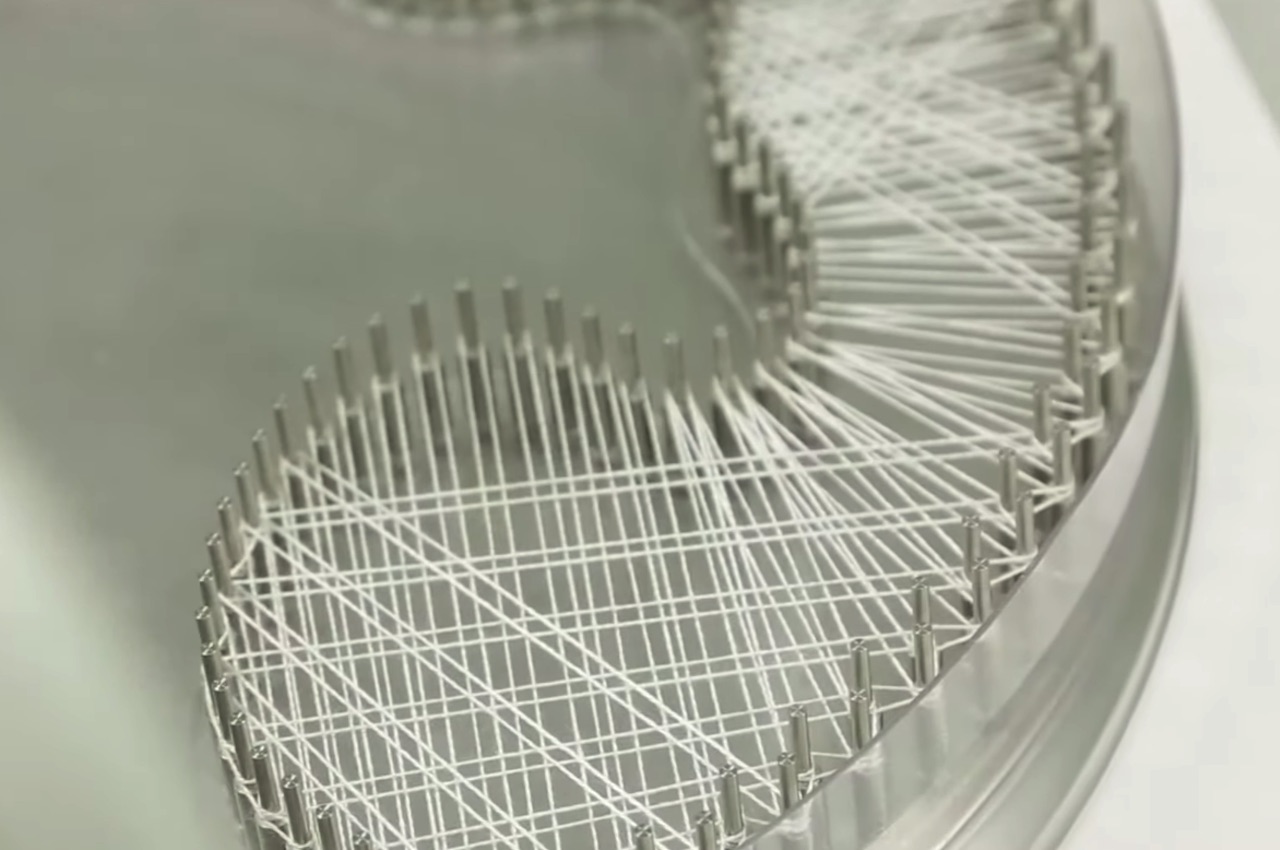

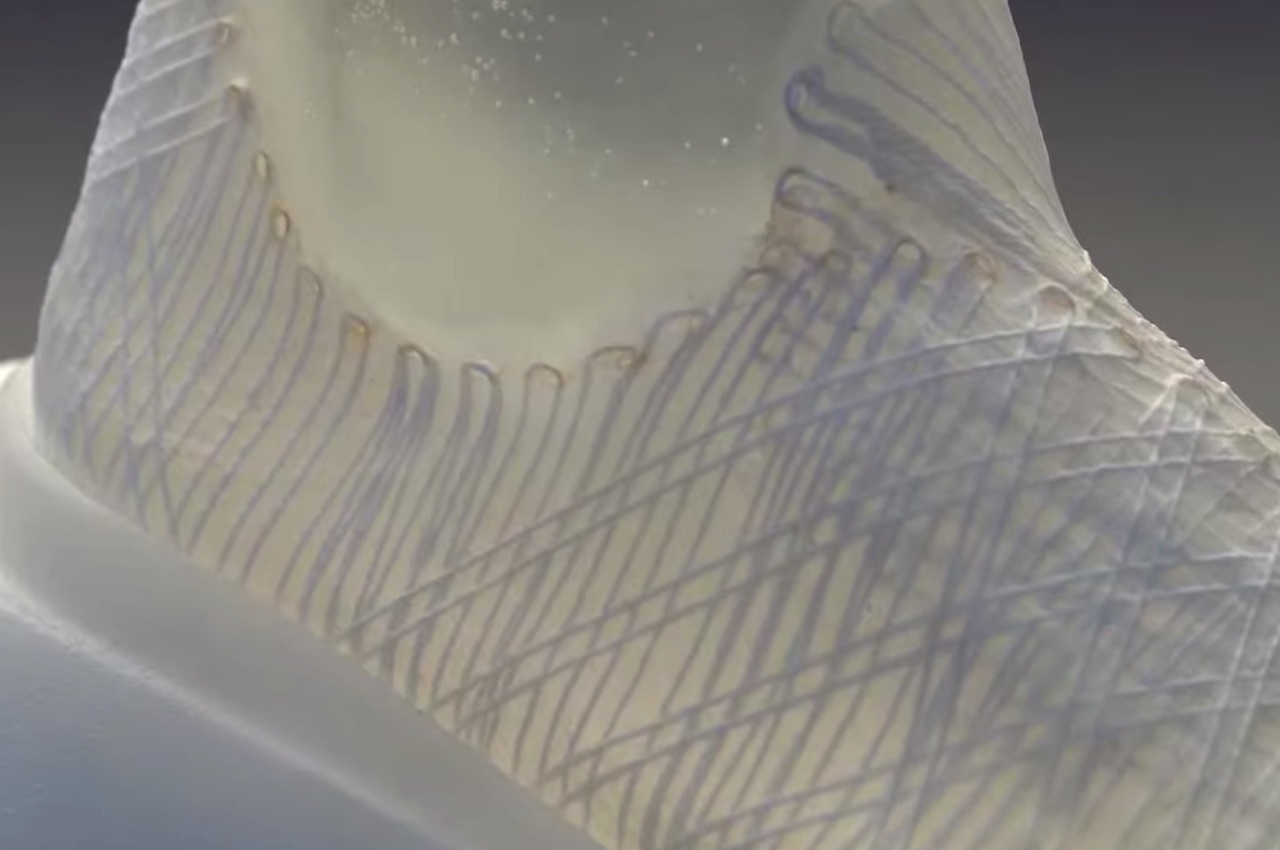

Modern Synthesis has introduced a new technology that could make biotextiles from microbes by “weaving” and “growing” a kind of bacteria known as k.rhaeticus— the type found in kombucha tea so the idea is natural. The company developed a microbial weaving process (still patent-pending) to create fabric and composites by simply growing microbes. There is no actual weaving that happens, as in the traditional sense of weaving, but what happens is that bacteria grow and trail tiny fibers of nanocellulose to create non-woven fiber.

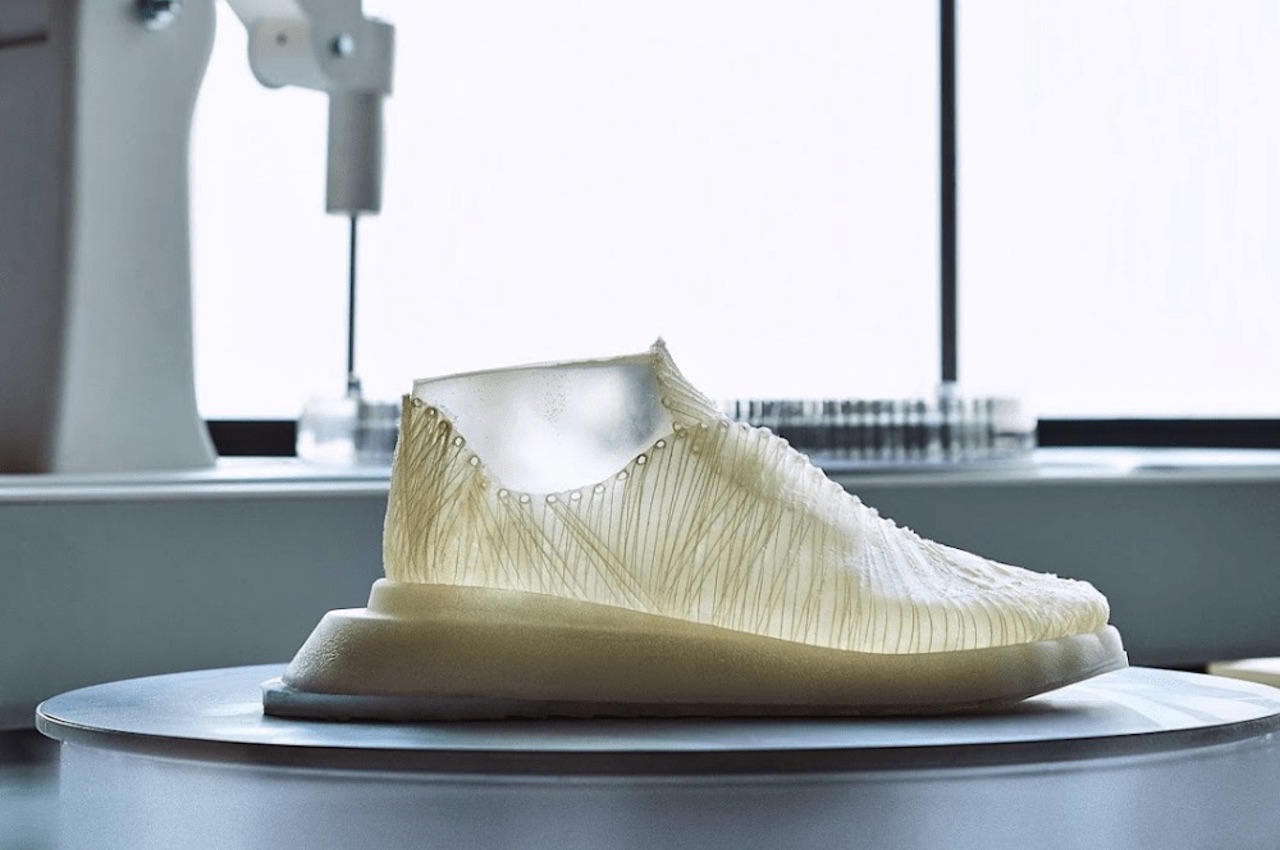

Bacteria grow the fabric material over time and take the shape of a scaffold if there is a need to create shape or form. The scaffold acts as the structure where the microbes can grow into a biomaterial that is strong yet lightweight in form. Simply put, bacteria grown inside a container form whatever shape of structure—like magically growing fabric out of nothing. But, of course, there is no magic—just science and technology being put to good use for a better planet.

This microbial weaving can be likened to 3D printing because it can also be used for shoes, as explored by founder Jen Keane back in 2018. The shoe business is just one possible application, but we can imagine this process to be used in other industries. In the near future, we hope to learn about a top sportswear brand using this process as Modern Synthesis recently shared its prototyping process and materials with a certain unknown company.

Modern Synthesis’ goal is to further contribute significantly to a circular economy and as Keane explained in a report: “At the end of the day, we’re trying to build a circular manufacturing system with these microbes. That enables us to leverage agricultural waste, use the microbes as manufacturing units, and transfer them into more viable materials. On the flip side, we see the opportunity to have new-class materials that are fully cellulosic so we can recycle them back into silos and recycling stream.”

Replacing those animal and petrochemical-derived materials is also the startup’s goal, so we believe the efforts of everyone involved will not be in vain. Many people are hopeful this microbial textile technology will remarkably help the fashion industry lower its carbon print. Using bacteria to transform into nanocellulose from sugar obtained from agricultural waste is one innovative development we hope can also be applied in many industries.