Despite their dangers to the environment, the use of plastics is still on the rise. The material does have desirable properties that make it too easy to ignore their long-term harmful effects on our planet. Recycling plastic products, especially PET bottles, is always an option, but the costs and energy involved make many businesses and individuals just turn a blind eye to the growing problem. What if you could recycle these bottles on your own at home? What if you could use these PET bottles as the very material to create other things? That’s the almost perfect circular economy that this open source machine is trying to make a reality, and the machine itself is 3D printed using the very same material it recycles.

Designer: Reiten Cheng

3D printers have democratized the manufacturing and production industry, allowing almost anyone with enough resources to create the objects of their dreams. While it’s nearly possible to use a variety of filaments as printing materials, the most common are still thermoplastics like PLA and ABS. These only add to the growing number of plastic-based products out in the wild that will eventually end up in landfills. There is now another way to get plastic filaments without having factories churn out fresh new ones.

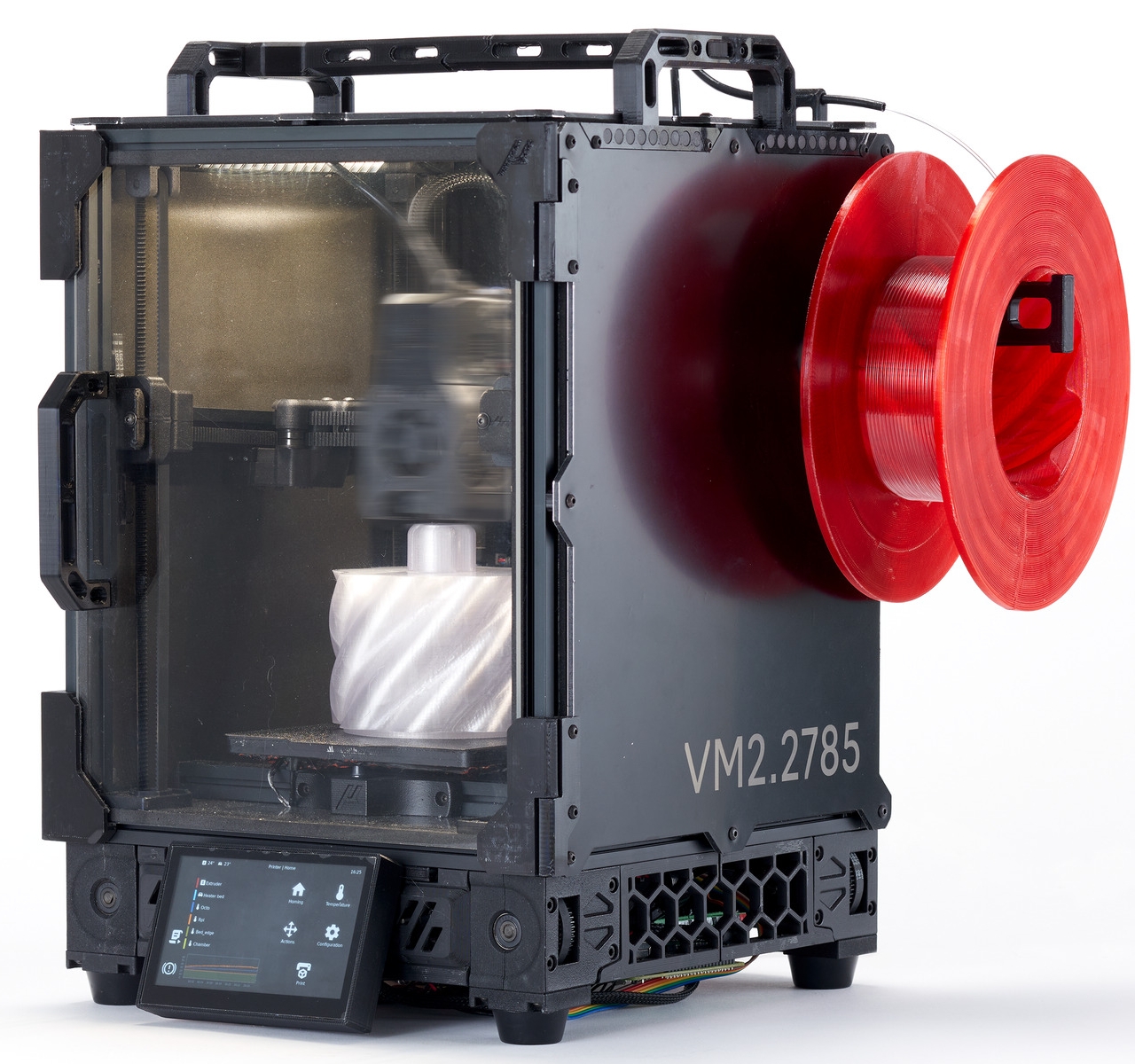

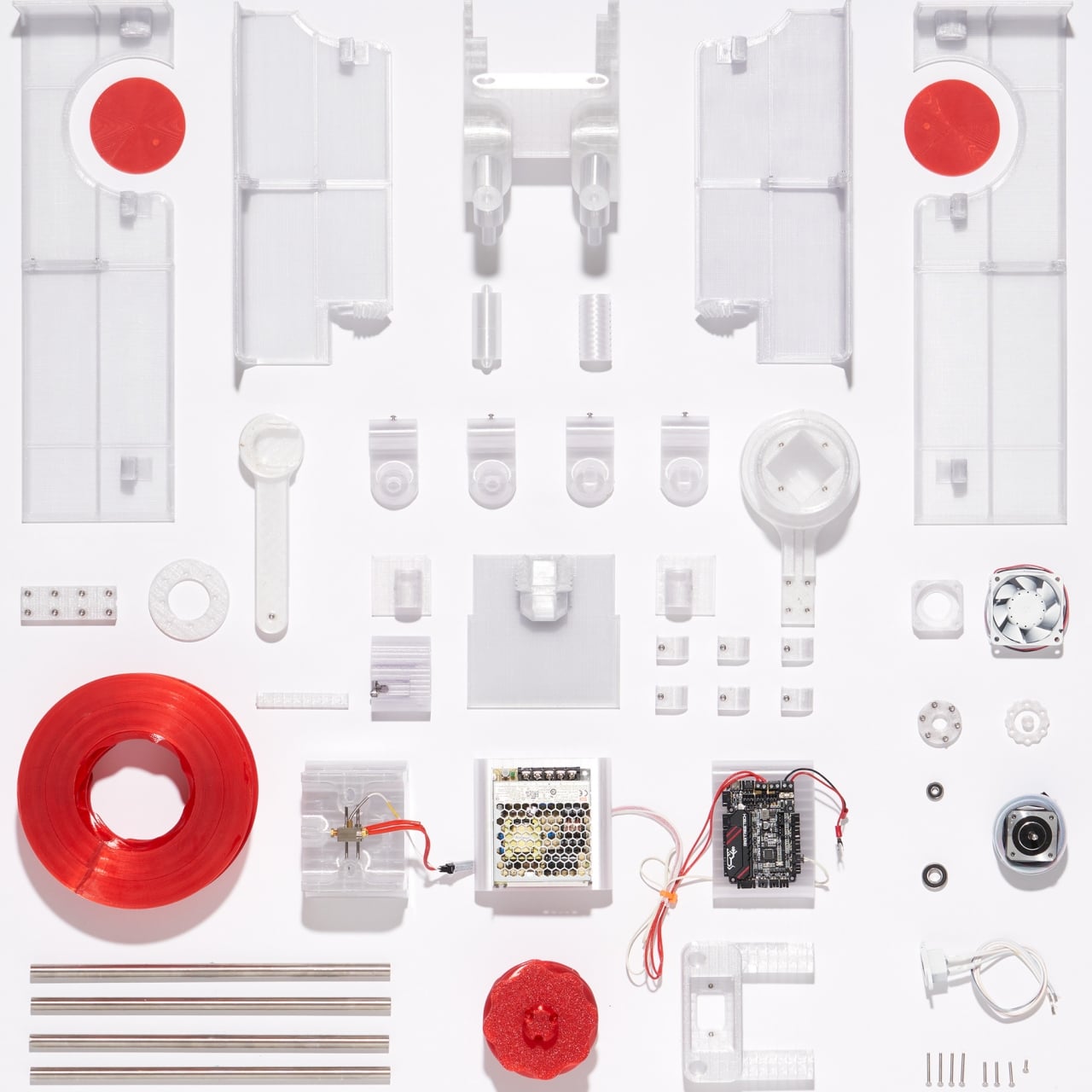

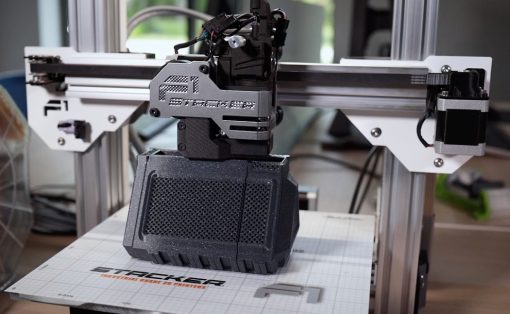

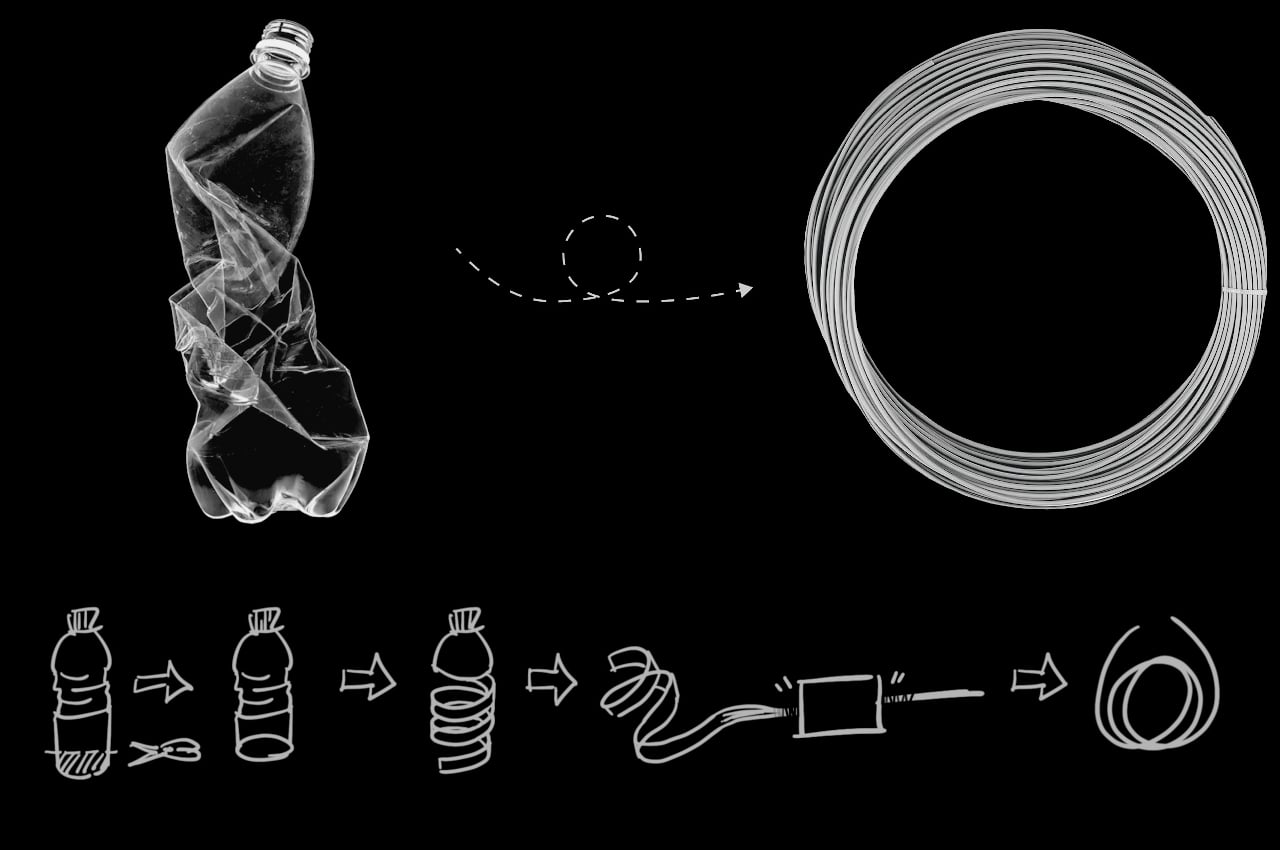

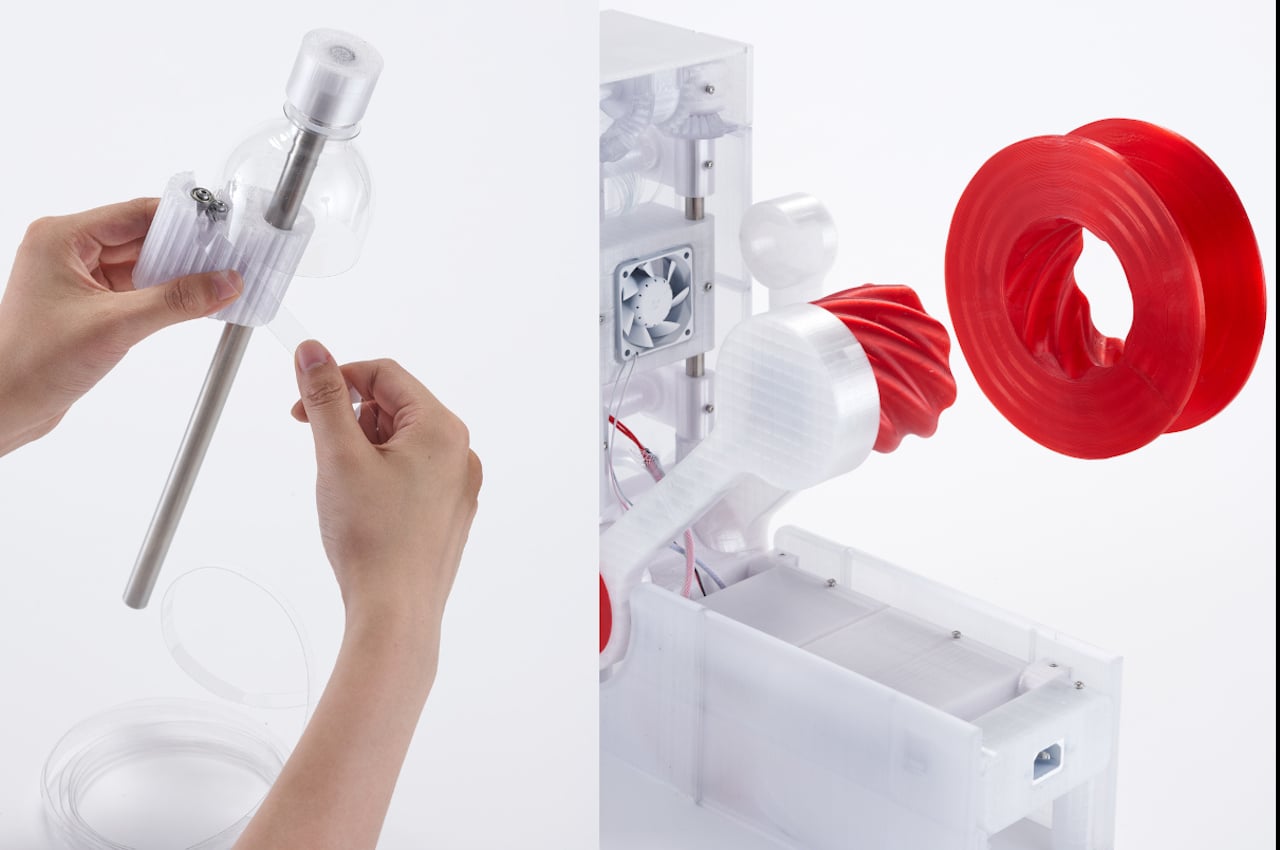

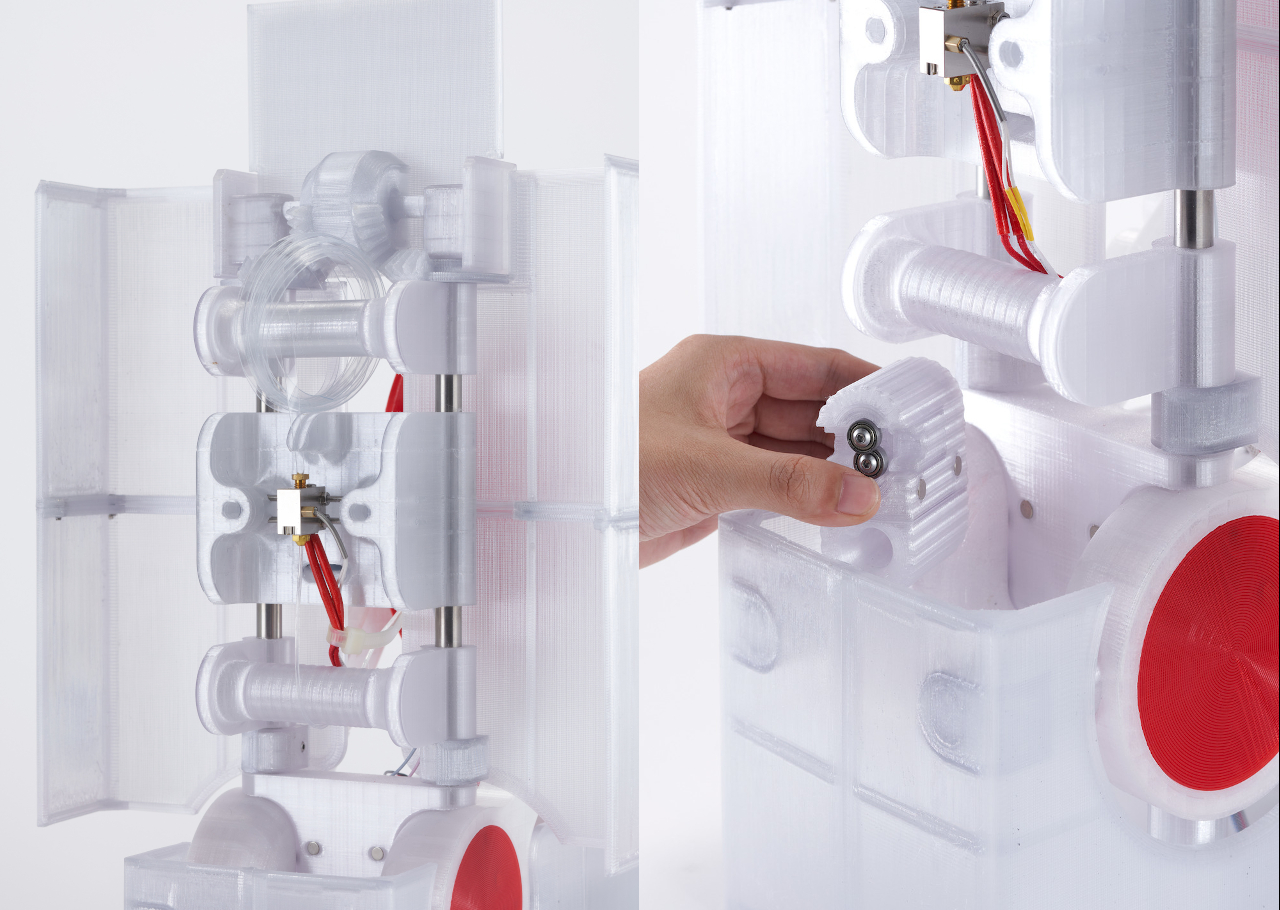

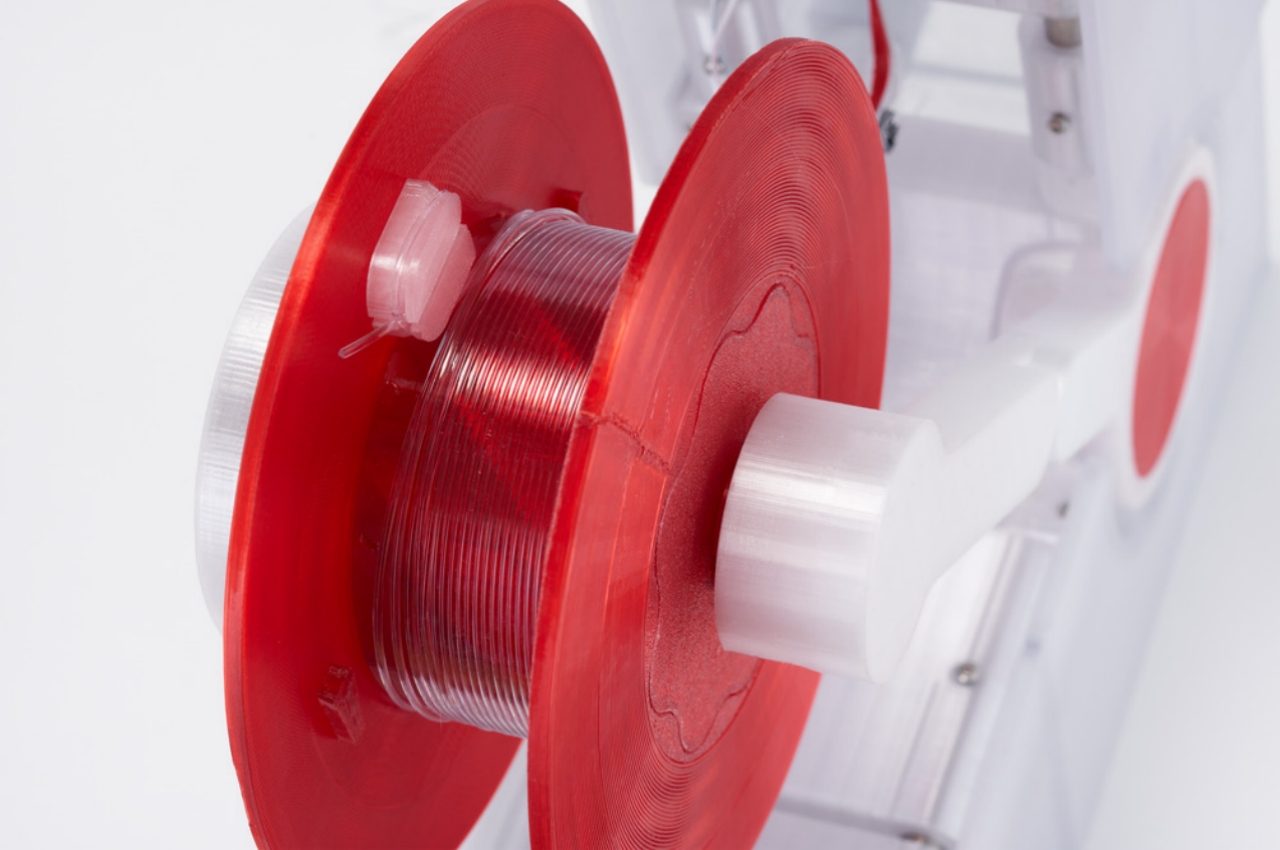

The Polyformer looks interesting from the get-go, and its name sounds like something taken out of fictional literature. Its translucent white appearance is thanks to the fact that it is made from recycled plastic PET bottles, giving it an appearance that also speaks to its purpose. In a nutshell, the machine slices up PET bottles and melts them to turn them into filaments only 1.75 mm in diameter. These recycled plastic threads can then be used in normal 3D printers to create more things, probably with the same distinctive translucent appearance as the Polyformer.

This is a rather ingenious and creative way to reuse plastic bottles, especially if you’re the type to use a lot of plastic material in 3D printing. If this kind of upcycling becomes more popular, it could help reduce the creation of virgin plastic for the purpose of 3D printing. At the same time, it offers an alternative to the traditional way PET bottles are recycled. Although those can be done en masse, the process often requires long-distance transportation and more water and energy. This way, you can do your own small part in making sure those bottles get a second lease on life.

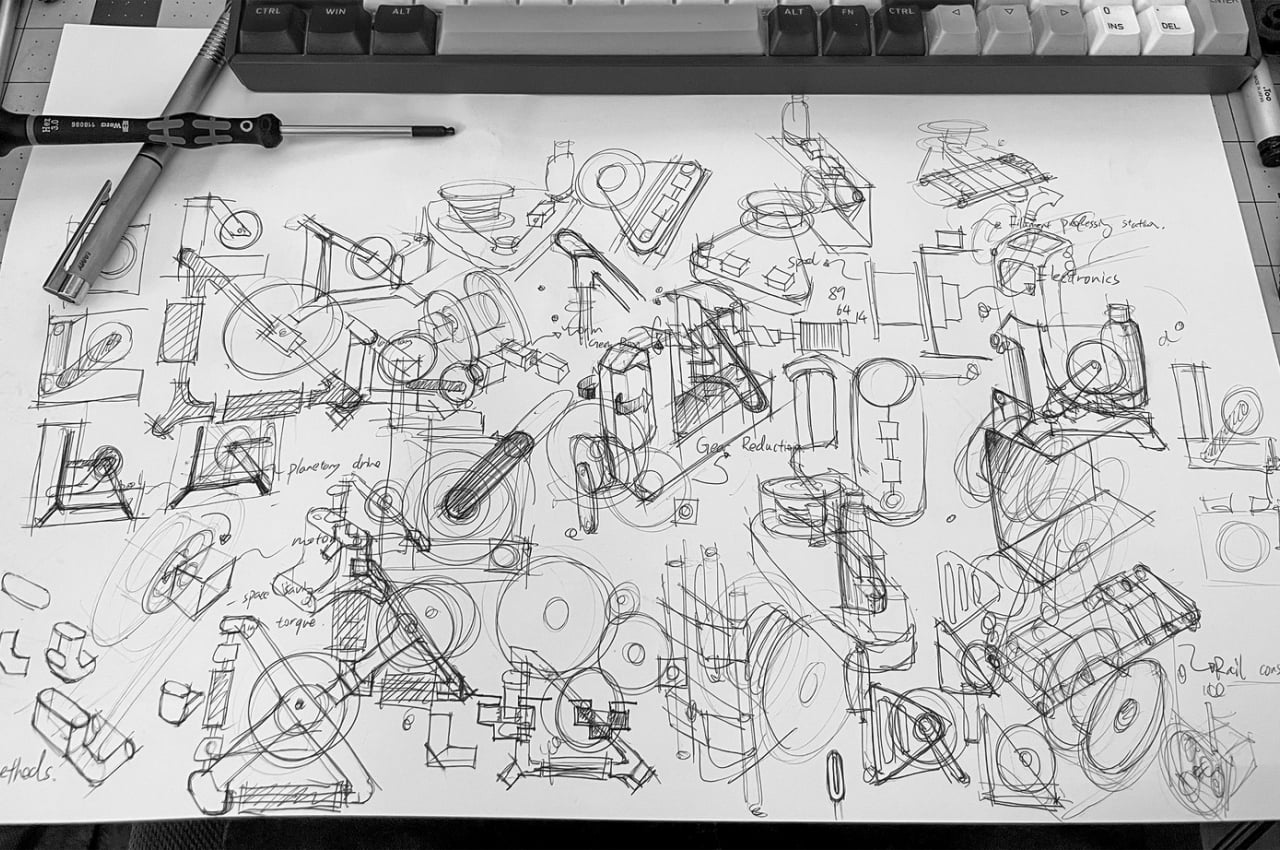

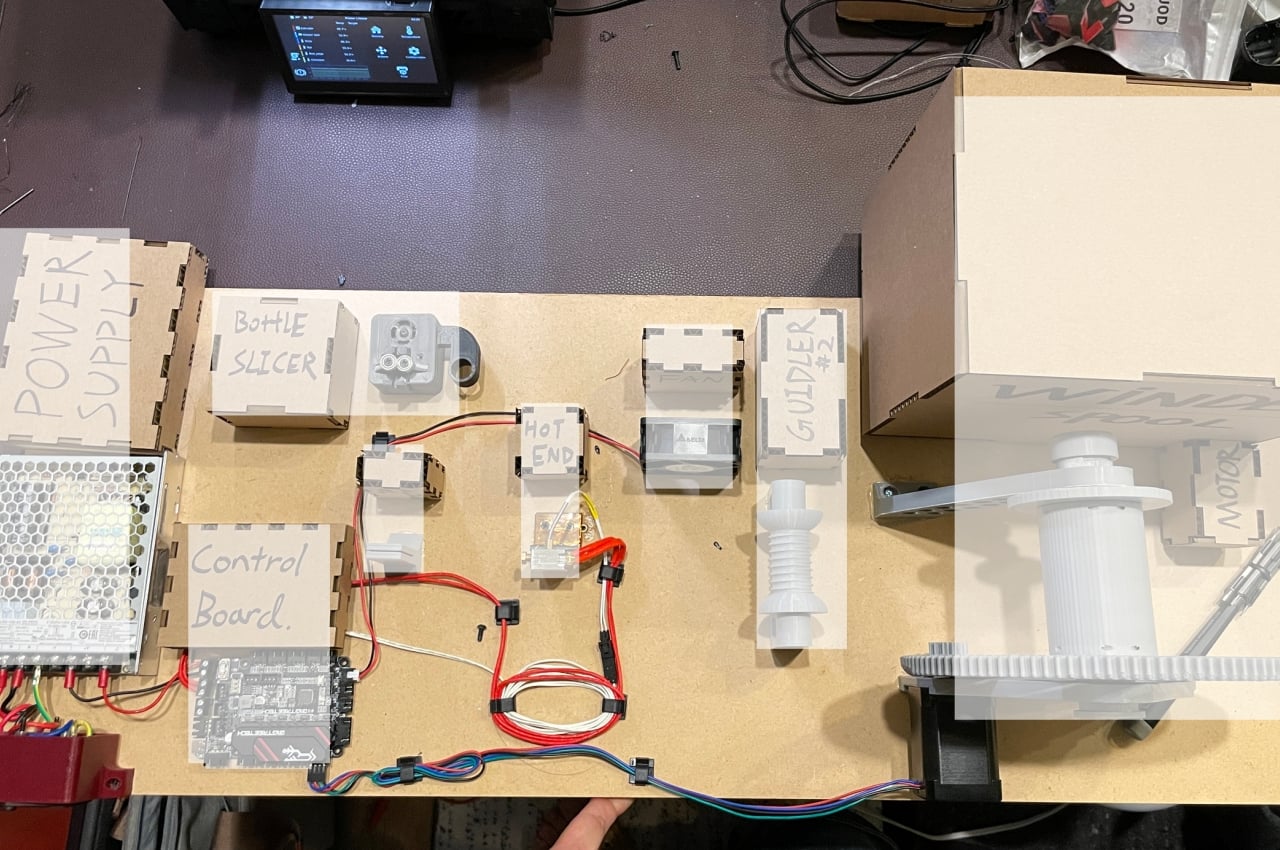

The best part about this 3D printed upcycling machine is that its designer has made available all the information needed to recreate it yourself. In addition to 3D printed parts, the Polyformer also utilizes components used in normal 3D printers that could be bought off the shelf. The design is also modular, making it easy to swap out parts and customize the design to one’s needs and tastes. Hopefully, the idea catches on and, like in open source software, gets improved on by the maker community so that there could be more sustainable sources for the materials that, in turn, form other products from these creative minds.