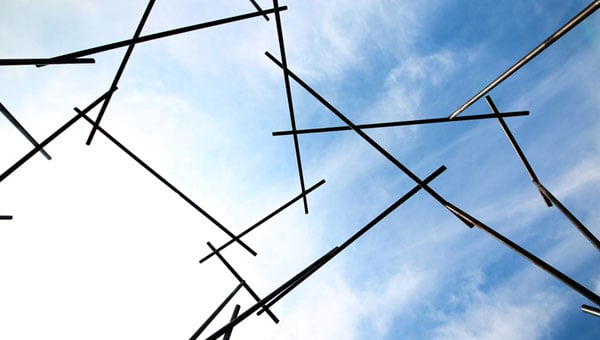

It warms our core when we come across some inspiring case studies. Just like this one that solidThinking shared with us, involving their ‘Inspire’ software and Columbia University’s Studio-X and Tokyo DIGITAL STUDIO. The project (a pavilion) was collaboration between the two and showcased at the Tokyo Designers Week 2013 and 2014. The structural optimization software helped generate a buildable complex shape that increased the stability performance of the pavilion.

[youtube:https://www.youtube.com/watch?v=bolX51z8p3Q 600 451]

According to Daisuke Hirose (Manager of Studio X, Director of Archicomplex Inc. and Professor at DIGITAL STUDIO, Tokyo), “Adopting Inspire for structural optimization in the first stage allowed us to fabricate a better model that simultaneously addressed strength and stability.”

- The concept of the pavilion was defined with an investigation on material waste reduction focusing on the evaluation of structural aspects like stability and instability.

- Thanks to Inspire, DIGITAL STUDIO simultaneously addressed the stability of the pavilion and also provided further optimization of the shape’s components.

- The design gradually evolved into a material waste reduction, minimizing the use of structural components.

- After the initial configuration using 3D modeling tools, Inspire was used to perform structural optimization.

- The result of the optimized model was then refined using 3D modeling tools to define the optimal structure of the pavilion adopting pipes.

- The pipes were cut out using a multi-axis laser cutter and then assembled.

- In Inspire, the setup of the optimization for the initial shape was based on the following conditions; first, the stress result was determined by applying the self-weight of the entire volume as a fixed load.

- Next, DIGITAL STUDIO made simple assumptions to simulate wind pressure and seismic study to evaluate the structure in-depth.

- Four lateral loads, from main directions, were applied to the model to simulate wind and seismic actions and obtain the final stress results.

- Four different analyses were carried out combining self-weight with a lateral load each time.

- Although different from a dynamic analysis, our assumption, a sort of multidirectional analyses, generated stresses that can occur in a building in similar conditions.

- Finally, the results of the four analyses were combined together, with a Boolean sum, to generate the final optimal model.

- The fabrication model was based on the model generated in Inspire.

- All polygons’ center points were extracted onto the surface.

- More than 3000 points were extracted to create lines along the optimized model then turned into pipes for the final fabrication.

- The fabrication model was based on the optimized structural model made in Inspire; therefore, it maintains its structural strength.

- The final model created was evaluated from various angles, and finally the pipes were placed.

- The pipe bonding process involved 3D CAD, but no welding.

During the project, DIGITAL STUDIO discovered that Inspire’s optimization technology was actually the result of extensive research about the growth of the human bones. The same principle of optimization can be easily applied to structural design. As a result, not only can the form be obtained without special skills on structural mechanics, but also a complex shape can be captured and optimized as a more realistic structure.

Software: solidThinking Inspire