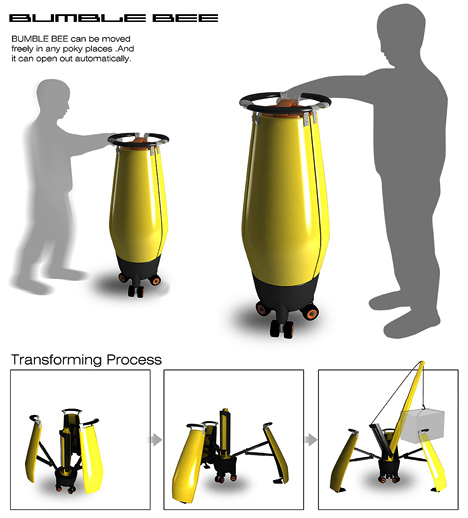

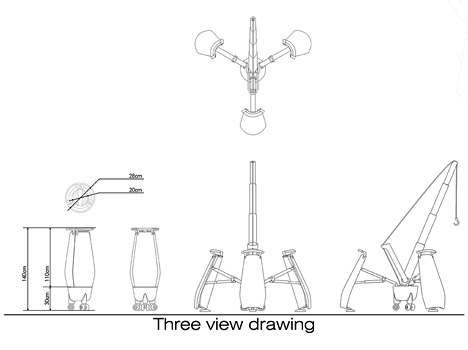

Have you heard of the latest Buzz? It’s about this Bumble Bee that doesn’t sting! Poor thing lost its stinging prowess to lifting heavy weights. Honestly, it’s just a pint-sized crane that does what most cranes do… the only difference is its compact size and Transformer-like capabilities. From a cylinder it expands out to a full-fledged crane! Yippee! Good for indoor hauling.

Designers: Yuan Biao, Qiu Meng, Liu Xiao & Tang Gang